Page 4 of 5

Re: Greenie rebuild issues

Posted: Sat Apr 10, 2021 1:15 pm

by ssmall

I lubed the sheaves with some Kroil and installed the motor and drive belt. It works like a charm.

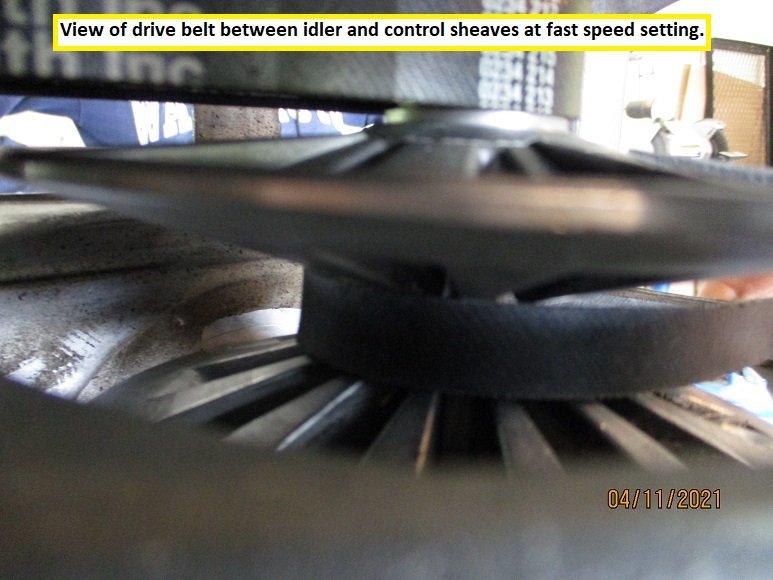

That said, I found while adjusting the speed control, it's possible to adjust too far to the fast side. When the speed control is adjusted past where it should stop on the fast side, it binds up the drive belt by allowing the idler sheaves to seperate enough that the drive belt slips deep into the interior portion of the sheaves thus causing the binding.

This is my best guess as I found nothing wrong except the drive belt was bound up.

Re: Greenie rebuild issues

Posted: Sat Apr 10, 2021 1:52 pm

by rpd

ssmall wrote: ↑Sat Apr 10, 2021 1:15 pm

I lubed the sheaves with some Kroil and installed the motor and drive belt. It works like a charm.

That said, I found while adjusting the speed control, it's possible to adjust too far to the fast side. When the speed control is adjusted past where it should stop on the fast side, it binds up the drive belt by allowing the idler sheaves to seperate enough that the drive belt slips deep into the interior portion of the sheaves thus causing the binding.

This is my best guess as I found nothing wrong except the drive belt was bound up.

Download #13 How To Do a High Speed Adjustment

http://allinonewood.com/?page=shop/serviceadvisor&

Re: Greenie rebuild issues

Posted: Sat Apr 10, 2021 2:29 pm

by JPG

Motor pulley belt jamming at high speed with no control sheave interfering with the speed control bracket indicates the belt may be worn too narrow. The width at the widest should NOT be less than 1/2".

Re: Greenie rebuild issues

Posted: Sat Apr 10, 2021 4:56 pm

by ssmall

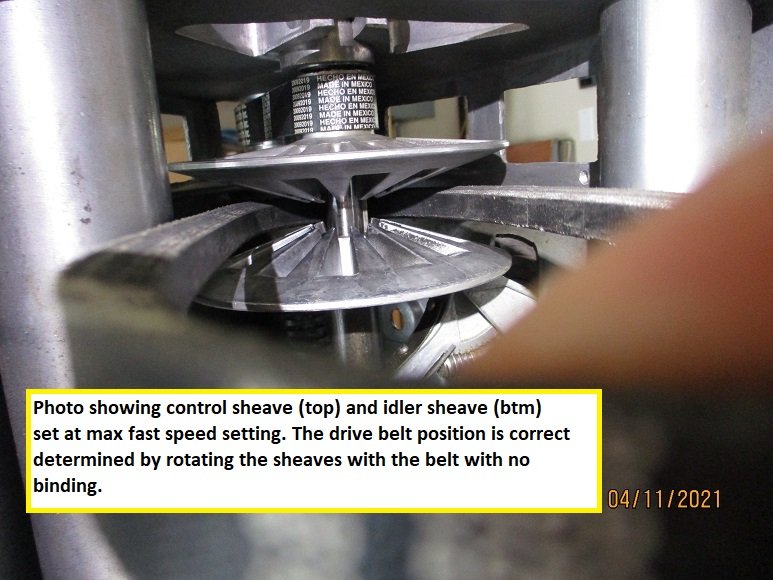

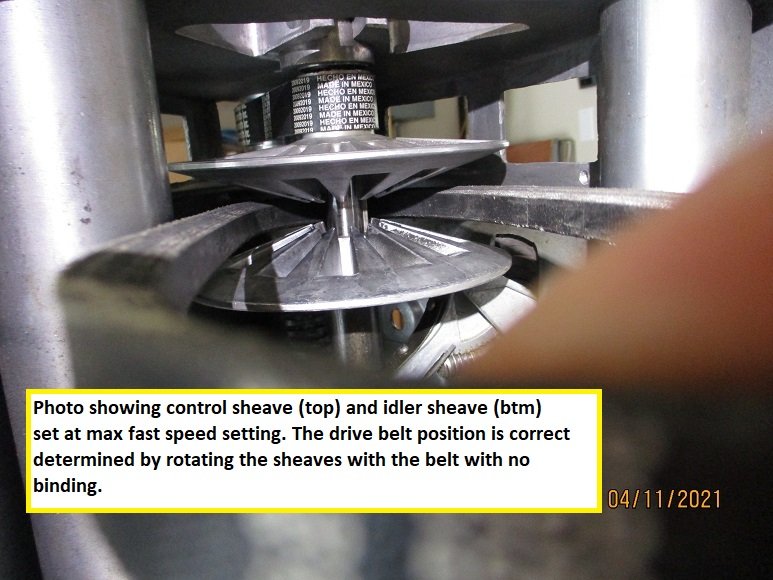

This photo shows the Idler Sheave in the max speed (fast) position. I have had issues with one of the two idler sheaves slightly rotating, then when a slower speed is adjusted thus causing the idler sheaves to close together, the teeth of the idler sheaves do not align and cause binding.

When the Greenie works it works well, however it does not take much to create the binding problem. I will perform the High Speed adjustment and hopefully that will do the trick.

Thank you all for your assistance, I greatly appreiciate it!!!

Re: Greenie rebuild issues

Posted: Sat Apr 10, 2021 4:59 pm

by ssmall

The photo I forgot to attach to my last post. It shows the idler sheave in the max speed (fast) position.

- IMG_7150.JPG (83.88 KiB) Viewed 998 times

Re: Greenie rebuild issues

Posted: Sat Apr 10, 2021 5:49 pm

by JPG

That idler pulley pix at high speed has a couple of 'issues'.

The pulley appears too far open. When assembled, where is the motor belt riding on the motor pulley under this setting?

The 'vanes' of the control sheave appear to align with the 'vanes' of the idler sheave. The vanes should align with a void in the opposing sheave. Is the key assembled on the idler shaft? Has the control sheave slipped past the end of the key?[is the control sheave free to rotate independently from the shaft?????]

Re: Greenie rebuild issues

Posted: Sat Apr 10, 2021 5:56 pm

by DLB

There should be a key in the idler shaft preventing sheave rotatation relative to the shaft or each other. If you can rotate the idler looking between the sheaves the way you have it in the picture you should see either a key or the keyway.

Just for confirmation, you've replace both idler shaft sheaves, is that correct? And were both new parts from SS? But the motor sheaves are older, potentially from the original Greenie?

A high speed adjust is only going to solve part of the problem IMO. The binding that occurred at a moderate speed is something else, I think. Were you changing speeds when it bound up?

I see jpg is thinking the same way, but I'm leaving this in case it adds some clarity.

- David

Re: Greenie rebuild issues

Posted: Sun Apr 11, 2021 10:42 am

by ssmall

The pulley appears too far open. When assembled, where is the motor belt riding on the motor pulley under this setting?

The 'vanes' of the control sheave appear to align with the 'vanes' of the idler sheave. The vanes should align with a void in the opposing sheave. Is the key assembled on the idler shaft? Has the control sheave slipped past the end of the key?[is the control sheave free to rotate independently from the shaft?????]

Just for confirmation, you've replace both idler shaft sheaves, is that correct? And were both new parts from SS? But the motor sheaves are older, potentially from the original Greenie?

A high speed adjust is only going to solve part of the problem IMO. The binding that occurred at a moderate speed is something else, I think. Were you changing speeds when it bound up?

When the drive belt binds up it is caught on the Sheave vanes. I concur the sheave halfs should not rotate seperately as there is a key that is supposed holds them in line with eachother.

Yes both the control sheave and idler sheave have been replaced with new ShopSmith parts. The original greenie motor sheaves were in good condition and operational and thus were not replaced at rebuild.

Actually the binding was during operation at the fast speed setting with no speed adjusting taking place when the drive belt bound up. This leads me back to the mis-alignment of the idler and control sheaves.

I'm going to open it back up and investigate why the idler and control sheaves are able to move independant of eachother.

Re: Greenie rebuild issues

Posted: Sun Apr 11, 2021 11:37 am

by JPG

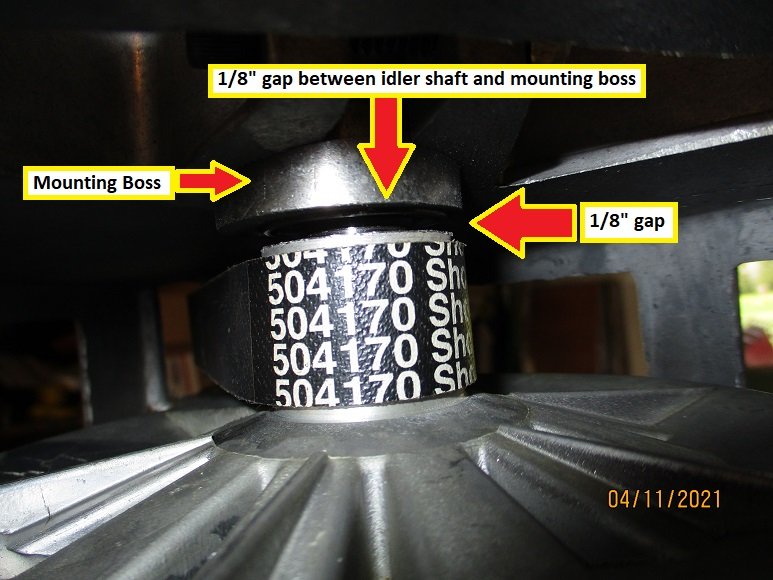

I am redirecting my suspicion(original suspicion appears to have been verified) to the positioning of the idler shaft bearing etc.

Re: Greenie rebuild issues

Posted: Sun Apr 11, 2021 12:14 pm

by ssmall

I am redirecting my suspicion(original suspicion appears to have been verified) to the positioning of the idler shaft bearing etc.]

You hit the nail on the head!

I found the idler shaft key to be properly installed and locking the two sheaves. Still not clear why they were able to rotate seperatly before, but they are locked together now.

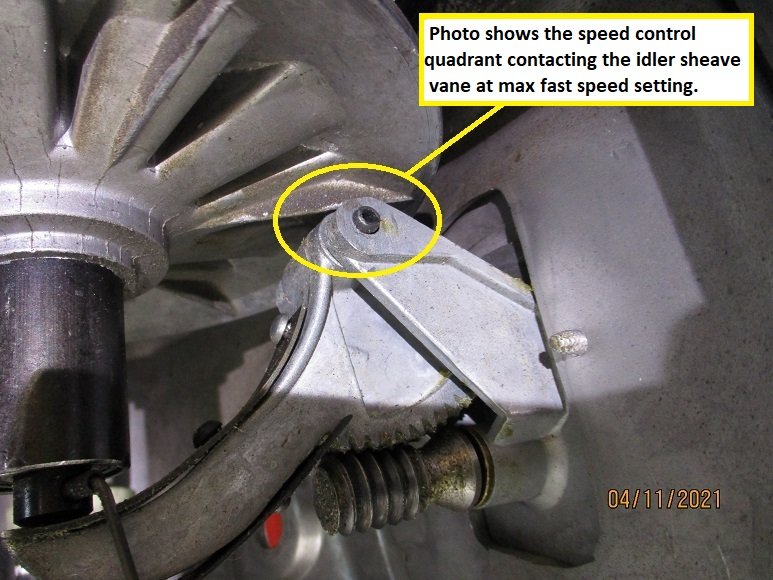

I found a 1/8" gap between the idler shaft mounting boss and the idler shaft that was causing the Speed control quadrant assembly to contact the idler sheave vane.

I atempted to adjust the idler shaft up towards the eccentric bushing by loosening the eccentric bushing boss bolt, however this only allowed the control sheave to move up and not the bottom sheave (idler sheave).

I checked for proper drive belt placement between the sheaves at max fast speed setting and it looked good as well as operated freely with no binding.

For now the fix will to be careful not to drive the speed control to max fast, thus eliminating the possiblity of jamming the idler sheave into the speed control quadrant.

- IMG_7158.JPG (85.08 KiB) Viewed 956 times

- IMG_7162.JPG (83.34 KiB) Viewed 956 times

- IMG_7160.JPG (91.03 KiB) Viewed 956 times

- IMG_7161.JPG (95.76 KiB) Viewed 956 times

- IMG_7157.JPG (72.92 KiB) Viewed 956 times

- IMG_7158.JPG (85.08 KiB) Viewed 956 times