Page 5 of 10

Re: A view on alignment of the shopsmith.

Posted: Thu Jan 21, 2021 11:45 am

by dusty

It is possible that those comments weren't directed at you, RFGuy.

This is why I often quote a specific member rather than leaving it for the membership to figure out who my comments are directed at.

Re: A view on alignment of the shopsmith.

Posted: Thu Jan 21, 2021 12:16 pm

by dusty

'll bet that this will work a lot better if I insert a pivot point between the Extension Table and the Main Table right inline with the spindle.

Theory being that the direction one side moves when the other is pushed/pulled will be predicable. Right now the Main Table moves in response to a stop collar adjustment but where.

- Needs a Pivot Point

- 20210121_084641.jpg (391.17 KiB) Viewed 996 times

Re: A view on alignment of the shopsmith.

Posted: Thu Jan 21, 2021 12:38 pm

by JPG

Hokay! Did not mean to get thee more riled up.

Yes I tend to speak less than 'precisely' at times and tend to speak in a self depreciating manner. Not to be critical of anyone else, but to keep my own ego under control(Dusty will disagree with that bur that is his thing). Yes I do say things by inference that are not always obvious to others.

I DO understand why you were questioning your readings. They did not make sense. I hope this thread has cleared up thy understanding.

I feel a bit like the Andy Griffith commercial on "METV" re decoding what he is talking about(nervious as a long tailed cat in a room full of rocking chairs).

I prefer plain language that is non-pretentious.

Now about the magnifying glass - A dial indicator that reads on 1/1000th gives view of very small deviations that are IMO nits. I agree that seeking as much precision as possible is admirable, but not an end in itself. I consider the SS tool kit in the miter gauge with a single tooth on a saw blade as adequate. I also consider the combination square against the edge of a miter gauge slot and the rip fence adequate as well. My observations include that the sides of the rip fence are far from straight anyway. I only look at the ends. A good check is feeling the 'joint' between the slot and the side of the rip fence.

Re: A view on alignment of the shopsmith.

Posted: Thu Jan 21, 2021 12:43 pm

by JPG

Well Dusty now we know why thee are seeking a 1" version of the micro adjuster. A hopefully better method of adjusting than tapping with a blunt object.

I like the idea.

Re: A view on alignment of the shopsmith.

Posted: Thu Jan 21, 2021 2:42 pm

by edflorence

jpg wrote:

I also consider the combination square against the edge of a miter gauge slot and the rip fence adequate as well.

That has worked well for me for a long time. I do own a dial indicator and once in a while dig it out, but I have not found the results of using it to be better than using the combination square. jpg's method is my "go to" method for alignment. Early editions of PTWFE even said that a combination square against the edge of the main table would work.

And checking the offset of the face of the rip fence from the edge of the adjacent miter gauge slot with the combination square is for me a routine part of the operation of placing the rip fence. Using the square for these checks is quick and easy and gives good results.

Re: A view on alignment of the shopsmith.

Posted: Fri Jan 22, 2021 12:58 pm

by JPG

DUSTY....

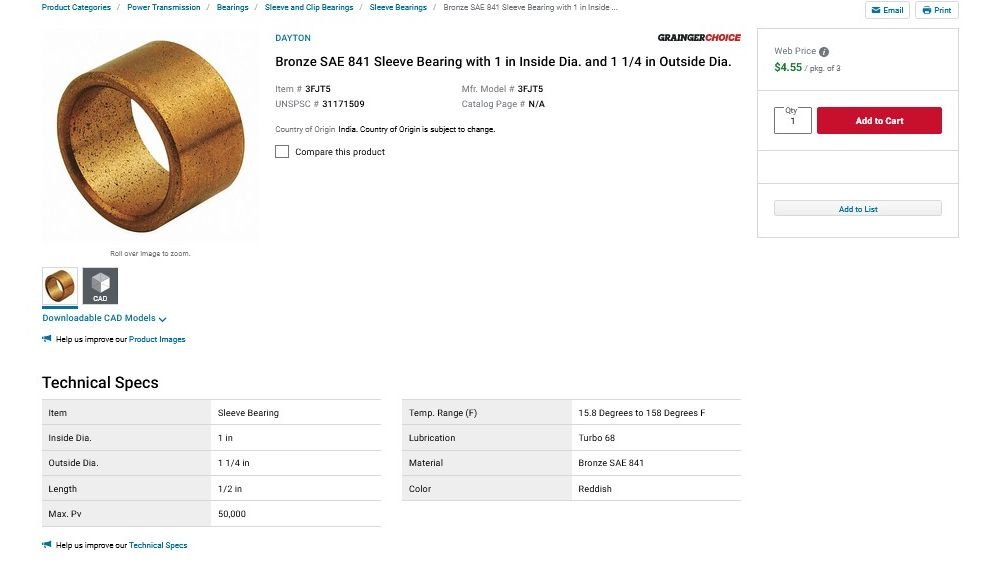

- 1 to 5.4 bushing.jpg (57.96 KiB) Viewed 952 times

Re: A view on alignment of the shopsmith.

Posted: Fri Jan 22, 2021 1:09 pm

by JPG

dusty wrote: ↑Thu Jan 21, 2021 12:16 pm

'll bet that this will work a lot better if I insert a pivot point between the Extension Table and the Main Table right inline with the spindle.

Theory being that the direction one side moves when the other is pushed/pulled will be predicable. Right now the Main Table moves in response to a stop collar adjustment but where.

20210121_084641.jpg

A 'pivot' between the two tables would work better IF the collars were 'pulling'.

Since they 'push' a pivot needs to be on the other side of the main table.

If ya leave one bolt 'snug' it can be the pivot point.

Ideally the pivot location would be mid point rather than the quill (EQUAL/opposite direction).

Re: A view on alignment of the shopsmith.

Posted: Sat Jan 23, 2021 6:57 am

by dusty

It worked well! End of Story

Loosened all four trunnion bolts.

Push Main Table Hard Right.

Installed Pivot Point.

Checked For Parallelism With Blade.

Tweeked the Infeed Stop Collar.

Secure Trunnions/Main Table.

Rechecked for Parallelism.

Done.

That's My Story and I'm Sticking To It.

Re: A view on alignment of the shopsmith.

Posted: Sat Jan 23, 2021 8:19 am

by JPG

Where / how did you create the pivot point?

Re: A view on alignment of the shopsmith.

Posted: Sat Jan 23, 2021 8:41 am

by dusty

A c-clamp attach to the extension table in-line (between the two tables) with the spindle.