Page 2 of 3

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Fri Apr 10, 2015 9:35 pm

by reible

Today was mount the saw day.

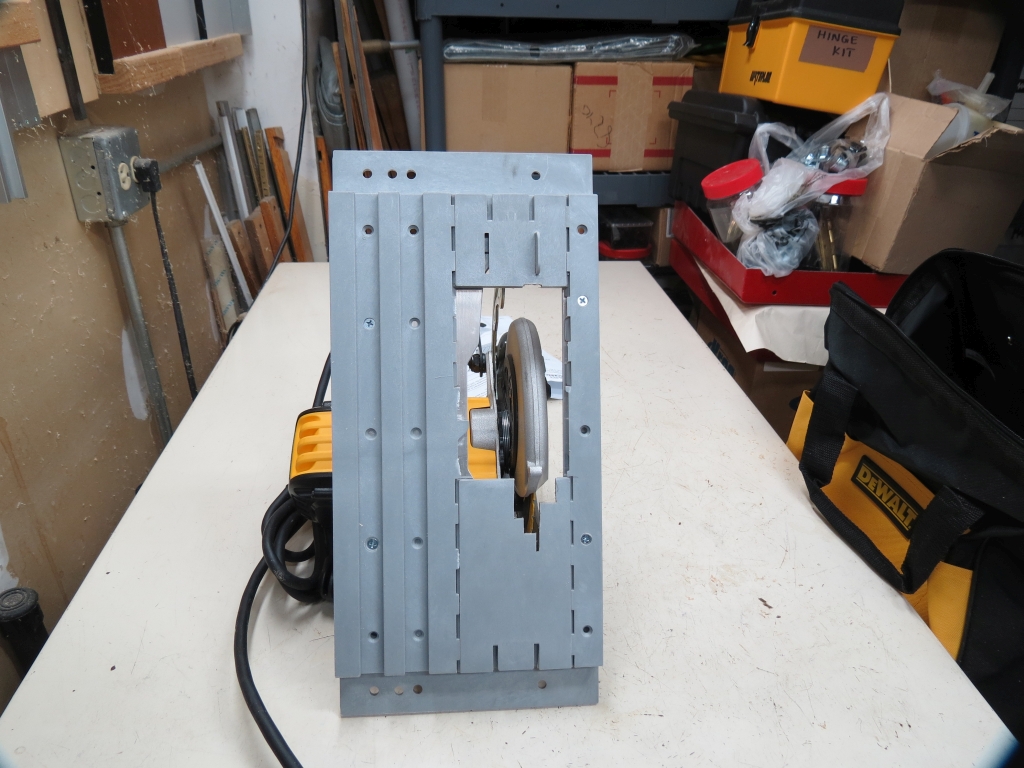

Sole picture first. Not much to see but there it is. How much cutting out of the inserts and screw locations are saw and user dependent.

- IMG_6651sc.jpg (497.87 KiB) Viewed 13904 times

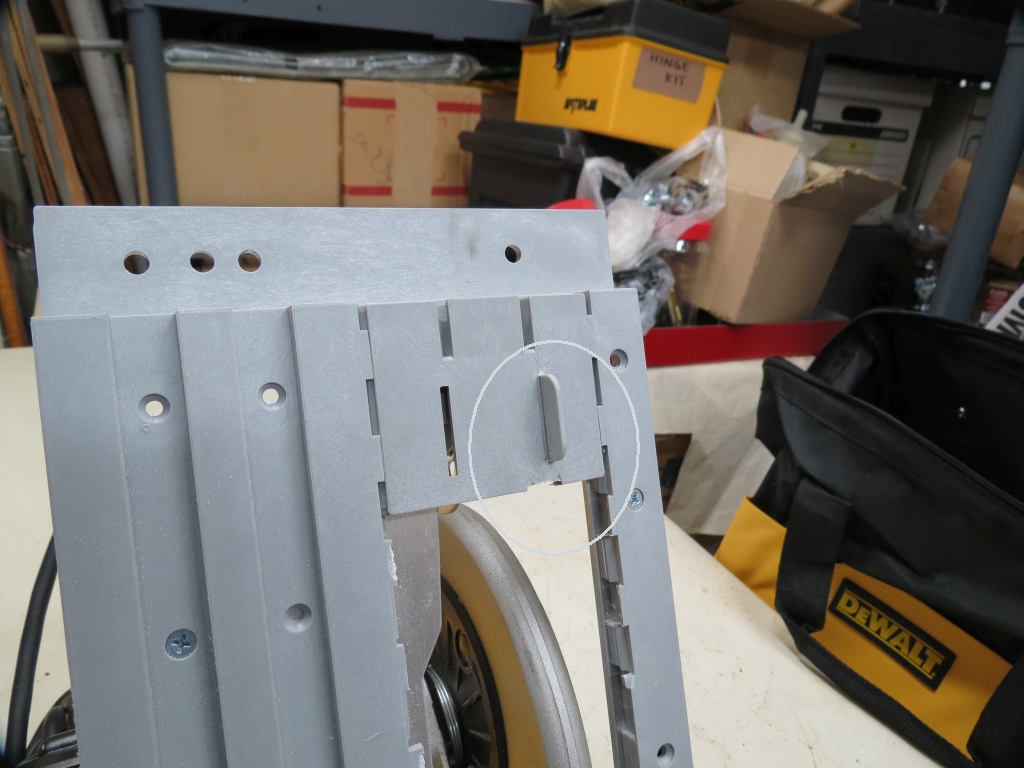

The zci area and the cut out for the blade guard are indicated by the oval. I used my bandsaw to make the clearance and the zci area is cut by the saw blade by plunging into it. The insert is replaceable if it is damaged or if you change saws or change blades. I'm deciding if it is worth having a couple of spares or not.

- IMG_6652sc.jpg (472.79 KiB) Viewed 13904 times

In my case the blade guard also required me to take a small amount of the insert where the "fin" goes. See the oval. As I expected the fin is to wide and will have to be adjusted to the blade kerf size. I have not done this yet.

- IMG_6653sc.jpg (476.01 KiB) Viewed 13904 times

In the next two photos you can see where I picked to place the mounting screws. I did tap them on my first go around but thought more about it and decided to make them thru holes and put the lock nuts on. I feel safer with the lock nuts in place and I can see if they look like they are coming loose rather then getting a nasty surprise..... but again that is just me.

- IMG_6654sc.jpg (522.63 KiB) Viewed 13904 times

- IMG_6655sc.jpg (541.4 KiB) Viewed 13904 times

I did mount the saw plate to the complete the project but the camera battery wasn't up to taking any more photos tonight.

Next I have to thin the "fin" and check out how to adjust where the cut line is in relation to the actual cut. And well I will at sometime have to test it out on some real plywood. Not sure when that will happen as I have no sheet goods to cut up.

Ed

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Sat Apr 11, 2015 2:02 am

by JPG

Tapped plate AND a nut!

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Sat Apr 11, 2015 11:55 am

by roy_okc

Ed,

The fin was designed for use in situations where the material might close behind the saw cut, such as ripping stock that is standing up rather than laying flat or ripping dimensional material that might close as internal wood stresses are relieved by the cut. You may find you don't need nor want it while cutting typical sheet goods on a flat surface.

Roy

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Sat Apr 11, 2015 1:55 pm

by paulrussell

This is on my list of "tools I need." I'm not sure I want to use my existing skill saw for two reasons: 1) No dust collection. 2) I used it and a diamond blade last year to cut a dozen or so pavers and several retaining wall blocks. I'm sure the bearings took a beating.

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Sat Apr 11, 2015 2:24 pm

by reible

roy_okc wrote:Ed,

The fin was designed for use in situations where the material might close behind the saw cut, such as ripping stock that is standing up rather than laying flat or ripping dimensional material that might close as internal wood stresses are relieved by the cut. You may find you don't need nor want it while cutting typical sheet goods on a flat surface.

Roy

You might be right but I want to get it adjusted for times when I do want it installed.

I think another function is when you get to the end of the cut the fin is still in the kerf so you will have less chance of veering off, anyway I think I read that somewhere in there information or youtube video????

Today I'm yardening so I don't think I'll be working in the shop today. Stopping for lunch now but there is so much more to do to get ready for planting.

Ed

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Sat Apr 11, 2015 2:36 pm

by reible

paulrussell wrote:This is on my list of "tools I need." I'm not sure I want to use my existing skill saw for two reasons: 1) No dust collection. 2) I used it and a diamond blade last year to cut a dozen or so pavers and several retaining wall blocks. I'm sure the bearings took a beating.

I still have not completely convinced myself this is the way to go. After some practical uses I'm not sure how I will feel. I know I want something for this project so this was a reasonably priced starting place, that is unless I don't like it then that is another story.

I'm glad you brought up the dust collection part of the equation. I end up working outside on any larger projects and certainly sheets of plywood fall in the category. So I did not take dust collection as one of the considerations when picking out this system. In fact the saw I picked has no provision for dust collection. I do use a dust mask even when cutting outside and the chips will fly where they fly. If I had made that a major consideration I would have gone a different way.

As I have mentioned before I have a saw that I use for nasty jobs like cutting pavers etc. I'm using a old saw that has seen better days and I think this sort of function will kill it off one day. No reason for me to use an expensive saw in those conditions.

Ed

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Mon Apr 13, 2015 11:05 am

by Ed in Tampa

Ed

Why did you decide to go with the edge guide instead of the track? I think the track would do a better job for you compared to the edge guide. Just wondered about your choice.

Also if you go to Eurekazone.com (manufactures website) you will see they have a dust collection system you can mount on your saw. Basically you cut a small hole at the front of the blade guard and mount a plastic nozzle to attach to a vacuum. Plus they include some clear plastic that seals the front of the blade guard to base where most dust spills out.

Also the manufacture has many tutorial videos, and a forum where other users discuss the ezsmart products. Check out eurekazone.com

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Mon Apr 13, 2015 11:47 am

by dusty

Please explain, Ed. I am in the decision making mode on a commercial track system to possibly replace my home brew. This EZSmart looks good to me; especially for cutting long runs (like 8' plywood sheets). Why do you feel that a track system would be a better choice?

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Mon Apr 13, 2015 1:12 pm

by jsburger

When Ed first started this thread I took a look at the web site. The first thing that popped out was the 2 foot limit of the cut width. So if you want to cut a sheet of plywood into two 4'X4' pieces you can't. Likewise with Baltic Birch ply you can't cut a sheet in half in either direction. There are no limitations with a track system.

Re: EZSmart Universal Edge Guide w/ univ. base

Posted: Mon Apr 13, 2015 2:07 pm

by Ed in Tampa

dusty wrote:Please explain, Ed. I am in the decision making mode on a commercial track system to possibly replace my home brew. This EZSmart looks good to me; especially for cutting long runs (like 8' plywood sheets). Why do you feel that a track system would be a better choice?

Dusty

To me the track method is the surest cut,best cut, most versatile. Eureka zone makes tracks in nearly any size and the have couplers that combine tracks.

With the edge guide the saw can still drift away from the cut line. With the track the saw runs on rails and can not drift off the cut line. Plus the way the EZSmart system is built with the track you have zero clearance on both sides of the cut.

Also you can place the track any where you want it on sheet stock you do not have to contend with only a 2 ft capacity.

Lastly with the track it makes cutting tapers and producing a straight edge on the wood a snap. with EZ Smart method you no longer have to pass the wood through your jointer to get straight edge.

I viewed the edge guide as a way to rip multiple pieces of wood to the same width. Never thought of it as a way to break down sheet stock. That is why I asked Ed why he made the choice he did.

If you read the EZSmart forum you will see most guys lay their EZSmart track on the edge of their sheet stock or any wood for that matter and take a paper thin cut down the edge to insure they have perfect straight edge to start with. Once that done they then mill the wood to sizes they need.

You need to start reading the EZSmart forums those guys are just as inventive as everyone here on the ShopSmith forum is. They have some great ideas to simplify shop work and make it 100 times more precise.