Page 2 of 2

Re: ripping a bevel

Posted: Sat Apr 09, 2016 10:41 pm

by reible

If you have a copy of Power Tool Woodworking for Everyone you might want to check the section on bevel cutting to brush up on the procedure. If you don't have a copy take a look here:

http://www.shopsmith.com/academy/tblsaw ... #bevelcuts

Ed

Re: ripping a bevel

Posted: Sun Apr 10, 2016 7:05 am

by dafixer

Thanks Ed! I do have a book. I've been re-arranging my shop over the winter plus I was getting over hand surgery from last Fall so, my book is...somewhere...

Re: ripping a bevel

Posted: Sun Apr 10, 2016 11:50 pm

by skou

dafixer wrote:Thanks Ed! I do have a book. I've been re-arranging my shop over the winter plus I was getting over hand surgery from last Fall so, my book is...somewhere...

And, if you ever lose your copy, Ed just posted another.

THANKS, Ed! I'll be using it, too.

steve

Re: ripping a bevel

Posted: Wed Apr 13, 2016 2:50 pm

by everettdavis

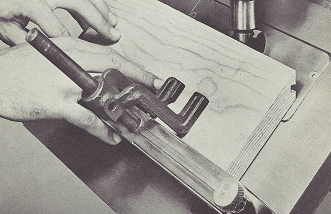

I realize the photo is for a shaping operation opposed to ripping, but one could use the same approach as here, plus add a finger board from the opposing slot or T-Slot.

Of course if you have a T-Slot you likely have a fence with one for another finger board or two, and wouldn't need a mortising hold down as we did on the 10ER and early 500's.

Just a notion, and as one man's 60 degree rip is another man's 30 degree rip to avoid that table angle for wider boards you have to rip.

Everett

- Figure 8-36.png (149.32 KiB) Viewed 5572 times

Re: ripping a bevel

Posted: Wed Apr 13, 2016 3:07 pm

by everettdavis

dafixer wrote:I'm putting a 60^ bevel on 3 pieces 7" long, 3" wide and 3/8" thick to form an equilateral triangle-shaped small tower. I kinda like the idea of using the jointer but I was wondering how to do this on the table saw for a future 4' long piece that I'll eventually cut up into 7" long pieces.

(Mark V 520, Bandsaw, Jointer/Planer, Scroll Saw, DeWalt 733 planer.)

If it were me, I would put the bevel on 1 piece just over 21" long and cut the three pieces from it if you have suitable size stock to do that with. It should be a safer bevel cut, and a definite if I were using the jointer to do it.

One could even use the T&G jointing method to do the entire thing as I showed with the 1953 PTWFE 10ER shaping method, and you are ready to glue it up once the bevels are in place. All in one operation, with no saw involved in the bevel. Easier at 45 though.

Everett