Page 2 of 2

Re: Tailstock vertical or not

Posted: Fri May 05, 2017 11:51 am

by wa2crk

If you can set up your drill press function as follows you can use almost any method to hold the blank. A drill press vise or any tooling that will hold the blank securely.

- wixie on the table.jpg (86.68 KiB) Viewed 4060 times

- wixie on the sawblade.jpg (81.46 KiB) Viewed 4060 times

The drill bit MUST be 90 deg to whatever support table is used to support the work.

Bill V

Re: Tailstock vertical or not

Posted: Fri May 05, 2017 1:48 pm

by rpd

I horizontal bore my pen blanks using the table and the miter gauge to align the blanks, this has the advantage that you can then swap the drill chuck for the sanding disk to square the ends of the blank. Someday I'll make a jig that slides in the miter slot, that will be even easier. Here is a link to the thread showing the setup.

http://shopsmith.com/ss_forum/viewtopic ... 69#p206969

Re: Tailstock vertical or not

Posted: Sun May 14, 2017 3:52 pm

by drl

I apologize for my slow response to you assistance--other projects have taken priority I think Ed's response probably is my answer and will be taken the next time I'm drilling pen blanks. I need to preload the flex in the tailstock when doing the alignment. I haven't been taking that into consideration. Doesn't take much when drilling pen blanks. Thanks to all.

Regards,

Dwight

Re: Tailstock vertical or not

Posted: Sun May 14, 2017 8:01 pm

by dusty

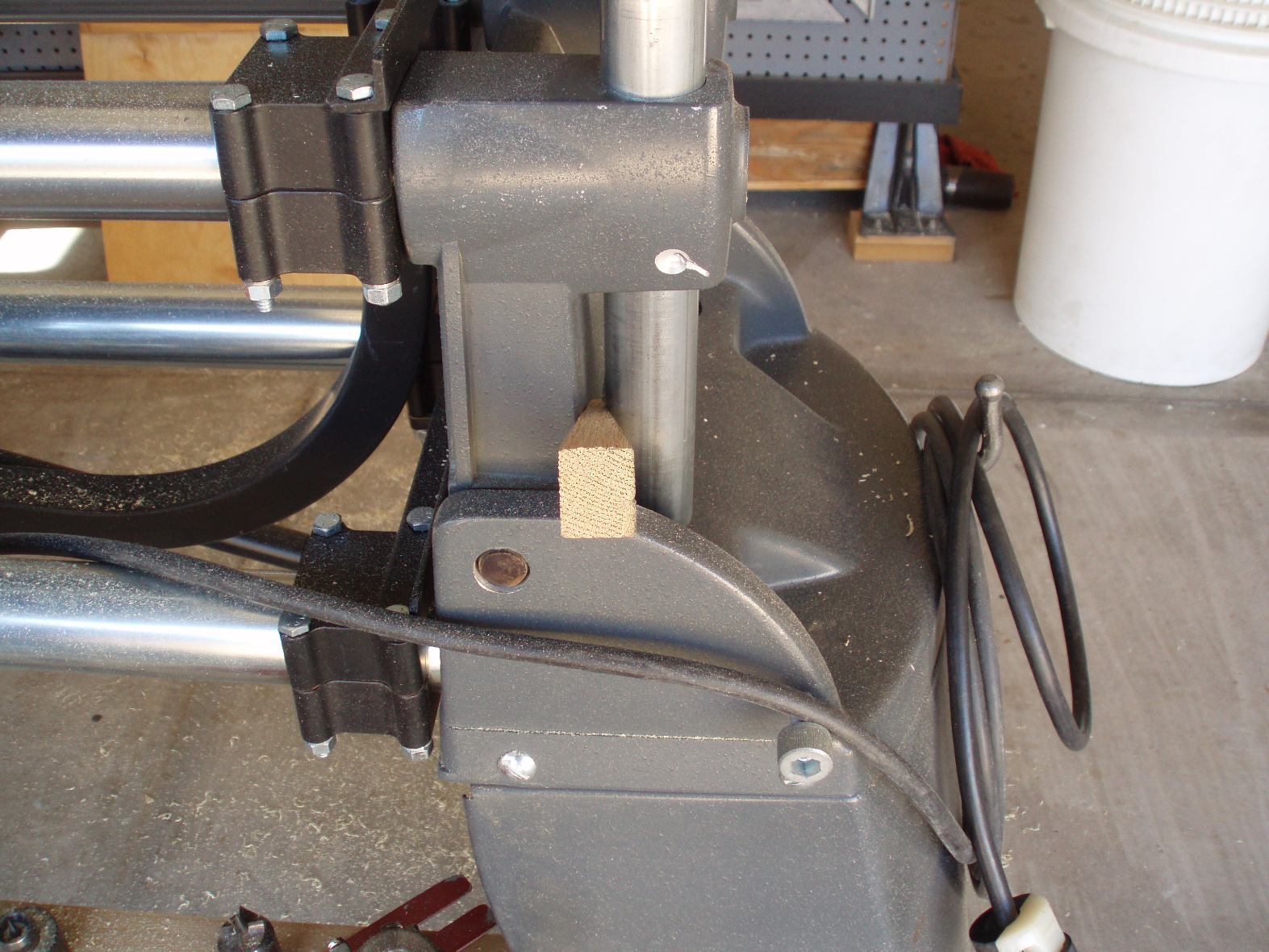

Pre-loading is undoubtedly the correct approach. Consider some form of this:

- P1250001.JPG (2.38 MiB) Viewed 3988 times

- P1250002.JPG (2.27 MiB) Viewed 3988 times

Shown here are the legs of an extension table but the principle is the same.

Re: Tailstock vertical or not

Posted: Mon May 15, 2017 10:03 am

by drl

Leave the wedges in during the drilling operation if I am understanding you correctly. I'll be giving that a try. Thanks.

Regards,

Dwight

Re: Tailstock vertical or not

Posted: Mon May 15, 2017 5:37 pm

by dusty

drl wrote:Leave the wedges in during the drilling operation if I am understanding you correctly. I'll be giving that a try. Thanks.

Regards,

Dwight

I don't make many configuration changes on the machine where I typically use the wedges but I leaver them in (most all of the time).