Page 2 of 3

Re: Shopsmith hacks

Posted: Wed Jul 08, 2020 7:30 am

by Gene Howe

Now, that's unique. Great idea.

Re: Shopsmith hacks

Posted: Thu Jul 09, 2020 2:51 pm

by edflorence

ryanbp01 wrote:I thought maybe it might be a fine time to devote a thread to the many adaptations people have made to their Shopsmiths in order to make woodworking easier.

BPR

When turning bowls, it can save a lot of sanding time if, once the bowl has been shaped using the main spindle, some light finishing cuts are made with the bowl turning in a reverse direction. This can be done even with a non-reversing headstock by fitting a toolrest to the left side and mounting the bowl on the upper auxilary spindle.

- and of course the wooden posts were turned on the shopsmith

- wooden-tool-rest-1.jpg (44.59 KiB) Viewed 15279 times

Re: Shopsmith hacks

Posted: Thu Jul 16, 2020 3:36 pm

by Busmanjoe

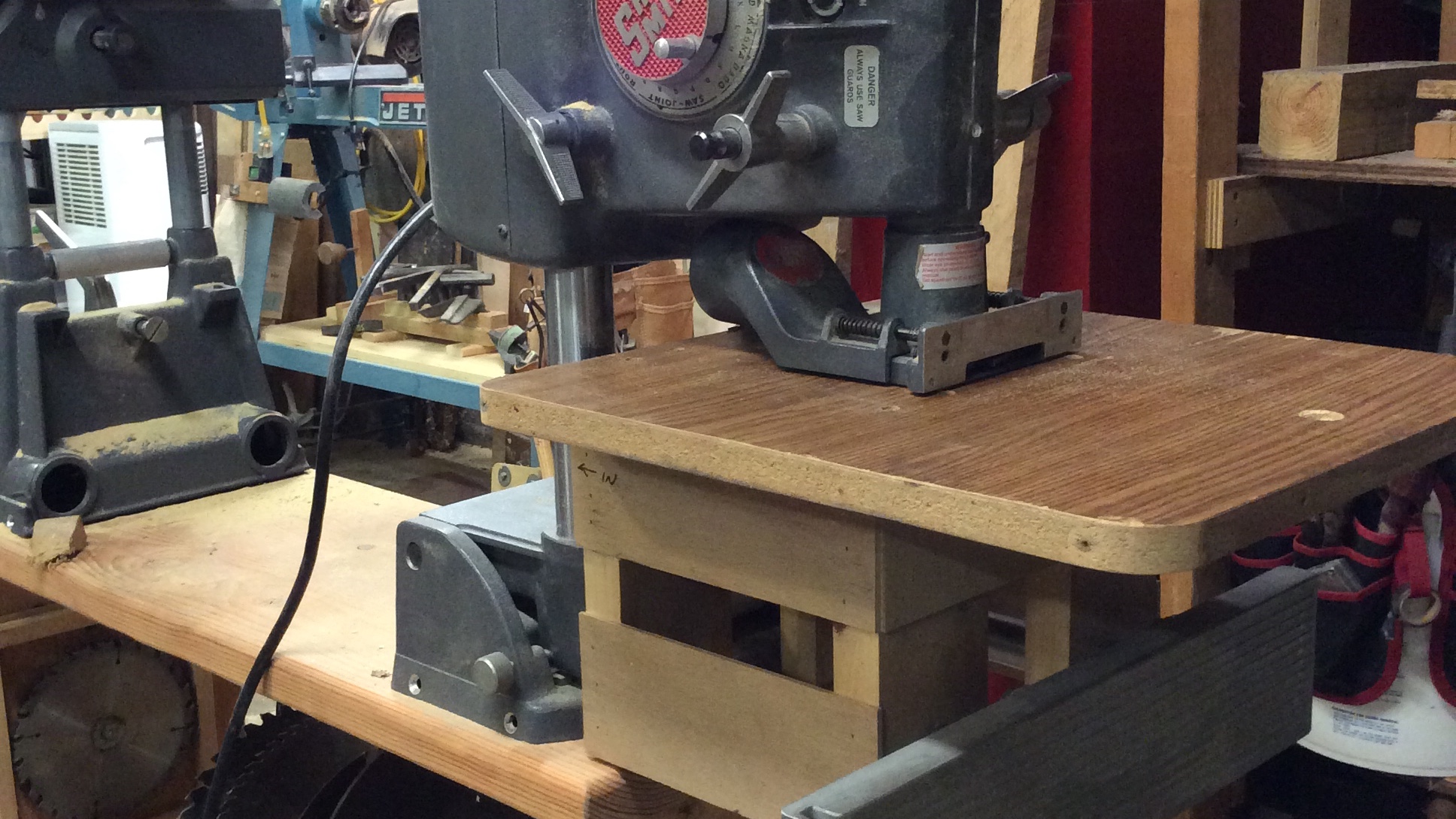

Shop Deputy biscuit joiner table

I use the biscuit joiner quite a bit so I made this table a while back out of an old entertainment center and other scrap.It mounts by sliding the extension through it and it stores underneath.only takes a minute to install it.It works great

Re: Shopsmith hacks

Posted: Thu Jul 16, 2020 9:20 pm

by JPG

If there ain't no picture, it does not exist!

Re: Shopsmith hacks

Posted: Wed Aug 12, 2020 4:05 pm

by easterngray

- CFE70B14-5E55-4F77-B584-85A05A6DA93C.jpeg (872.13 KiB) Viewed 14280 times

Re: Shopsmith hacks

Posted: Thu Aug 13, 2020 9:55 am

by rdgrnstd

Over the years I've made a lot of different jigs / add-ons for my Shopsmith. I'll see if I can list a few of the better ones.

Tail stock brace that's adjustable, left, right and back and forth.

After bending the quill shaft twice I built a way to convert the 5/8" shaft to 1" for turning large items.

Extending the live center and giving the tail stock support more support for large turnings.

Extending the live center past the end of the base to turn long pieces.

Drum sander, I saw on youtube.

beefing up the lathe armrest.

Sanding hood for sanding bowls

Lathe shield for flying chips

Steady rest for the lathe

Re: Shopsmith hacks

Posted: Thu Aug 13, 2020 1:21 pm

by JPG

Re: Shopsmith hacks

Posted: Thu Aug 13, 2020 3:02 pm

by edflorence

Wow!

Those are some very creative mods to the lathe.

The idea I have to share for a Shopsmith "hack" is much simpler, but it did work well for me.

A while back I was given some large (4-6 inches diameter) pieces of lilac. I decided that I would make most of it into turning blanks, but wanted to make small boards out of some of the clear sections. On line and in the magazines I have seen lots of clever and complex devices to hold small logs on the bandsaw for milling, but I wanted something simple, fast, inexpensive and that could be made with materials I had on hand. What I came up with is a tall fence and some clamps. Works great...it easily accommodates different lengths and diameters, is easy to make and easy to use.

- SS board slicer 1.jpg (323.95 KiB) Viewed 14207 times

- SS board slicer 2.jpg (330.23 KiB) Viewed 14207 times

- SS board slicer 3.jpg (263.01 KiB) Viewed 14207 times

Re: Shopsmith hacks

Posted: Sat Aug 15, 2020 3:16 pm

by wa2crk

I have a little something that I would like to add to this discussion. I call it the "Tweaker". I like to do segmented turning but sometimes the normal jigs o not work out as when in a feature ring and the pieces have to be cut with the piece in the vertical position.

I started by placing a piece of wood in the webbing under the main table. The piece has a "T" nut inserted on the table side. The hole in the block is for a 1/4 20 threaded rod.

- under table block.JPG (34.8 KiB) Viewed 13991 times

The rest of the system consists of a support block made to ride on the way tubes. This support holds a 3/4" dowel with an elongated 1/2" hole drilled through and captivated by two 3/4" conduit clamps. The threaded rod from the under table block has a 1/4- 20 connector bolt threaded onto it and extends from the table through the rotating dowel in the lower support.

- DSC04516.JPG (37.91 KiB) Viewed 13991 times

To install the system raise the table and move it to the right end of the machine and insert the 1/4 20 rod from the table through the dowel and through the base and lower the table until the base block rests on the way tubes and lock the table height lock. Then loosen the table tilt lock and and tilt the table to the approximate tilt angle. When the connector bolt is in contact with the dowel and the table tilt lock loose the table can be raised and lowered to adjust the tilt and then adjusted to the final angle that is desired. I put the fence on the table to add a bit of weight to take out any play and to have a place to put the Wixie. It will take about 3/4 of a turn of the connector bolt to change the angle by about .1 degree.

- good reading.JPG (27.54 KiB) Viewed 13991 times

- not a good reading.JPG (44.6 KiB) Viewed 13991 times

I used this gimmick to do my Christmas bowl completely on the Shopsmith

- side view.jpg (54.61 KiB) Viewed 13991 times

Hope someone can use this.

Bill V

Re: Shopsmith hacks

Posted: Sun Aug 16, 2020 8:49 pm

by Busmanjoe

- FF2FF40A-229F-44AC-B2D6-C007D246C6CF.jpeg (661.44 KiB) Viewed 13860 times

Pictures of Shop Deputy biscuit joiner table.It mounts using the extension table tubes