Page 2 of 10

Re: More On Disappointed In MiterSet

Posted: Sun Mar 07, 2021 1:13 pm

by JPG

Ed in Tampa wrote: ↑Sun Mar 07, 2021 9:31 am

Another way to do this is use a miter saw. A whole lot easier and you do not have to buy anything extra.

Yep the only 'extra' required is wishful thinking that is realized.

Re: More On Disappointed In MiterSet

Posted: Sun Mar 07, 2021 10:44 pm

by Cliffy

I made 3 different octagons today

I set the MiterSet very carefully after sanding the SS miter gauge wood face (that I made form oak) very flat one the jointer table.

I have sand paper on the wood face to stop movement along the face

I tried a second blade in the SS on one of the rings

They all came out exactly the same All 3 needed a little more acute angle We're looking at about a 1/16" opening on each side at the half point (4 segments in each half mating up )

All 3 have the same gap dimension between two halves of the octagon.

The same "mistake" is being repeated every time. Either me or the gauge Undetermined who as yet.

Tomorrow I will try shimming the pins again to see if I can get a perfect angle and repeat it.

Now I'm designing a "sled" to fasten to the SS table so I can bring the disc sander in to the work at the correct angle to just "kiss" the segments on each face to adjust the angle if I can't get the MiterSet to work.

The entire process of using the SS is so I could get rid of all the single use, bench top tools I had including a miter saw!

Re: More On Disappointed In MiterSet

Posted: Sun Mar 07, 2021 11:23 pm

by JPG

I see two other things affecting the outcome. We are already suspecting the angle created by the miterset.

Are you also verifying equal lengths of each segment?

Are you referencing the same edge for both end cuts?

Re: More On Disappointed In MiterSet

Posted: Mon Mar 08, 2021 6:36 am

by dusty

Cliffy you said in an earlier thread "When the miter gauge from my SS is inserted in the MiterSet slot there is a small amount of sideway play that will show up in segmented cuttings for bowls. Enough movement so perfect angles can't be set against a hard stop".

If your miter bar does not fit snugly in the MiterSet quit trying to make it work. To do so is futile. Resolve the issue with either MiterSet or with the miter bar.

I have to say that it sounds as though you are using a

standard MiterSet and not one made for use with a Shopsmith miter bar. I say this even though it has been stated that you have a "Shopsmith MiterSet".

Consider using a feeler gauge with the miter bar and MiterSet to determine just how much slop there is.

Quantify this issue, please.

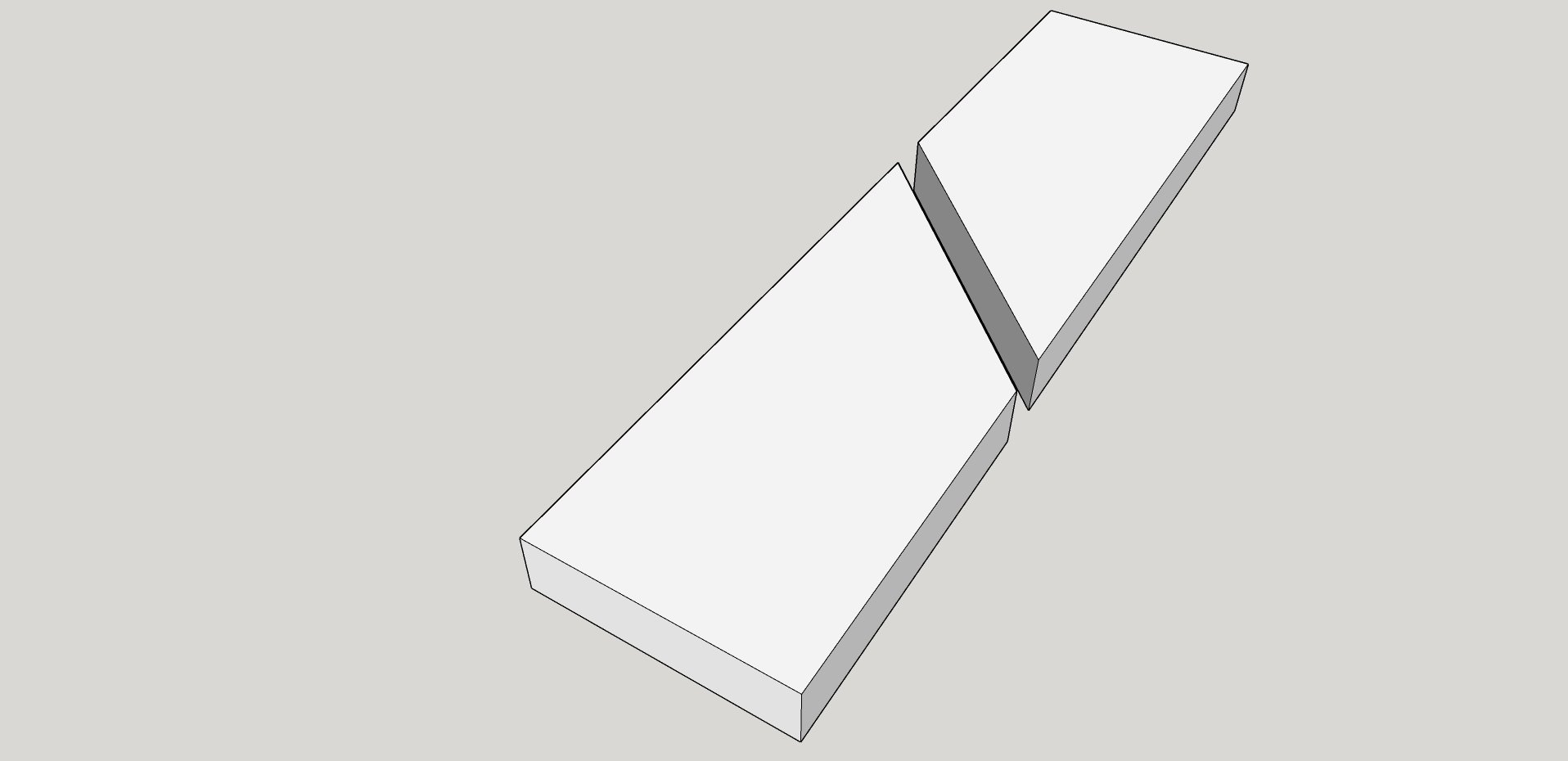

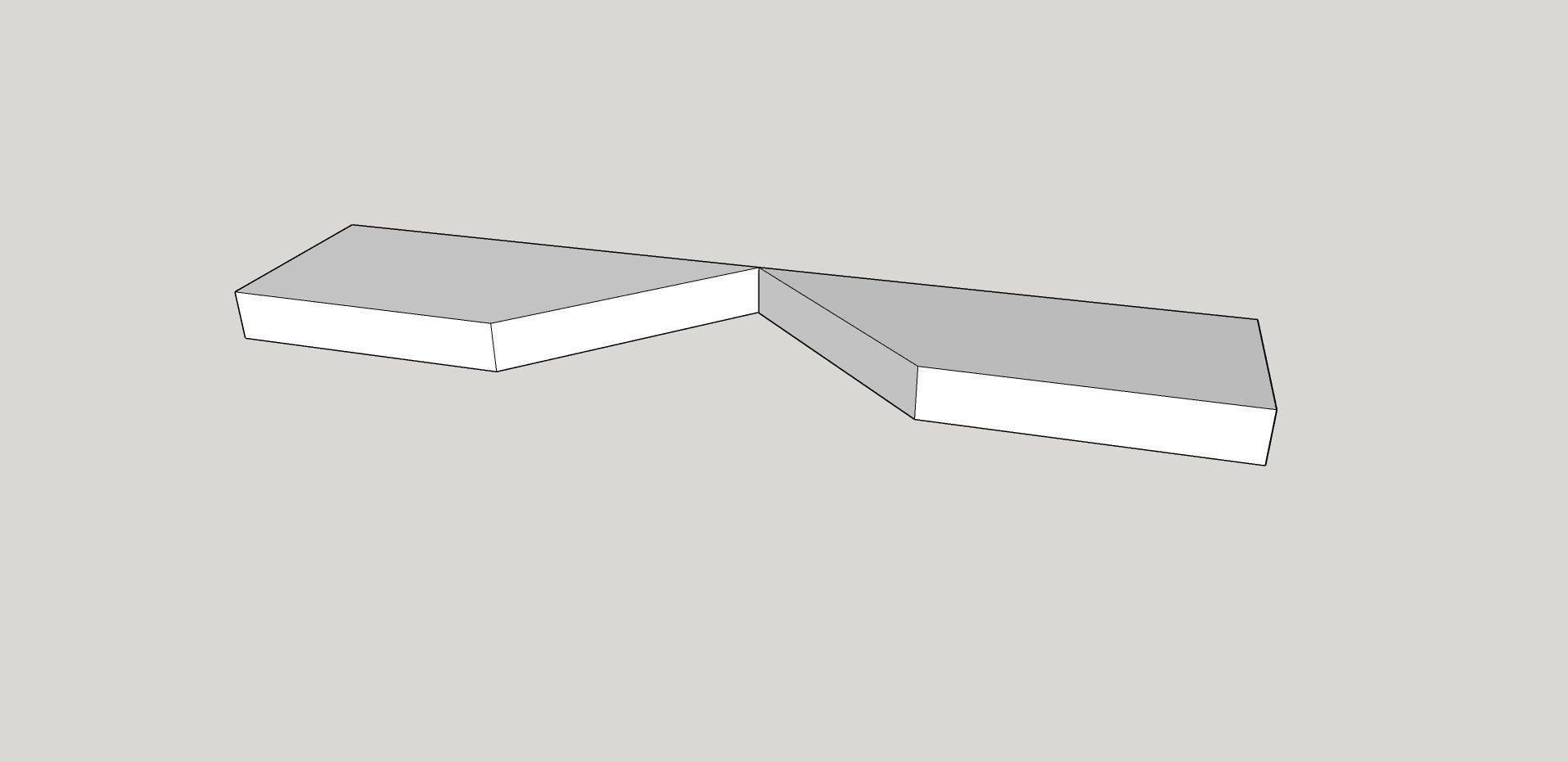

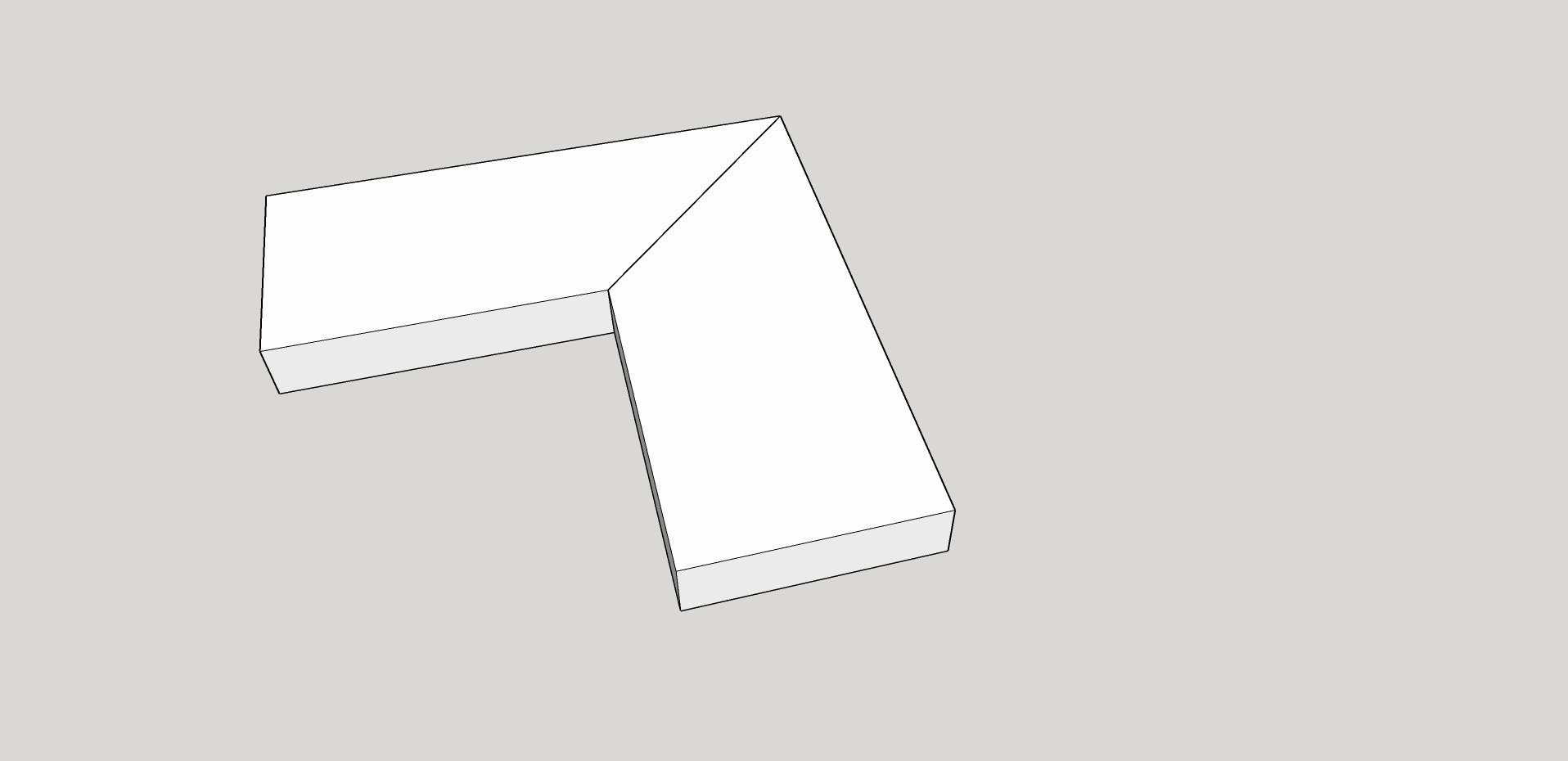

While we wait for pictures, could you do this without using the MiterSet. Use the miter gauge and whatever you would use to set it at 45 degrees.

The final fit (45.3) should be perfect and measure 90 degrees (both inside and outside). If it doesn't, the MiterSet won't help at all.

Now flip both pieces over and recheck joint for mismatch. Hopefully there are

none on either side.

- 45.jpg (54.99 KiB) Viewed 1468 times

- 45.2.jpg (48.19 KiB) Viewed 1468 times

- Perfect 90 degree corner???

- 45.3.jpg (48.15 KiB) Viewed 1468 times

Re: More On Disappointed In MiterSet

Posted: Mon Mar 08, 2021 12:31 pm

by chapmanruss

Cliffy,

Can you or have you already checked the angle on your miter after it has been set by using another tool like a protractor to verify the set angle. Also pictures would still help greatly. Can you measure the slot to see if it is the standard .753” wide miter slot or the Shopsmith version with a .723” slot. Dusty recommended checking the "slop" with a feeler gauge and if it has a .030" (if my math is correct) gap you have the standard version and not the Shopsmith version. I know after looking back at the previous thread some of this has already been covered but just reconfirming to be sure. One thing I didn't notice in the previous thread is checking the alignment of the table and fence. How are they?

Re: More On Disappointed In MiterSet

Posted: Mon Mar 08, 2021 3:33 pm

by adrianpglover

I didn't read through all of the first thread on this subject: but have you checked that your miter slots on your table are perfectly parallel to the blade? I do this by either using my Master Plate or a saw blade, along with a dial indicator attached to a bar in the miter slot. If this isn't parallel, then you could introduce error that you normally would miss when making rip or cross cuts. If you use the saw blade measurement technique make sure and measure it to the same tooth on the saw blade both at the front edge and the rear.

Re: More On Disappointed In MiterSet

Posted: Mon Mar 08, 2021 3:49 pm

by RFGuy

Actually very good points by Russ and Adrian. IF the table miter slot is not aligned to the sawblade then every cut will be off and thus throw off the segmented sections on assembly. Before using the MiterSet Segments, the assumption is near perfect table alignment has been achieved already. Also as Dusty points out it is still unclear on this thread whether there is side-to-side play when his miter bar is inserted into the MiterSet Segments.

Re: More On Disappointed In MiterSet

Posted: Mon Mar 08, 2021 5:23 pm

by Cliffy

I am back in the shop and will measure the slot in the MS with a feeler gauge As suggested

I am reading how to post pictures but PC work is not my specialty so I may need the 12 yr old next door to help me there :-)

I will measure the slot to blade angularity also today to see if they are parallel My good blade is a hollow ground Craftsman (new in box when I bought the SS) I also have a Freud carbide blade I can put in to check it with

Re: More On Disappointed In MiterSet

Posted: Mon Mar 08, 2021 5:42 pm

by Cliffy

OK The slot to bar gap measures .009 by feeler gauge

The bar mics at .724 using a Starett # 230 machinist's 1/10 mic

SO I have nine thousants gap with the bar in the MiterSet block

More later as I get the blade angularity issue checked

Re: More On Disappointed In MiterSet

Posted: Mon Mar 08, 2021 6:23 pm

by RFGuy

Cliffy wrote: ↑Mon Mar 08, 2021 5:42 pm

OK The slot to bar gap measures .009 by feeler gauge

The bar mics at .724 using a Starett # 230 machinist's 1/10 mic

SO I have nine thousants gap with the bar in the MiterSet block

More later as I get the blade angularity issue checked

I just measured mine to give you a comparison. Keep in mind, I haven't attempted to use mine yet so I can't say that mine works either, i.e. I haven't attempted a segmented woodturning with it yet. So, near the screw in the middle of the Shopsmith miter bar I get 0.003" gap using feeler gauges, but farther away from the screw I measure 0.006" gap. Is 0.009" the biggest or the smallest gap for your miter bar in the MiterSet Segments? You should have different size gaps depending on whether you measure near the miter bar screw or not.