Page 2 of 5

Re: Belt hitting way tube

Posted: Tue Dec 31, 2024 5:49 am

by RFGuy

I have cut a decent amount of 8/4 (2") cherry on my Mark V. To keep it from bogging down and to minimize burning, you need to make sure that belt is very tight. I am surprised how tight I have to set mine to keep it from slipping while cutting hardwoods, i.e. tighter than normally recommended belt guidance IMHO. Add to this a clean and sharp ripping blade and 8/4 cherry rips should be enjoyable. I use a Forrest Woodworker II 30 tooth ripping blade. I point out the clean blade because I have been surprised how big a difference it does make. A few times I was going to have my Woodworker II sharpened, but after a really good cleaning, it was cutting like brand new again so I haven't sharpened it yet.

Re: Belt hitting way tube

Posted: Tue Dec 31, 2024 8:18 am

by Melindacrosby

Thank you very much, I'll make that adjustment today. I never paid much mind until it came time to reassemble. I'll be following the suggestion for an actual ripping blade.

Re: Belt hitting way tube

Posted: Tue Dec 31, 2024 10:02 am

by Melindacrosby

RFGuy wrote: ↑Tue Dec 31, 2024 5:49 am

I have cut a decent amount of 8/4 (2") cherry on my Mark V. To keep it from bogging down and to minimize burning, you need to make sure that belt is very tight. I am surprised how tight I have to set mine to keep it from slipping while cutting hardwoods, i.e. tighter than normally recommended belt guidance IMHO. Add to this a clean and sharp ripping blade and 8/4 cherry rips should be enjoyable. I use a Forrest Woodworker II 30 tooth ripping blade. I point out the clean blade because I have been surprised how big a difference it does make. A few times I was going to have my Woodworker II sharpened, but after a really good cleaning, it was cutting like brand new again so I haven't sharpened it yet.

Thank you for the suggestion and reply RFguy. I just bought blade you suggested from SilverMills. Great reviews everywhere on it so thanks. My project is making cherry stair treads from 6/4 and 8/4 cherry. I had to join to make them 11" . Pushed my Mark V to its limit with planer as well. I learned some valuable lessons about my equipment and stock. Can't wait to get that blade on!

Mel

Re: Belt hitting way tube

Posted: Tue Dec 31, 2024 3:02 pm

by SteveMaryland

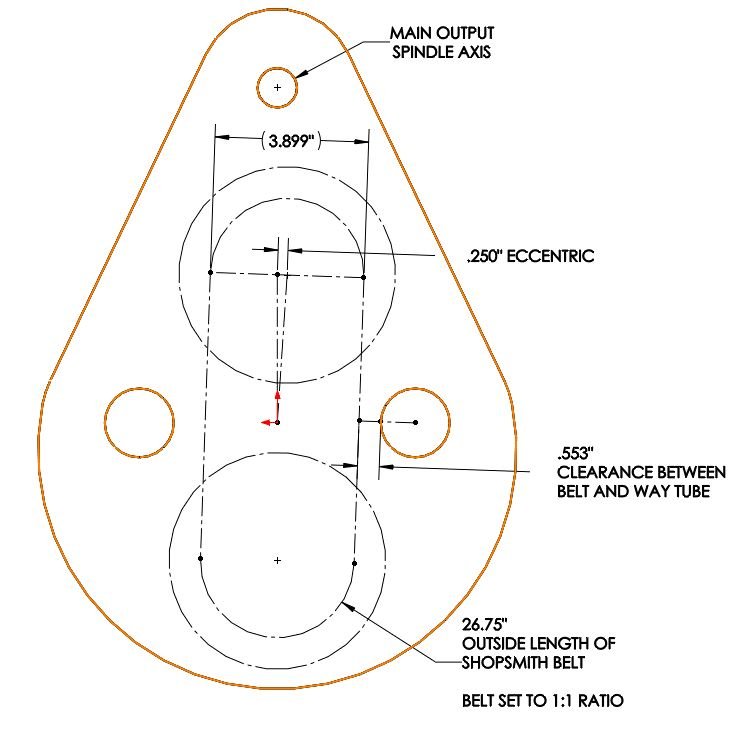

I still cannot see how, even in the worst case, that a Shopsmith Mark V drive belt could contact a way tube.

Even when the eccentric is set to the 3 or 9 o'clock positions, the closest the belt comes to the way tube is 1/2".

Could the motor mounting position be off?

Re: Belt hitting way tube

Posted: Tue Dec 31, 2024 4:41 pm

by DLB

SteveMaryland wrote: ↑Tue Dec 31, 2024 3:02 pm

I still cannot see how, even in the worst case, that a Shopsmith Mark V drive belt could contact a way tube.

Even when the eccentric is set to the 3 or 9 o'clock positions, the closest the belt comes to the way tube is 1/2".

Could the motor mounting position be off?

I agree, I'm sure that the engineers designed the machine so that in the worst case the drive belt would not contact the way tubes. My eccentric is positioned close to worst case, which I suspect is also pretty close to nominal, and I measured ~3/32" clearance. So the first difference I see between my machine and your model is I measured at speed "R" and you are modeling two speeds, very fast and very slow. So I measured again at the Slow stop and clearance was ~11/32". I have no reason to think "R" is the worst case speed for belt proximity to way tubes, but it is ~1/4" worse than Slow. My untested hypothesis is that worst case speed occurs when the belt is vertical, I think that is around "L".

Conclusions from that: 1) Speed matters, so real world worst case is different than the model shown. 2) Besides speed, there is an unexplained difference of about 5/32" between my machine and your model at Slow. 3) There is an unexplained difference of about 3/32" (or more) between my machine and the OP's machine.

- David

Re: Belt hitting way tube

Posted: Tue Dec 31, 2024 6:38 pm

by HopefulSSer

Melindacrosby -- where are you located? Perhaps there's a local SS owner who is more familiar with the machines and could look at it? I feel like this is one of those things that could be diagnosed in a few minutes in person....

Re: Belt hitting way tube

Posted: Wed Jan 01, 2025 3:06 am

by JPG

I think "vertical" is when the clearances are at a maximum from either waytube.

Re: Belt hitting way tube

Posted: Wed Jan 01, 2025 9:37 am

by dusty

Looking at your earlier images I am suspicious of your motor mounting location. If the sheaves are all properly positioned there is no way that the belt can contact the Ways.

Re: Belt hitting way tube

Posted: Wed Jan 01, 2025 1:08 pm

by SteveMaryland

Let's look at the belt position when the sheave ratio is 1:1 (the "mid-range" speed):

- DRIVE SHEAVE AND BELT PROXIMITY TO COMPONENTS (FROM POWER PLANT CAD MODEL) 3.JPG (57.1 KiB) Viewed 3929 times

The above layout shows the Shopsmith at the midrange speed + we have added the eccentric effect. Still looks like we have at least half an inch of clearance.

If the belt were too long, this would result in the belt coming closer to the way tubes - at all speeds. I think the OP's belt is stretched, plus the OP's pictures show the belt riding above the sheave OD. Those things, plus some slop in the motor mounting location - these might account for some of it. And maybe we are seeing evidence of some small (unintentional) unit-to-unit mfg variations in Mark V's over the years.

Re: Belt hitting way tube

Posted: Wed Jan 01, 2025 3:28 pm

by Melindacrosby

HopefulSSer wrote: ↑Tue Dec 31, 2024 6:38 pm

Melindacrosby -- where are you located? Perhaps there's a local SS owner who is more familiar with the machines and could look at it? I feel like this is one of those things that could be diagnosed in a few minutes in person....

I'm in Bristol Vermont.

I'm going to do make another adjustment of top belt and hope that does the trick. Ill show a picture of belt once last adjustment is made.