Page 2 of 3

Re: Upgrading a 500 (1985)

Posted: Mon Jun 09, 2025 5:23 pm

by franknsled

I appreciate the replies guys. Looks like I'll have to save some money. I wanted to upgrade to the 520 for the bigger table and extensions and better fence. I definitely have the 500 fence. Previous owner didn't have a guard of any kind. Not willing to do that. So I need the 520 table, extensions,

guards, arbor, and the support rails? Looks like I won't be using the table saw for a while.

Re: Upgrading a 500 (1985)

Posted: Mon Jun 09, 2025 7:09 pm

by HopefulSSer

I've got a my Grandad's greenie that I upgraded to 510 spec using parts from a 510 I bought cheap (then loaded up with the 500 parts and sold on, with appropriate disclaimers). The difference in tables is an absolute game-changer. With apologies to happy 500 owners, I'd never go back. The difference is massive (literally). I recently bought a 510->520 upgrade kit from SS -- not cheap. But the difference between the way the fence works is nearly as big a difference as the 500->510 upgrade.

Watch FB marketplace for an unloved 510. The one I bought came with a jointer, which I already didn't have. So I basically bought a jointer at market price and after selling the unwanted stuff on, I got a 510 upgrade free.

Before:

- IMG_8343 (1).jpeg (220.22 KiB) Viewed 531 times

After:

- IMG_8344.jpeg (230.29 KiB) Viewed 531 times

Re: Upgrading a 500 (1985)

Posted: Tue Jun 10, 2025 1:43 pm

by chapmanruss

Upgrading the Table System as HopefulSSer did above is a good way to go. As he said,

I upgraded to 510 spec using parts from a 510 I bought cheap

In the deal he added the Jointer to his collection. I would suggest checking craigslist too. You may even find a 520 used for just a bit more than a 510. This could be less expensive than a 510 being upgraded to a 520. Something to keep in mind is if you find a true 505 it is the same as the 510 but does not have the 2 Floating Tables, 4 Connector Tubes or the Adjustable Support Legs. Buying those separately can add a lot to the upgrade costs.

Another thing to know if buying a 510 that was made in the first year (1985) is they had a different way of attaching the Fence Rail Tubes. They are easy to distinguish from the later mounting of the Fence Rail Tubes. Below is an example of the early tube mounting.

_

- 510 floating table 1985 rail.jpg (40.73 KiB) Viewed 499 times

.

The holes are for attaching the tubes with screws and spacers. Later tubes do not have these holes and the threaded stud for mounting is permanently attached to the tube. It is why you will see references to when a 510 was made for upgrading to a 520.

Other pluses when buying a "complete" 510 or 520 is it may have other accessories specifically for those models, like Arbors, that you would otherwise have to buy separately.

Re: Upgrading a 500 (1985)

Posted: Tue Jun 10, 2025 11:12 pm

by franknsled

I'm about to dive into FB Marketplace and Craig's List

. This is on you guys!

Re: Upgrading a 500 (1985)

Posted: Wed Jun 11, 2025 2:21 pm

by chapmanruss

franknsled

WARNING: collecting Shopsmith Tools can be habit forming.

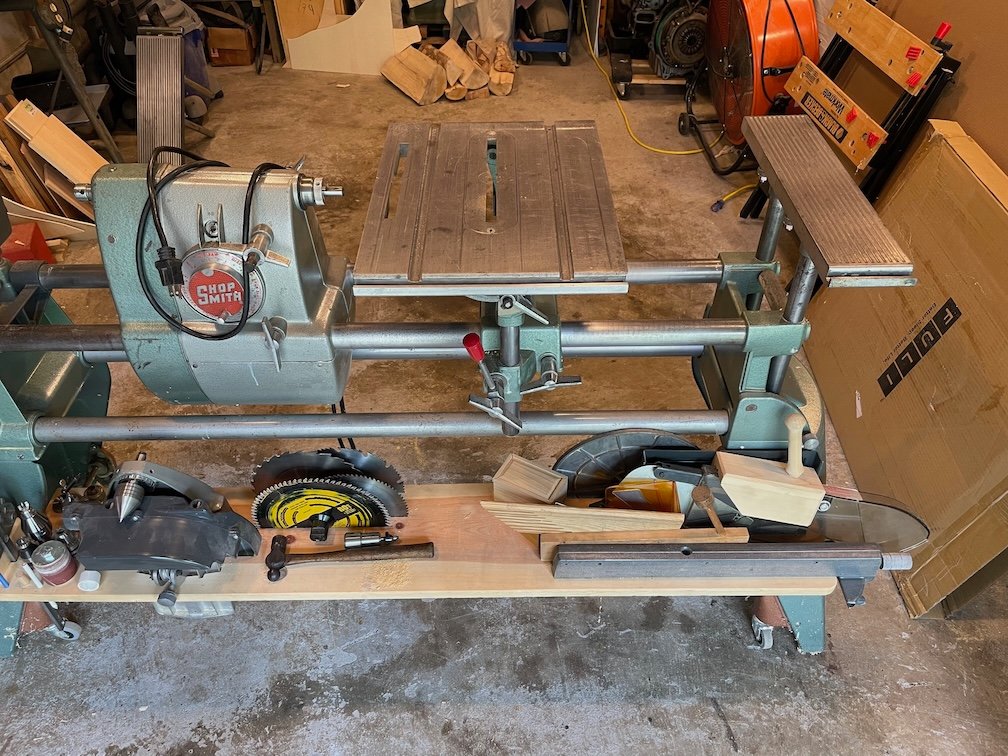

The picture below was taken almost two years ago on moving day for the Shopsmith's in our new location.

_

- moving day 2023.JPG (257.8 KiB) Viewed 341 times

.

Not everything can be seen in this picture.

Re: Upgrading a 500 (1985)

Posted: Wed Jun 11, 2025 9:05 pm

by JPG

chapmanruss wrote: ↑Tue Jun 10, 2025 1:43 pm

Upgrading the Table System as HopefulSSer did above is a good way to go. As he said,

I upgraded to 510 spec using parts from a 510 I bought cheap

In the deal he added the Jointer to his collection. I would suggest checking craigslist too. You may even find a 520 used for just a bit more than a 510. This could be less expensive than a 510 being upgraded to a 520. Something to keep in mind is if you find a true 505 it is the same as the 510 but does not have the 2 Floating Tables, 4 Connector Tubes or the Adjustable Support Legs. Buying those separately can add a lot to the upgrade costs.

Another thing to know if buying a 510 that was made in the first year (1985) is they had a different way of attaching the Fence Rail Tubes. They are easy to distinguish from the later mounting of the Fence Rail Tubes. Below is an example of the early tube mounting.

_

510 floating table 1985 rail.jpg

.

The holes are for attaching the tubes with screws and spacers. Later tubes do not have these holes and the threaded stud for mounting is permanently attached to the tube. It is why you will see references to when a 510 was made for upgrading to a 520.

Other pluses when buying a "complete" 510 or 520 is it may have other accessories specifically for those models, like Arbors, that you would otherwise have to buy separately.

What's with the center hole?

Re: Upgrading a 500 (1985)

Posted: Wed Jun 11, 2025 9:15 pm

by jsburger

JPG wrote: ↑Wed Jun 11, 2025 9:05 pm

What's with the center hole?

The stud/knob to tighten the connector tubes.

Re: Upgrading a 500 (1985)

Posted: Thu Jun 12, 2025 12:30 pm

by JPG

jsburger wrote: ↑Wed Jun 11, 2025 9:15 pm

JPG wrote: ↑Wed Jun 11, 2025 9:05 pm

What's with the center hole?

The stud/knob to tighten the connector tubes.

On the FRONT? side? The jackscrews are on the back side(smooth bore) and the table has a tapped hole.

Re: Upgrading a 500 (1985)

Posted: Thu Jun 12, 2025 1:01 pm

by chapmanruss

I don't know why the holes where the Connector Tube Locks go are through the front of the tube too. All the 510/505 Tables I have had are later ones. An early Main Table example is below.

_

- Not a Mark V I have owned

- Mark V 510 early tube Durham OR.jpg (159.02 KiB) Viewed 266 times

.

JPG, if I remember correctly, I first learned about the difference in the first year 510/505 Fence Rail Tubes from you.

Re: Upgrading a 500 (1985)

Posted: Thu Jun 12, 2025 1:48 pm

by JPG

Whoops!!!!

Oh how quickly we forget when not actively using something recently.

So I conclude(upon careful current examination of a main table rail that is not presently connected to a table) that all hole producing machining is done with a single setup from the tube outer front surface. That includes not only the smooth bore drilling, but also counter sinking the mounting bolt holes.

I note that this particular tube has very rough counter sink machining(chatter). That cannot help but add to the alignment issues. That counter sink is on the interior back side.