Page 3 of 3

Re: Powering other tools with a Shopsmith

Posted: Mon Sep 28, 2020 4:29 pm

by edma194

And the plot thickens...

I ended up getting headstock #159532 after the seller dropped the price and threw in a pair of like new legs, base castings, and the cleanest set of casters I have ever seen. It's only a single bearing quill but should be fine for powering a bandsaw. Or it would be fine for a spare or spare parts. But I'm going to look at mounting this in the bandsaw cabinet, if it fits in easily enough then it will be the solution because it's time to move on this, I want to get my bandsaw running.

Now I have to figure out which machine deserves the pristine legs and casters, probably do a lot of shuffling of parts around. But I never have to use the worst caster parts now. It also came with a 500 main table top, I even have ideas for that.

Re: Powering other tools with a Shopsmith

Posted: Sat Dec 19, 2020 4:53 pm

by edma194

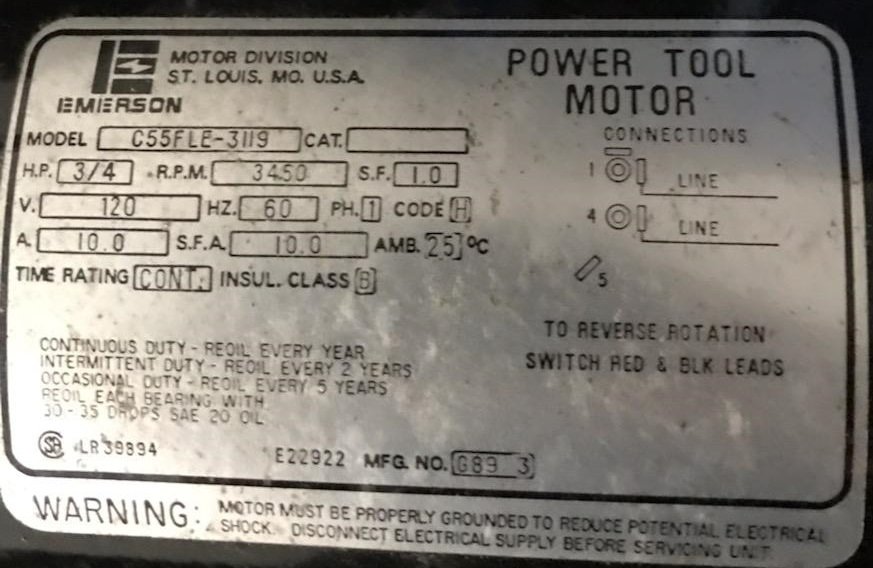

Been working on getting that headstock into the stand I have for the Delta Bandsaw, but then today I found a Power Station in very good condition, with nice clean casters too. The 3/4 HP motor is plenty for the bandsaw. The bandsaw shaft will be slightly higher than the Power Station shaft, but the whole speed control box on the Power Station can be raised up to match. It would be interesting to try to mount the bandsaw using the short tubes on the Power Station but I'm not sure that would work well and I'll probably mount it on some sort of custom carriage plate.

Interestingly, according to the motor nameplate it would be easy to add a switch to reverse that motor if someone needed that capability.

And I picked up a Strip Sander along with it just to help round out the collection.

- power station motor.jpg (81.82 KiB) Viewed 1296 times

Re: Powering other tools with a Shopsmith

Posted: Sat Dec 19, 2020 5:07 pm

by JPG

I do not understand the bandsaw input shaft higher than the Power station shaft. Ya gots collars on the mount?

Re: Powering other tools with a Shopsmith

Posted: Sat Dec 19, 2020 6:04 pm

by jsburger

JPG wrote: ↑Sat Dec 19, 2020 5:07 pm

I do not understand the bandsaw input shaft higher than the Power station shaft. Ya gots collars on the mount?

He said it is a Delta band saw. Not sure how that would mount on the Power Station. It seems to me now that the OP has a Power Station it would be better to sell the Delta and buy a SS band saw.

Re: Powering other tools with a Shopsmith

Posted: Sat Dec 19, 2020 6:22 pm

by JPG

Oh yeah! Missed that.

Takes more than 'raising' the 'speed control box'. The stuff underneath as well(or get different size belts).

Re: Powering other tools with a Shopsmith

Posted: Sat Dec 19, 2020 6:54 pm

by edma194

JPG wrote: ↑Sat Dec 19, 2020 5:07 pm

I do not understand the bandsaw input shaft higher than the Power station shaft. Ya gots collars on the mount?

It's a Delta 14" bandsaw, not a Shopsmith bandsaw. I have extra extension tables, I am still considering mounting the bandsaw on one of those and then mounting it in the Power Station carriage, but that might have problems. It will certainly raise the bandsaw up higher. I have to take careful measurements, this bandsaw has a cast iron frame and is very heavy, and then altogether the weight of it would have to be centered over the extension table legs, and then not interfere with the tall mounts on the Power Station carriage. Perhaps mounting on an extension table is still feasible, but it seem more likely I will mount the bandsaw on plywood or metal plate that will replace the Power Station carriage.

On top of that have to stiffen the Power Station base under the speed changer box according to another thread somewhere on the forum. I'll replace all the belts using links and check alignments carefully trying to eliminate noise and vibration.

Re: Powering other tools with a Shopsmith

Posted: Sat Dec 19, 2020 6:58 pm

by edma194

jsburger wrote: ↑Sat Dec 19, 2020 6:04 pm It seems to me now that the OP has a Power Station it would be better to sell the Delta and buy a SS band saw.

I already have 3 SS bandsaws. I want to use this monster because I can add an extension block and resaw up to 12", and it's 73 years old. I love old tools. I love old tools so much a lot of people even call me an old tool. I think that's why anyway, not positive about that.

Re: Powering other tools with a Shopsmith

Posted: Sat Dec 19, 2020 7:27 pm

by jsburger

edma194 wrote: ↑Sat Dec 19, 2020 6:58 pm

jsburger wrote: ↑Sat Dec 19, 2020 6:04 pm It seems to me now that the OP has a Power Station it would be better to sell the Delta and buy a SS band saw.

I already have 3 SS bandsaws. I want to use this monster because I can add an extension block and resaw up to 12", and it's 73 years old. I love old tools. I love old tools so much a lot of people even call me an old tool. I think that's why anyway, not positive about that.

OK. I have a Powermatic 14" band saw with a 6" riser block. It is on it's own PM stand with motor. I would never consider mounting it on my SS Power Station. I also have a SS band saw mounted on a power stand (not the Power Station). I use them both all the time. The PM has a 3/4" blade on it most of the time for resawing and the SS has narrower blades for curved work.

If it was me I would use one of your SS band saws on the Power Station and just build a stand for the Delta and power it with a cheap and simple 3/4HP motor.

Just my opinion. Good luck with the Delta on the Power Station.

Re: Powering other tools with a Shopsmith

Posted: Sun Dec 20, 2020 4:39 pm

by edma194

You guys need more sense of adventure! I want variable speed on all my tools now. I don't want move belts to change speed ever again. Well, unless that really is not the most practical approach. I'm perfectly prepared to put this on the stand I have from a broken parts machine and use one of several motors collecting dust on the shelf.

I'm finding some things about the Power Station.

This article talks about improvements to the carriage to distribute weight better and reduce vibrations. It also links to the forum thread by BuckeyeDennis about reinforcing the base under the speed changer. Mine doesn't look like an upgraded version. If the base is vibrating I think it needs a lot more stiffening overall.

Mine seemed overly noisy even after reading about the noise complaints. Not surprising because the set screw wasn't secured on the top pulley and it was moving on the shaft and the key was loose. Tightening that up made a huge difference but I'm sure the belts could be better aligned and tensioned.

Have to play with it some more, the upper shaft seems stable, it's the variator shaft and adjustment mechanism that worry me. Once a speed is selected they have to lock down tight. Not sure how well that lock on the end of the adjustment shaft is doing that.

The Power Station is nice and clean, the Strip Sander not so much. A reminder to everyone putting your tools away in storage, dust collector ports looks like a Vacancy sign to mice. They may find a way through any opening eventually but no need to advertise it an express route.

Re: Powering other tools with a Shopsmith

Posted: Sun Dec 20, 2020 8:44 pm

by JPG

The variator slides are quite sloppy.

Belt dressing will help reduce the belt set caused rattling.