Page 3 of 12

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 9:42 am

by shipwright

The spring is not weak.

By “fully wound” I just meant that I had loaded the spring before installing the quill.

I don’t think it’s the spring. It is hard(ish) to push together and pull apart in my hands. I can feel the pressure and vacuum suction.

It’s weird.

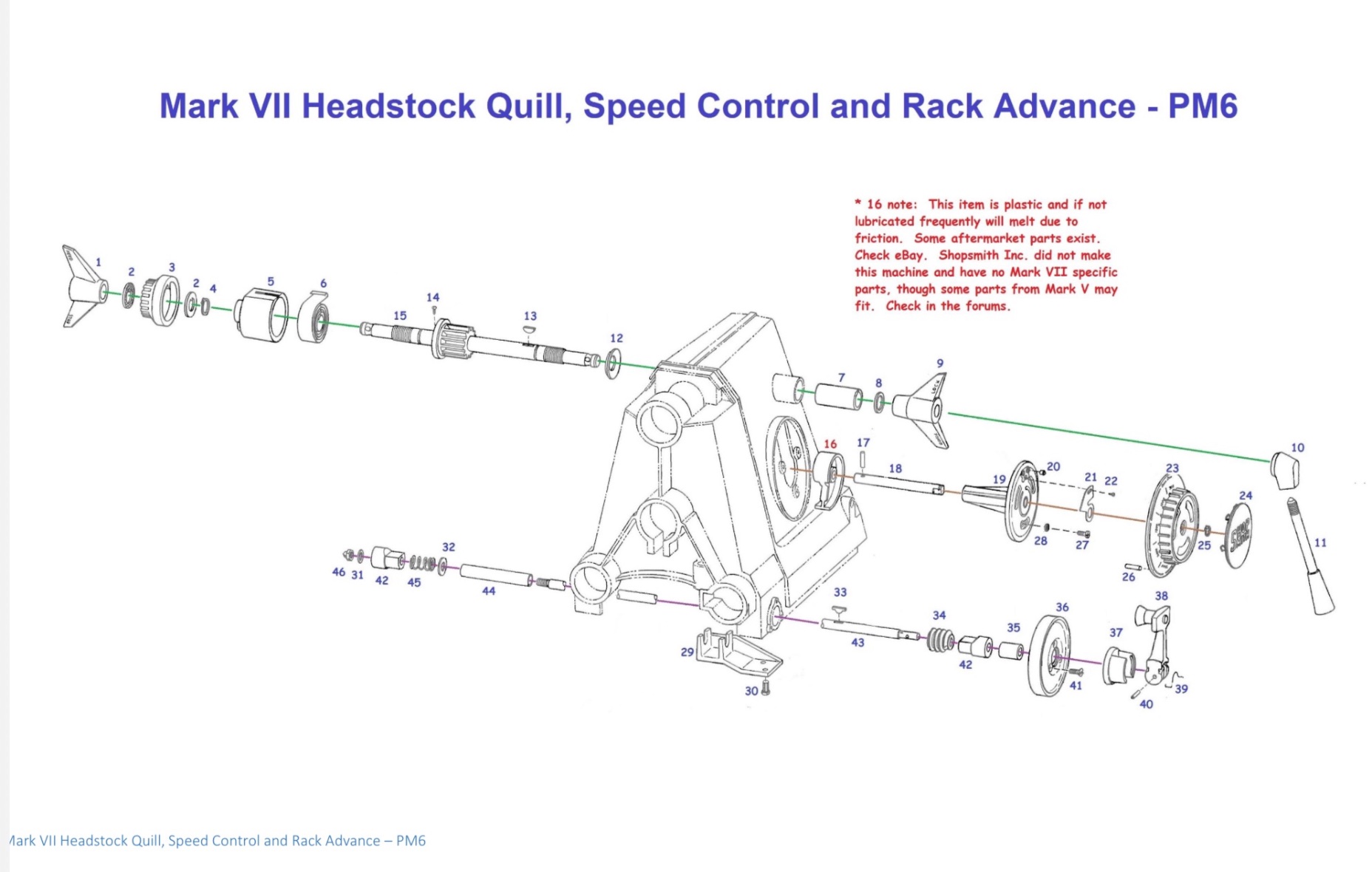

Do you think drilling a couple of small holes in the plastic spline receiver would significantly weaken it? Is it a Mark V part that I can replace?

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 12:10 pm

by JPG

I think one small hole(<1/16") will prove the theory and not diminish strength. I believe compatible with all other versions of the nylon coupler.

Question is where?

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 12:36 pm

by shipwright

That’s a relief. Today I’m going to try the quill return without the main shaft in place to make sure it isn’t friction in the sliding area of the quill. If it isn’t that I’ll try a small hole and see if that helps. I’ll also try some dry lube spray.

Wish me luck.

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 12:40 pm

by shipwright

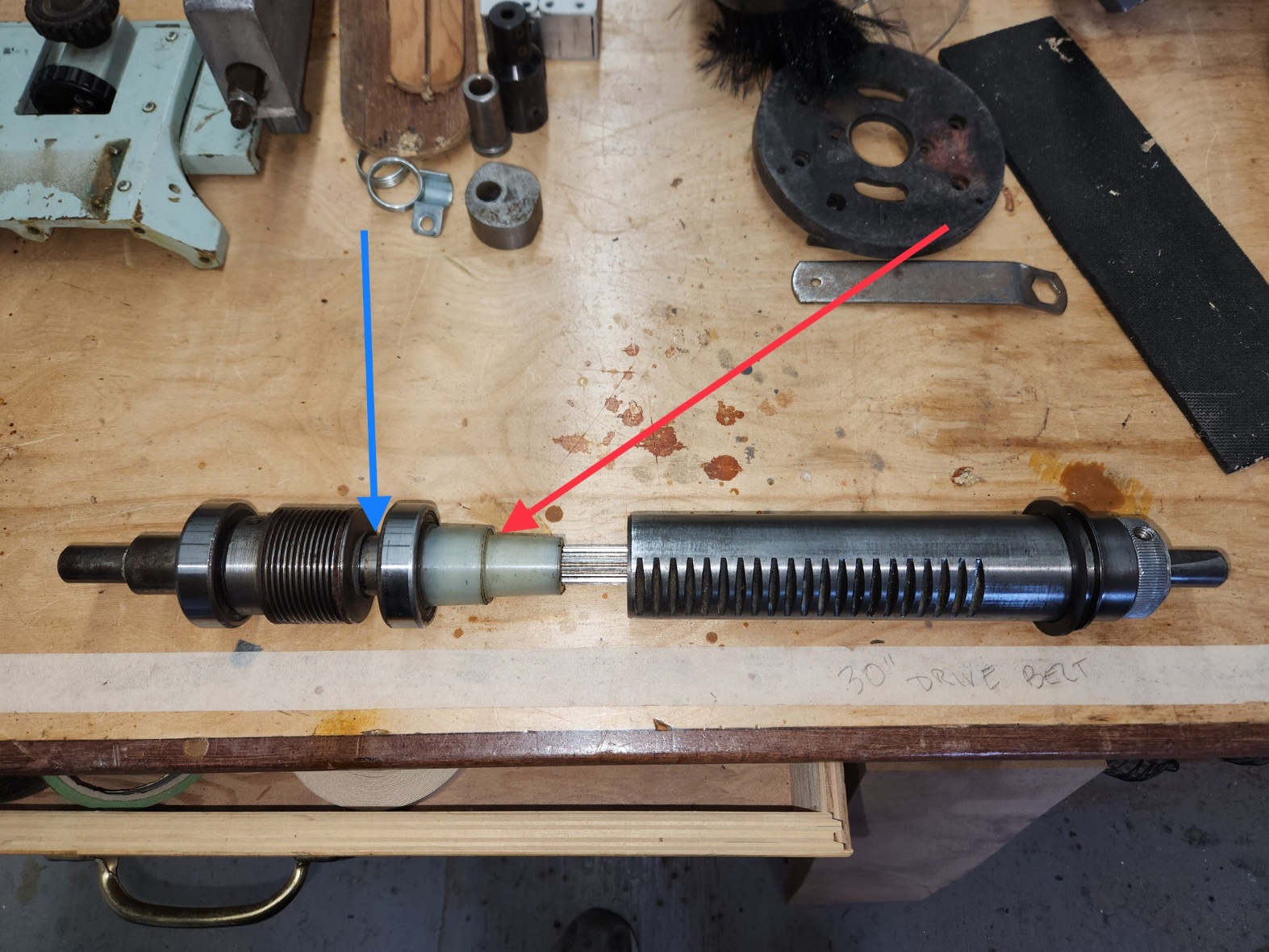

I’m thinking about the red arrow for the first try. What do you think of trying where the blue arrow is?

- 20231003_155655_Original.jpeg (596.4 KiB) Viewed 1010 times

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 9:33 pm

by JPG

Blue, no. If it is the coupler that is creating the 'vacuum' the red location is more likely to succeed. That is as long as it coincides with the transition between quill spline and drive sleeve spline.

How some ever, the trapped air is likely in the drive sleeve. But the splines should allow air to escape.

I think we need to be sure just where the trapped air is.

But like you said it may be spline drag.

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 9:57 pm

by shipwright

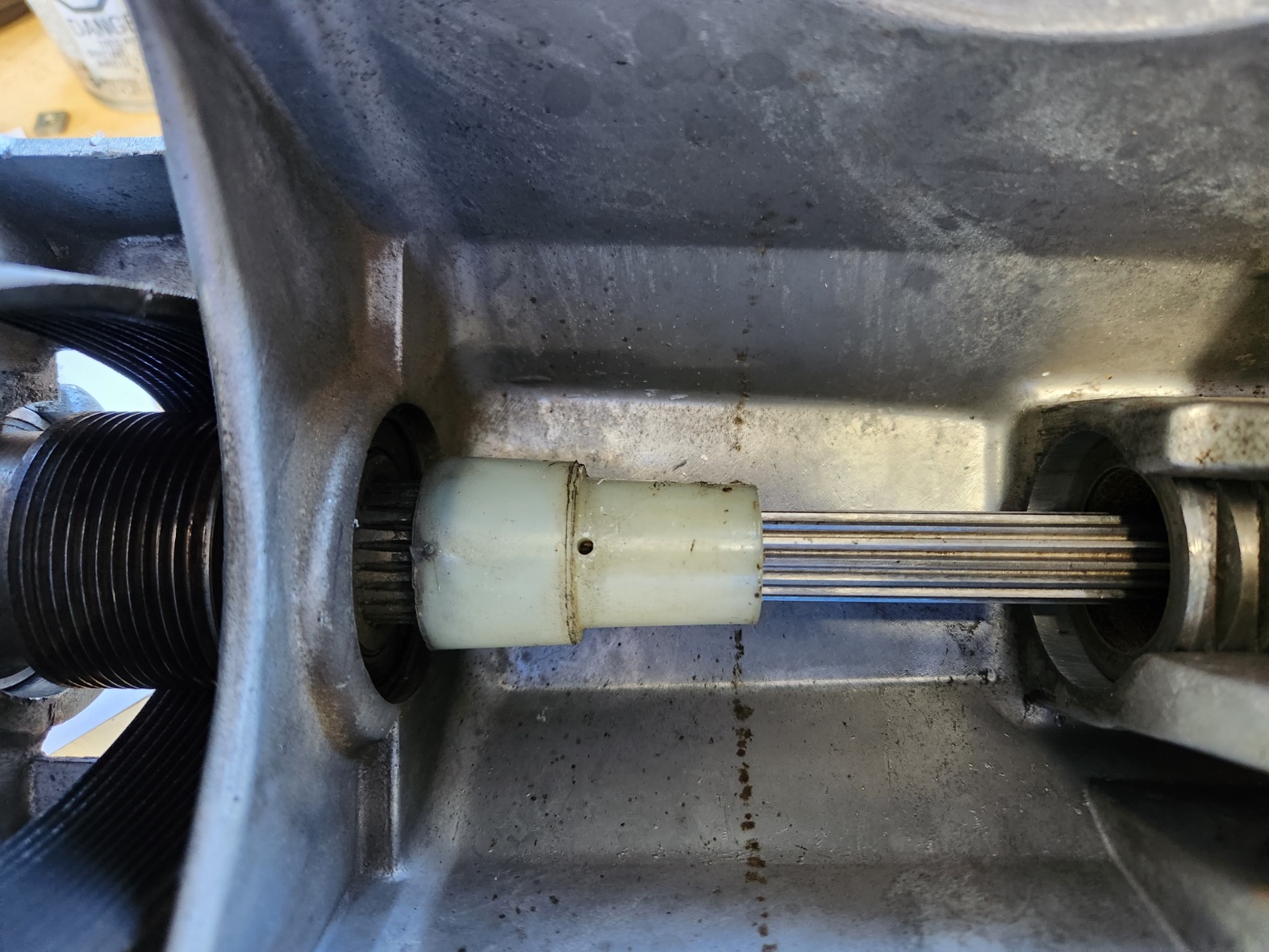

I cleaned a dry lubed everything and drilled one 7/64” hole in the coupler. I also flipped the cupped washer in the quill feed. (The diagram in the manual disagrees with you about that) it moved a little better but still did not retract well. I decided to move on and finally got it running. With the vibration of the motor running, or the rotation of the shafts perhaps, it retracted just fine. I didn’t get much time to play with it as it was the end of the day but tomorrow I should be able to clean up the details and have a better picture of what I have.

- 20231004_102957_Original.jpeg (521.21 KiB) Viewed 980 times

- IMG_3140.jpeg (234.06 KiB) Viewed 980 times

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 10:11 pm

by JPG

Yes I was influenced by the M5 positioning of the cup washer. Thank You for catching that! That shifts the quill shaft out towards the stop end.

I do question it's accuracy as the cupped washer provides the transition between the sliding sleeve and the web.

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 10:14 pm

by shipwright

To be honest I don’t think it made any difference but who knows.

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 10:24 pm

by JPG

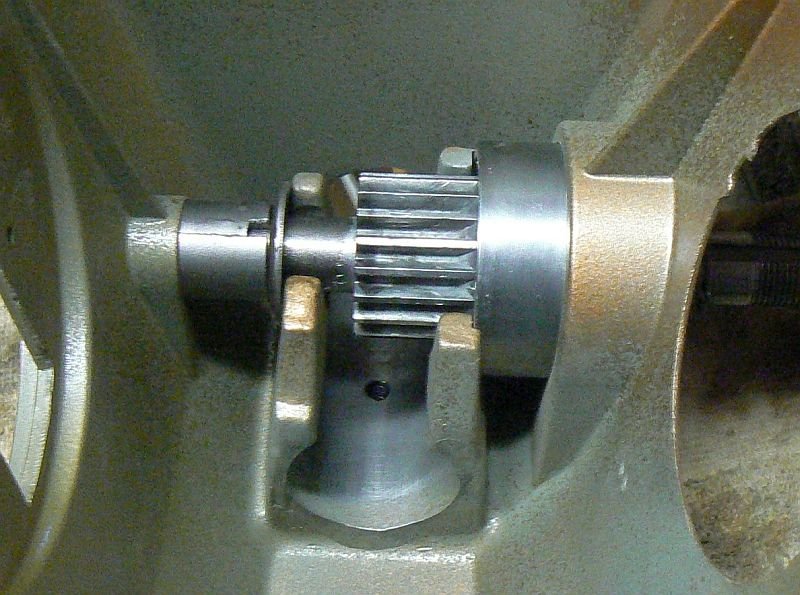

- mvii quill.jpg (104.81 KiB) Viewed 961 times

Gotta say 'my way' makes more sense.

Re: Mark VII “Project Machine”

Posted: Wed Oct 04, 2023 10:27 pm

by shipwright

I can’t disagree but I thought if I was looking for a problem I should try the “book version”.

Like I said, doesn’t seem to make any difference.