Page 5 of 6

Re: Table flatness

Posted: Wed Jan 04, 2023 12:23 pm

by RFGuy

dusty wrote: ↑Wed Jan 04, 2023 11:05 am

I guess you're just stuck with what you got. The remaining solution is to be satisfied with what ever precision you can achieve.

Besides that -

the stated measurements all through this thread are probable an order of magnitude better than the woodworking produced by any/all of us.

Dusty,

I have to disagree with this. IF a major tablesaw manufacturer requires their table flatness to be under 0.010" (as I reported here:

viewtopic.php?p=304921#p304921) and David & HopefulSSer are seeing 0.030" (3x higher), then I have to believe this will impact one's ability to achieve a square cut for ANY application. For sure it would impact segmented bowl turning as the 0.25° error would be substantial, but likely would impact other woodworking projects as well.

IF you deem a dip of 0.030" near the blade to be insignificant for cuts in your workshop, then can you tell us how much of a dip would concern you? At what level does flatness deviation affect the quality of a tablesaw cut???

Re: Table flatness

Posted: Wed Jan 04, 2023 1:23 pm

by dusty

RFGuy wrote: ↑Wed Jan 04, 2023 12:23 pm

dusty wrote: ↑Wed Jan 04, 2023 11:05 am

I guess you're just stuck with what you got. The remaining solution is to be satisfied with what ever precision you can achieve.

Besides that -

the stated measurements all through this thread are probable an order of magnitude better than the woodworking produced by any/all of us.

Dusty,

I have to disagree with this. IF a major tablesaw manufacturer requires their table flatness to be under 0.010" (as I reported here:

viewtopic.php?p=304921#p304921) and David & HopefulSSer are seeing 0.030" (3x higher), then I have to believe this will impact one's ability to achieve a square cut for ANY application. For sure it would impact segmented bowl turning as the 0.25° error would be substantial, but likely would impact other woodworking projects as well.

IF you deem a dip of 0.030" near the blade to be insignificant for cuts in your workshop, then can you tell us how much of a dip would concern you? At what level does flatness deviation affect the quality of a tablesaw cut???

No, I can not tell you that. All I can tell you is what I have experienced and what I believe. I have occasion to work with and on four different Shopsmith table saws and all of them have tables that "are not flat". Since I have never had inaccurate cuts that I believe were caused by this lack of flatness I stand by my position.

This none of this bickering about what I believe helps the OP at all - I'll not comment again on this thread

Re: Table flatness

Posted: Wed Jan 04, 2023 1:27 pm

by RFGuy

dusty wrote: ↑Wed Jan 04, 2023 1:23 pm

No, I can not tell you that. All I can tell you is what I have experienced and what I believe. I have occasion to work with and on four different Shopsmith table saws and all of them have tables that "are not flat". Since I have never had inaccurate cuts that I believe were caused by this lack of flatness I stand by my position.

This none of this bickering about what I believe helps the OP at all - I'll not comment again on this thread

Dusty,

Thanks. I am just trying to figure out at what point should one worry about this? I agree that many of us have only a small deviation in flatness of our main tables and this would likely never affect the quality of a cut (to the level that one needs in woodworking). However, I am wondering when should we worry? It seems like David & HopefulSSer found a significant dip in their main tables that I think

could impact that quality of cut.

I don't have the answer to this question...just asking out of curiosity.

Re: Table flatness

Posted: Wed Jan 04, 2023 5:18 pm

by DLB

RFGuy wrote: ↑Wed Jan 04, 2023 1:27 pm

Thanks. I am just trying to figure out at what point should one worry about this? I agree that many of us have only a small deviation in flatness of our main tables and this would likely never affect the quality of a cut (to the level that one needs in woodworking). However, I am wondering when should we worry? It seems like David & HopefulSSer found a significant dip in their main tables that I think

could impact that quality of cut.

I don't have the answer to this question...just asking out of curiosity.

From my perspective, it depends on both magnitude and location. For example, the problem on mine was large but as far as I can tell was isolated to the left side of the blade. The 520 was new to me and I was following the book alignment procedure. Putting the miter gauge in the left slot to align the rip fence was a nogo, the miter gauge would not travel properly through the dish in the table surface. But if I had worked around that and aligned the fence some other way I could have done all kinds of operations accurately referencing the table to the right of the blade and using the right miter slot. At the same time, the left miter slot would have been as useless for anything else as it was for aligning the rip fence.

The OP observed a different alignment issue, and it is a great observation. We know that ideally the axis of rotation is normal (perpendicular in all directions) to the table for drill press and similar operations. But both the MGD and Sawdust Sessions methods for shimming rely on measured or gauged distance from plane of rotation to table. To me, this is a potential problem even if the table is flat with 0.010". If those deviations from flat happen to be in the area you need to measure, this is going to translate to an error.

That said, I like the 0.010" threshold, in the interests of having a number.

- David

Re: Table flatness

Posted: Wed Jan 04, 2023 5:27 pm

by HopefulSSer

dusty wrote: ↑Wed Jan 04, 2023 7:41 am

Should have said this earlier BUT I doubt that your sanding disks are "flat" though they might be "good enough" to use for this purpose.

The trick of Scott's technique is that it really doesn't matter how flat the sanding disk is because you're always measuring from the

same spot on it. No different from setting the rip fence by measuring from the same tooth on the saw blade.

Re: Table flatness

Posted: Wed Jan 04, 2023 5:54 pm

by reible

I had a little time this afternoon so I went out to the shopsmith drill press and took a look at the table for flatness.

First off the largest "dip" I could find was not centered of the table or where the drill press center is. So it is unlikely that any distortion has been caused by drilling operations. Second, the table for the most part is quite flat. I took several looks from front to back and found that near the table insert is where the dips showed up. You can not reliably check where the insert is so I skipped that area. The flattest areas were next to the miter slots.

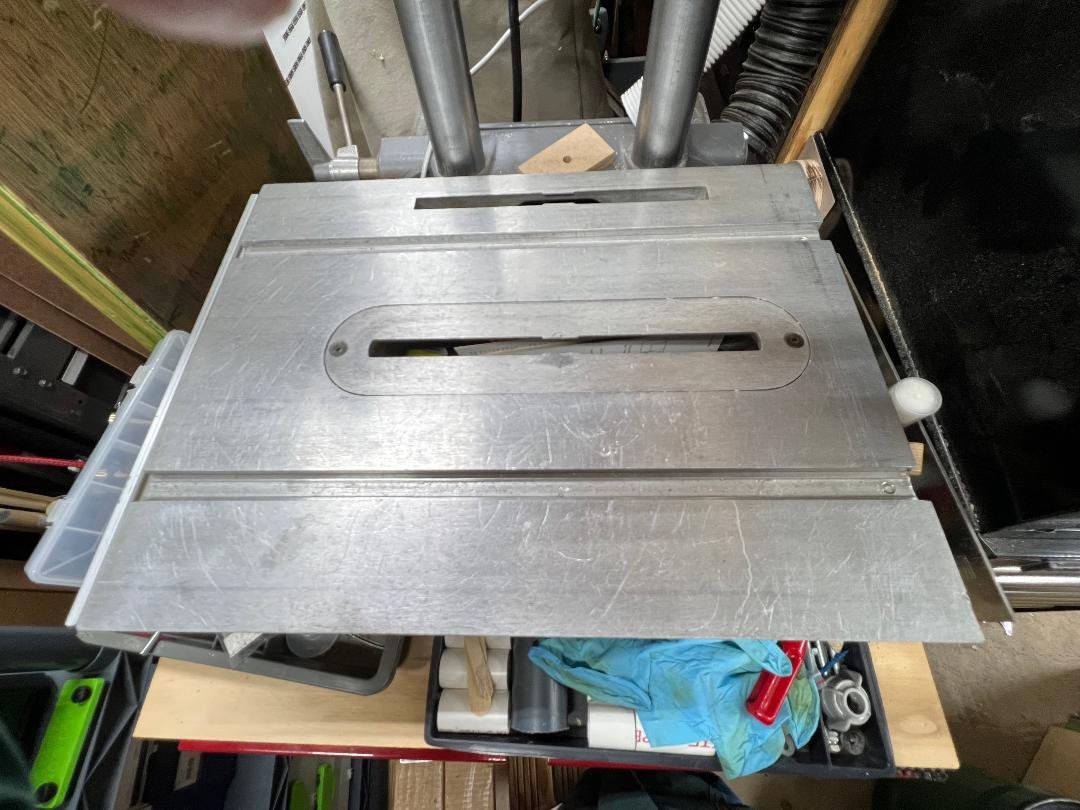

So this is the table I measured. It is from a 1976 shopsmith that I purchased new from shopsmith. It was my prime table for 30ish years. As you can see it has some use over those years.

- flatt1.jpg (159.57 KiB) Viewed 1302 times

For this testing I used a Woodpecker straight edge, about the straightest edge most wood shops have. I put a light behind so I could look for gaps. For the most part there were not any. In this shot you see a very small gap that is very short, it is just before where the insert goes.

- flatt2.jpg (194.58 KiB) Viewed 1302 times

The only large gap was slightly farther back on the table and just on the other side of the insert. The two gaps do not line up so farther proof that it is unlikely caused by drilling operations.

- flatt3.jpg (201.24 KiB) Viewed 1302 times

Using a feeler gauge that gap came in at .006" max. It is also a small area so my guess is that it has had no effect on operation of the shopsmith.

I have several more 500 tables but they are not easy to get at. I would think from using them that none are at the point of causing errors in my projects. Perhaps when warmer weather comes along I can check them too.

Ed

Re: Table flatness

Posted: Wed Jan 04, 2023 9:11 pm

by Hobbyman2

JPG wrote: ↑Wed Jan 04, 2023 9:51 am

- disconnect it from the trunnions and mount it like a floating table (using the table rails and tubes and no trunnions).

How does one do THAT with a M5/500?

------------------

Adapter plate ?

Re: Table flatness

Posted: Thu Jan 05, 2023 2:18 am

by JPG

Hobbyman2 wrote: ↑Wed Jan 04, 2023 9:11 pm

JPG wrote: ↑Wed Jan 04, 2023 9:51 am

- disconnect it from the trunnions and mount it like a floating table (using the table rails and tubes and no trunnions).

How does one do THAT with a M5/500?

------------------

Adapter plate ?

???

Re: Table flatness

Posted: Thu Jan 05, 2023 1:09 pm

by Hobbyman2

JPG wrote: ↑Thu Jan 05, 2023 2:18 am

Hobbyman2 wrote: ↑Wed Jan 04, 2023 9:11 pm

JPG wrote: ↑Wed Jan 04, 2023 9:51 am

- disconnect it from the trunnions and mount it like a floating table (using the table rails and tubes and no trunnions).

How does one do THAT with a M5/500?

------------------

Adapter plate ?

???

==================

yep ,, adapter plate , they adapt something to something else . seen a 4 cyl boat motor put into a 57 chevy on the show Cuban Chrome using a couple of adapter plates .

Re: Table flatness

Posted: Thu Jan 05, 2023 1:56 pm

by edma194

Don't know what happened to my previous post bring this up:

This website claims tolerance for some Grizzly saw table is .0175" ± .0025 -

https://sawmillcreek.org/showthread.php ... w-table-be. That's unconfirmed but seems realistic based on other specs, and I'd expect them mostly to be somewhat overstated.

I started looking for that thinking it might be something like 0.01" +/-0.005" but that may have been optimistic. I haven't found the authoritative source on granite plate deviation but it seems to be typically around 0.001 or slightly more. This usually gets measured within some radius in inches so flatness over something even as small as a 500 table may still have greater deviation over its entire surface area. Some woodworkers claim plate glass is just as good as granite, but in both materials the dimensional stability is limited by the thickness of the material and supporting structure.

Something around 0.015" or 1/64" would seem flat enough for a table saw in my opinion, and experience has shown me much worse doesn't have to be a show stopper.