Page 8 of 9

Re: Mark VII

Posted: Mon Dec 12, 2016 11:47 am

by stdavis

I did see a YouTube video on a speed control from a 3D printer. It appeared to be as good as the original. (LOVE to have one :-). ) I also saw posts about the CNC programming concerning the cam curve. Both being impressive. (I am also an EE). MHO is that the curve will suffice for the purpose of the cam. I believe that a significant design flaw in the original SS M7 cam interface is the excessive play between the cam and the driving yoke that contains the two roll pins. This causes chatter of the yoke drag in the backside of that yoke against the face of the bearing causing eventual failure and dismemberment of the bearing ball retaining plate nearest the yoke. That is based on my observations and experience over 50 years with my Mark VII. I read that clearance had been reduced for the CNC model. A great step in the right direction for you.

Re: Mark VII

Posted: Mon Dec 12, 2016 11:59 am

by stdavis

I failed to answer a question. I have used the Mark VII at table saw speed quite a bit, but also used a lot for lathe work, disc, drum and belt sanding. The band saw rarely leaves the end of the machine. (Although lately it has found a parking space on the Mark V. I have a spindle shaper and drill presses so the Mark VII doesn't get use there. I personally feel speeds above the saw setting are too aggressive for the design and I avoid those. (Remember....I am kind to my machines. :-). )

Re: Mark VII

Posted: Mon Dec 12, 2016 3:58 pm

by JPG

stdavis wrote:I did see a YouTube video on a speed control from a 3D printer. It appeared to be as good as the original. (LOVE to have one :-). ) I also saw posts about the CNC programming concerning the cam curve. Both being impressive. (I am also an EE). MHO is that the curve will suffice for the purpose of the cam. I believe that a significant design flaw in the original SS M7 cam interface is the excessive play between the cam and the driving yoke that contains the two roll pins. This causes chatter of the yoke drag in the backside of that yoke against the face of the bearing causing eventual failure and dismemberment of the bearing ball retaining plate nearest the yoke. That is based on my observations and experience over 50 years with my Mark VII. I read that clearance had been reduced for the CNC model. A great step in the right direction for you.

I have to inquire if the 'yoke' was installed correctly(it can be installed 'reversed' and does not work well).

Re: Mark VII

Posted: Mon Dec 12, 2016 5:41 pm

by reible

I have no interest in this other then I came across some notes I had saved from back in the day when I was in school and studying materials. The very early types of nylon had a 220degree C melting point. The newer versions got that up to 265 degree C. How ever the continuous service temperature was only 223 degree C. Keep in mind that is pretty hot but no where near what any sort of metal would be at. Lowly lead is about 327 degrees C.

Now this come to the question of the melting point of 3d printed parts, and of course what material was used. However plastic like ABS are amorphous but I gather from a few searches that printers work in the temperature ranges below the range of 230 C maximum of natural ABS.

From a cursory glance it would appear the plastic version is not much different then the original nylon. Again this is just an observation from the little I looked into the subject.

Ed

Re: Mark VII

Posted: Mon Dec 12, 2016 11:14 pm

by stdavis

Yes, the yoke is indeed tapered. Good point, though. Being heavier on the thicker side causes the yoke to naturally (gravitationally) place itself upside down. Gotta flip it over before threading in the speed control.

Re: Mark VII

Posted: Mon Dec 12, 2016 11:47 pm

by JPG

stdavis wrote:Yes, the yoke is indeed tapered. Good point, though. Being heavier on the thicker side causes the yoke to naturally (gravitationally) place itself upside down. Gotta flip it over before threading in the speed control.

The 'criteria' for the yoke is that the thicker side is towards the cam side with a decreasing od. Thus the thinner side is towards the cam side with increasing od. When the cam is rotated, the increasing od side will press against the yoke thus helping it move the sheave away. The tapered yoke surface will be tangent to the cam. If reversed, the yoke will bind on the cam.

Picky little 'detail'.

Also like the anti rotational spring clip on the Mark 5/V, the pins on the yoke should not pull on the control sheave. However too rapid adjustment towards fast can cause that pulling if the floating sheave does not keep up.

Re: Mark VII

Posted: Tue Mar 07, 2017 10:12 pm

by alohacnc

Awesome find. The extra design features on the old Mark VII are superior in my opinion. I found one for $40 and needed a lot of work. I have a thread on my process here...

http://www.shopsmith.com/ss_forum/commu ... 18522.html

One thing I'm particularly happy with was threading some tube for the tables so I can swap the tables with my modern Mark 5 and this Mark VII.

Re: Mark VII

Posted: Wed Sep 04, 2019 11:18 am

by jerclanc24

I know I'm way late to the party but does anyone know where I can find the all elusive cam. I need one for my machine and have read through the threads but cant seem to find if anyone still has any available

Re: Mark VII

Posted: Wed Sep 04, 2019 11:55 am

by chapmanruss

Because the Mark VII was made in the 1960's by Magna American, the company making the Shopsmith tools at the time and not the current makers of the Shopsmith Mark V and new Mark 7, parts are hard to find. Shopsmith Inc. long ago sold out of the Mark VII replacement parts they recieved when they purchased the Shopsmith line in 1972. Adding to that problem is the differences in the Mark 5/V speed control components and those of the Mark VII. There have been some people with 3D printers making replacement cams for the Mark VII speed control and selling them on eBay from time to time. I have even seen one made out of cast metal for sale a few years ago. The seller didn't want one that could melt again and made extras to sell. Very, very rarely does a used OEM cam come up for sale since it is the most common part needing replacement on the Mark VII.

Re: Mark VII

Posted: Wed Sep 04, 2019 11:58 am

by rjent

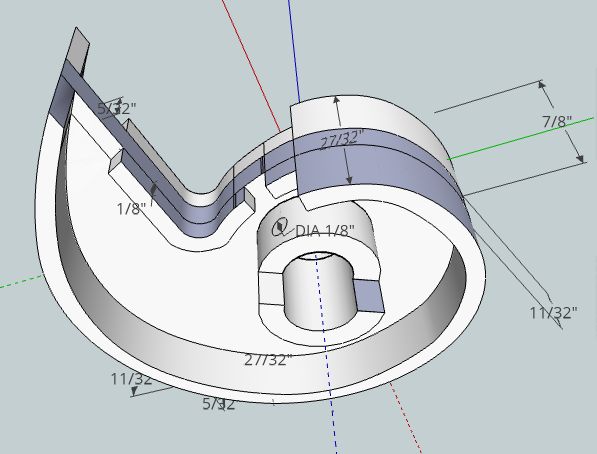

The cams are no longer available from anyone as russ pointed out. Occasionally one will become available on ebay, but it is rare. You can get drawing and tech info here for having a machine shop make one for you. It won't be cheap as a one off, but at least it would get you going. I will find the links....

OK, from Everett's Google drive find this machinists drawing. Let us know if you are successful!

https://drive.google.com/drive/folders/ ... sp=sharing

Better yet:

- Mark VII Cam 3D View.jpg (34.8 KiB) Viewed 14092 times