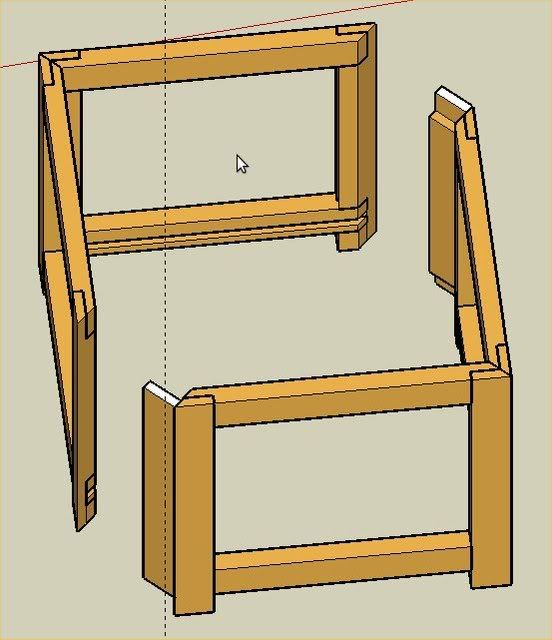

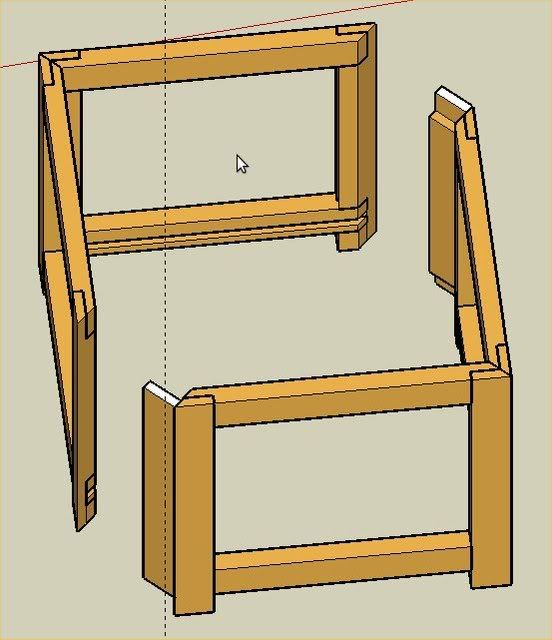

What are you going to cut your rails 4-1/2" long rails with 1/2" laps too? Cut to spec, those two dimensions make up the 3-1/2" opening. In your sketchup view, what you gain on one side by making the stiles thinner, you are going to loose on the other side of the glass.heathicus wrote:Ok, here's the quick Sketchup I did. End view of the stiles on two corners and two panes of glass. Done very quick, NOT to scale or using accurate measurements.

The "before" picture. The horizontal pane of glass barely fits on the stile on the left.

[ATTACH]8837[/ATTACH]

The "after" picture. I did not change anything about the glass. All I did was make the stiles a little thinner (I did not change the width), then put everything back together.

[ATTACH]8839[/ATTACH]

Now, the glass has more room to overlap the stile on the left.

Heath's Woodworking Projects

Moderator: admin

- mickyd

- Platinum Member

- Posts: 2999

- Joined: Mon Feb 09, 2009 1:18 pm

- Location: San Diego, CA

- Contact:

Mike

Sunny San Diego

Sunny San Diego

My rails may not be 4-1/2" long. They're probably going to be a little shorter now. But not by much - maybe 1/8"? But, they'll be cut to the length necessary to fit the stiles, whatever that length ends up being.mickyd wrote:What are you going to cut your rails 4-1/2" long rails with 1/2" laps too? Cut to spec, those two dimensions make up the 3-1/2" opening.

I'm not quite sure I understand what you're saying. Nothing changes with the glass. Just how the stiles and rails fit around the glass.mickyd wrote:In your sketchup view, what you gain on one side by making the stiles thinner, you are going to loose on the other side of the glass.

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

- JPG

- Platinum Member

- Posts: 35430

- Joined: Wed Dec 10, 2008 7:42 pm

- Location: Lexington, Ky (TAMECAT territory)

If I understand what you are doing, you are overlapping the glass at the four corners. That makes the glass too narrow!

Instead put the glass (inside)corner to (inside)corner and space ball/whatever the outer edges away from the corner of the stiles. The space is square xsection with side dimensions = to the thickness of the glass.

P.S. That 1/16" becomes a 'too wide' issue!

Instead put the glass (inside)corner to (inside)corner and space ball/whatever the outer edges away from the corner of the stiles. The space is square xsection with side dimensions = to the thickness of the glass.

P.S. That 1/16" becomes a 'too wide' issue!

╔═══╗

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

- mickyd

- Platinum Member

- Posts: 2999

- Joined: Mon Feb 09, 2009 1:18 pm

- Location: San Diego, CA

- Contact:

The glass isn't too 'narrow' if dimensions are to specs.JPG40504 wrote:If I understand what you are doing, you are overlapping the glass at the four corners. That makes the glass too narrow!

Instead put the glass (inside)corner to (inside)corner and space ball/whatever the outer edges away from the corner of the stiles. The space is square xsection with side dimensions = to the thickness of the glass.

P.S. That 1/16" becomes a 'too wide' issue!

Your space ball suggestion does work to center the 3-9/16" wide glass in the 3-1/4" stile to stile opening but they aren't needed to ensure that the glass edges don't show. It's a real good idea though.

Mike

Sunny San Diego

Sunny San Diego

- mickyd

- Platinum Member

- Posts: 2999

- Joined: Mon Feb 09, 2009 1:18 pm

- Location: San Diego, CA

- Contact:

Dollars to donuts you'll be a 'cut glass AFTER woodwork' convert before you've completed this project. A less complex design problably doesn't matter as much but with this one, where there are 5 cuts that determine the inside width of the lanern, you'll become a believer, hopefully not the hard way....heathicus wrote:Back to the task at hand. I didn't get this project ......

Another point for the "having the glass first" argument. I can't make the glass thinner. I don't even want to think about trying to shave 1/16" off the width of the glass. But so far, I've been successfully working the wood to fit the glass instead of working the glass to fit the wood.

Mike

Sunny San Diego

Sunny San Diego

Took some time off from the lanterns to make this.

What is it? My son recently got a hand-me-down bunk bed. His night stand was no longer in reach so he wanted a shelf. Just something to put his phone (which he uses as an alarm clock) and his book on. So this is what I came up with. I made it out of hand-me-down wood. A piece of ash for the main shelf and scrap African Mahogany for the trim/lip around the edge. I put on 3 coats of Helmsman Spar Urethane. I didn't go by any plans. Just started cutting and made it up as I went along.

To hook it on his bed I found a couple middle supports for hanging window blinds. (And that is why I never throw anything away!) They're ugly but they work.

What is it? My son recently got a hand-me-down bunk bed. His night stand was no longer in reach so he wanted a shelf. Just something to put his phone (which he uses as an alarm clock) and his book on. So this is what I came up with. I made it out of hand-me-down wood. A piece of ash for the main shelf and scrap African Mahogany for the trim/lip around the edge. I put on 3 coats of Helmsman Spar Urethane. I didn't go by any plans. Just started cutting and made it up as I went along.

To hook it on his bed I found a couple middle supports for hanging window blinds. (And that is why I never throw anything away!) They're ugly but they work.

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

I would have never guessed these lanterns would be this time consuming! Despite updates (and really I don't really see much of a need for updates as I'm just repeating a MickyD project), I have been working on them from time to time.

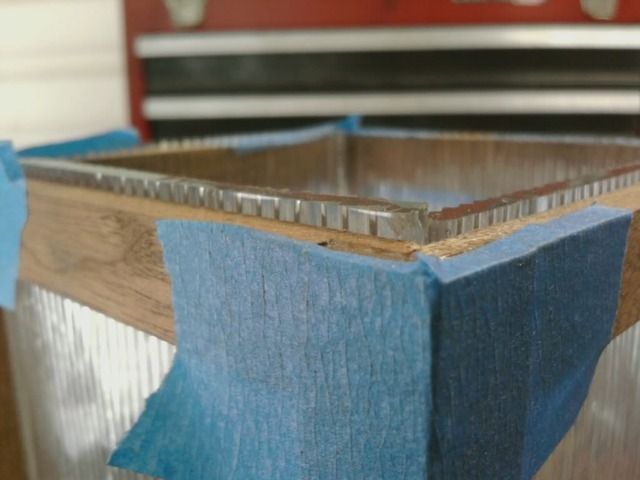

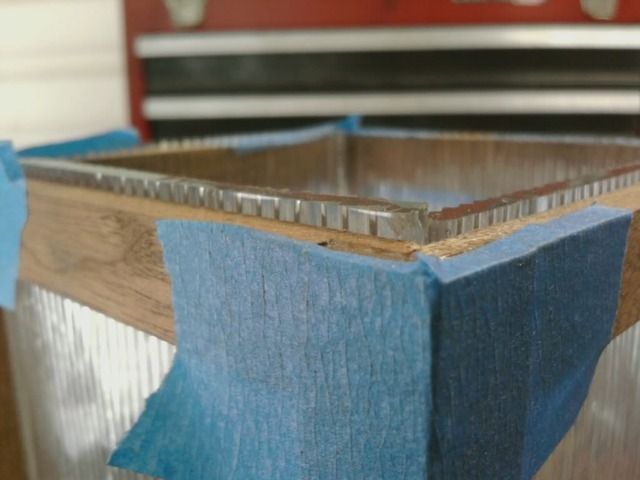

I though I would share a couple of problems I faced and how I fixed them. The first problem was... well, remember way back when I said this?

That protruding glass means the top decorative edging (I don't know what it should really be called, but I call it a "topper") won't set on top of the lantern. So does this move a point to the "cut the glass last" argument? Not really. Even though trimming the glass was too difficult due to how little there was to trim, it was quite easy to work around by working the wood. I simply cut a groove down the topper pieces to fit over the glass.

The other problem I ran in to really made me fear my mom was only going to get 2 lanterns instead of 3. I'm not sure how it happened, but the sides for the third, smallest lantern turned out too narrow. When I did a test fit, if I put the sides together in opposing corners, the other opposing corners had about a 1/8" gap between them. I could trim the base piece to bring them together, but then the glass wouldn't fit. After sweating over it (quite literally - heat index of ~105 here!) I decided to try to patch it and came up with an idea. I went ahead and glued up two sets of two sides so I had two halves of the lantern frame. Then I extended the other corners with a couple pieces that were originally supposed to be stiles for this lantern but became scrap when I cut the half-lap joints wrong.

The image above shows the extension being shorter than the stile, but in reality it is the same length.

Then I trimmed the extension using the table saw, going through a cycle of taking off a "hair" and test fitting and repeating until everything fit perfectly. After sanding and rounding over all of the corners, it's barely noticeable!

Still not finished, but I'm getting close! I've got to get this wrapped up, though. We're moving soon, so as soon as I finish this project I've got to start packing up my shop and move everything to storage until a new shop is built.

I though I would share a couple of problems I faced and how I fixed them. The first problem was... well, remember way back when I said this?

Well... I didn't make that adjustment on one of the lanterns and ended up with the glass sticking above the sides of the lantern." wrote:I miscalculated something and my glass came out about 3/16" longer than the plans called for. Good thing I cut the glass before cutting my wood to length! All I have to do is just adjust how long I cut the stiles and where I cut the half lap joints for the rails. That's a point for the "cut the glass first" argument.

That protruding glass means the top decorative edging (I don't know what it should really be called, but I call it a "topper") won't set on top of the lantern. So does this move a point to the "cut the glass last" argument? Not really. Even though trimming the glass was too difficult due to how little there was to trim, it was quite easy to work around by working the wood. I simply cut a groove down the topper pieces to fit over the glass.

The other problem I ran in to really made me fear my mom was only going to get 2 lanterns instead of 3. I'm not sure how it happened, but the sides for the third, smallest lantern turned out too narrow. When I did a test fit, if I put the sides together in opposing corners, the other opposing corners had about a 1/8" gap between them. I could trim the base piece to bring them together, but then the glass wouldn't fit. After sweating over it (quite literally - heat index of ~105 here!) I decided to try to patch it and came up with an idea. I went ahead and glued up two sets of two sides so I had two halves of the lantern frame. Then I extended the other corners with a couple pieces that were originally supposed to be stiles for this lantern but became scrap when I cut the half-lap joints wrong.

The image above shows the extension being shorter than the stile, but in reality it is the same length.

Then I trimmed the extension using the table saw, going through a cycle of taking off a "hair" and test fitting and repeating until everything fit perfectly. After sanding and rounding over all of the corners, it's barely noticeable!

Still not finished, but I'm getting close! I've got to get this wrapped up, though. We're moving soon, so as soon as I finish this project I've got to start packing up my shop and move everything to storage until a new shop is built.

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

- mickyd

- Platinum Member

- Posts: 2999

- Joined: Mon Feb 09, 2009 1:18 pm

- Location: San Diego, CA

- Contact:

Great thinking outside the box heathicus!! Excellent solutions to your issues. Nice job.

If you haven't glued your top pieces / miters together yet, you may need to consider making the glass relief groove even a little wider than shown in order to get tops to fit properly. You'll want to do a dry fit for sure to determine if the groove you added interferes with the 45° miters closing up properly. Depending on your actual lantern and top dimensions, your relief groove MAY have to be widened on both faces.....a little off the inside and outside surface. Hard to explain but you'll see what I mean or if it's even relevant when you do a dry fit.

So are you seeing the advantages of waiting to cut the glass AFTER all the woodwork / assembling is done yet?? From the outside looking in, I sure do.

If you haven't glued your top pieces / miters together yet, you may need to consider making the glass relief groove even a little wider than shown in order to get tops to fit properly. You'll want to do a dry fit for sure to determine if the groove you added interferes with the 45° miters closing up properly. Depending on your actual lantern and top dimensions, your relief groove MAY have to be widened on both faces.....a little off the inside and outside surface. Hard to explain but you'll see what I mean or if it's even relevant when you do a dry fit.

So are you seeing the advantages of waiting to cut the glass AFTER all the woodwork / assembling is done yet?? From the outside looking in, I sure do.

Mike

Sunny San Diego

Sunny San Diego

The toppers are glued up already for the large and medium lanterns. I cut each of the four topper pieces for each lantern a little long, then sanded each one for a custom and perfect fit, dry fitting the entire assembly along the way. I understand what you're saying about the groove, but it ended up being plenty wide enough for "wiggle room." The kerf of the blade wasn't wide enough for the glass to fit, so I had to make the groove in two passes.mickyd wrote:If you haven't glued your top pieces / miters together yet, you may need to consider making the glass relief groove even a little wider than shown in order to get tops to fit properly. You'll want to do a dry fit for sure to determine if the groove you added interferes with the 45° miters closing up properly. Depending on your actual lantern and top dimensions, your relief groove MAY have to be widened on both faces.....a little off the inside and outside surface. Hard to explain but you'll see what I mean or if it's even relevant when you do a dry fit.

I have to say no. At least for this project. In fact, I think it reinforces the "cut the glass first" argument. What if I had cut and assembled the sides and toppers before cutting the glass, then accidentally cut the glass 3/16" long? Or cut them long by even less of a margin - like 1/32". Just enough so the topper wouldn't sit flush on top of the lantern. It's really hard to trim that small of an amount from the glass. But it would also be too late to cut a relief groove in the topper pieces (except by hand with a chisel). Cutting the glass first, then working the wood to fit it has worked fine so far.mickyd wrote:So are you seeing the advantages of waiting to cut the glass AFTER all the woodwork / assembling is done yet?? From the outside looking in, I sure do.

A different project might lead me to a different conclusion, but so far, and for this project, I'm not convinced that it would have been best to cut the glass last.

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration