Page 1 of 3

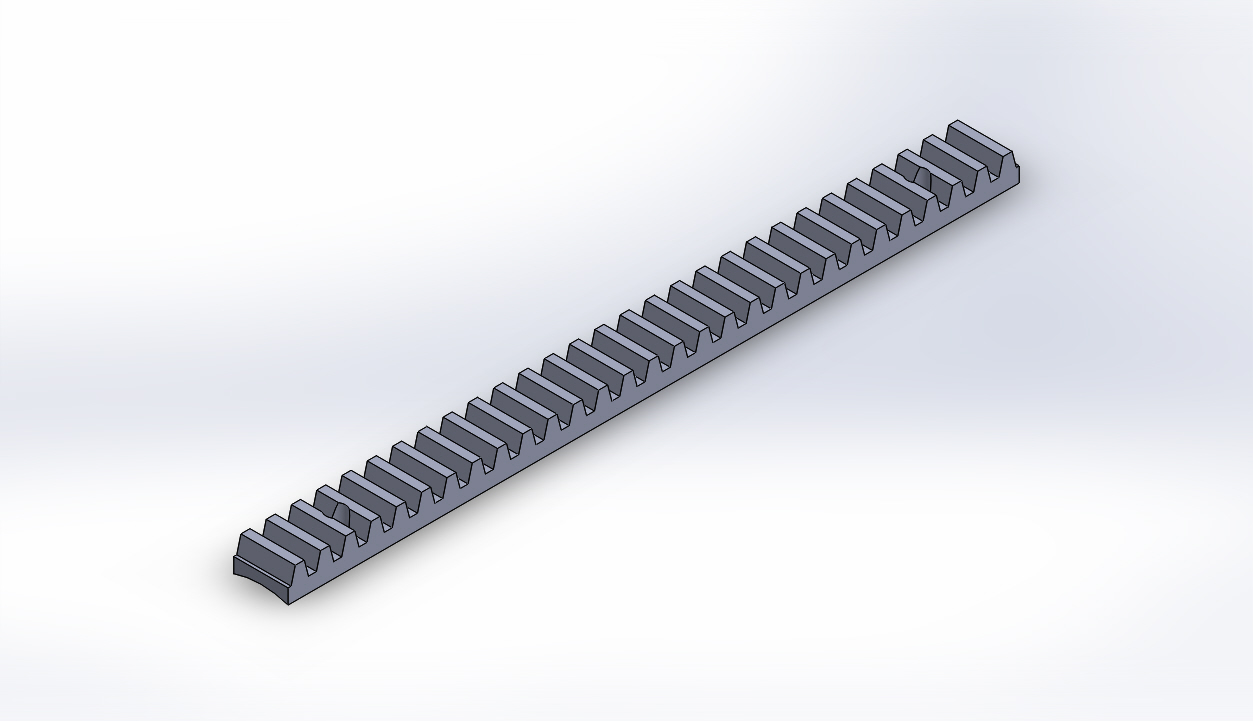

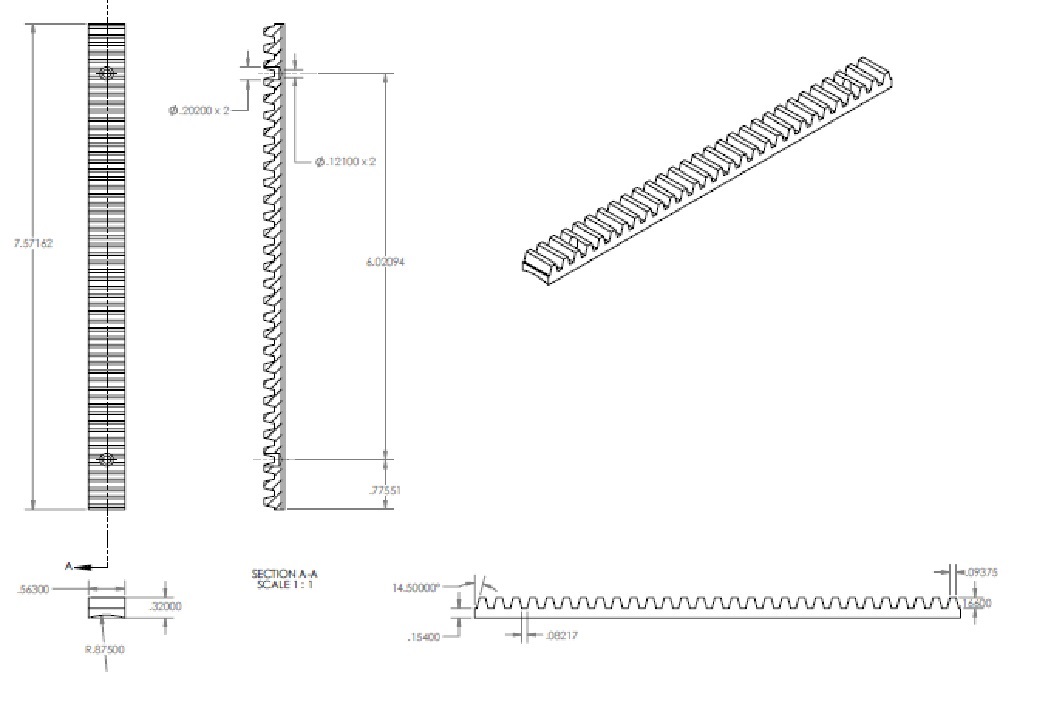

Mark VII gear rack

Posted: Tue Oct 20, 2015 11:39 am

by richardrouse

- gear rack.JPG (141.36 KiB) Viewed 8799 times

- gear rack print.jpg (79.7 KiB) Viewed 8799 times

Thanks to JPG for doing the leg work on this one. The model was drawn from a print that he included in another thread.

I've got the model drawn for the gear racks, I'm waiting on a part for my 3d printer to print the first iteration of this part.

Re: Mark VII gear rack

Posted: Tue Oct 20, 2015 6:28 pm

by JPG

Unless I missed something, it looks good to me. I noticed you added slight clearance for adjacent sections.

I assume you got good definition on the tooth shape. I did not.

Re: Mark VII gear rack

Posted: Tue Oct 20, 2015 7:59 pm

by richardrouse

I did add clearance at the end to allow for end clearance. I'm hoping that the sections will align.

I used my trusty machinist rule and magnifying glass to get a profile of the teeth. I'm fairly confident that it is correct.

The best test now will be seeing how this piece compares with the old piece.

Unfortunately, I've got some issues with the 3d printer right now.. for some reason i'm tripping a thermal overload on one of the heating elements. The service guy suspects it is a bad fan and is sending me one. I'm just glad that I got the extended warranty.

Re: Mark VII gear rack

Posted: Tue Oct 20, 2015 8:30 pm

by JPG

richardrouse wrote:I did add clearance at the end to allow for end clearance. I'm hoping that the sections will align.

They should align, Each new section uses the

outer mounting holes of the original section.

One new hole for each new section will be required. They are +-0.785 from the original center mounting hole.

Re: Mark VII gear rack

Posted: Tue Oct 20, 2015 8:52 pm

by rjent

This is awesome!

I truly hope this works (as I am sure many are). I will try to find a Mark VII if these various parts can be made, what an amazing machine the M VII is, particularly for when it was made.

Re: Mark VII gear rack

Posted: Tue Oct 20, 2015 10:26 pm

by richardrouse

Jpg, my concern for alignment is with that 1/32 gap at the front and rear of the piece. Those ridges that are left behind due to the nature of my 3d printers operation sometimes affects the way two pieces mate together. Worst case, some sanding might need to be done to ensure tight mates with proper tooth spacing.

Rjent,

I'm fairly certain this will work. My major concern with the material had to do with its thermal properties. I've now ran my headstock for 45 minutes straight with the 3d printed control cam and changes speeds periodically. The can I used showed no signs of wear or degradation due to heat build up.

Of course, that is with a well lubed control sheave assembly!

Imho, the only potential problem s are dimensional ones, in regard to the teeth. If I got those wrong, they are easy enough to change... It s more an issue of when this works.. Not if.

Re: Mark VII gear rack

Posted: Tue Oct 20, 2015 10:44 pm

by JPG

By using the original holes, 4 of the eight ends will be positioned correctly. The adjoining ends can be 'tweaked' at assembly.

Re: Mark VII gear rack

Posted: Wed Oct 21, 2015 11:03 am

by richardrouse

indeed! my goal is to have minimal tweaking neccessary

Re: Mark VII gear rack

Posted: Thu Oct 22, 2015 8:42 pm

by richardrouse

Re: Mark VII gear rack

Posted: Thu Oct 22, 2015 10:32 pm

by JPG

Yes it does pant pant pant!!!