Page 1 of 4

End Grain Mortising

Posted: Tue Aug 15, 2017 8:17 am

by dafixer

Good morning y'all!

I've been tasked with building 2 new side rails for a king size bed. The side rails are 82" long x 6" wide x 1" thick. The older side rails are made of heavy plywood and had the double hook hardware that would fit over 2 dowels in the headboard and footboard to make a snug fit. I'm not replacing anything on the headboard or footboard so my issue is this. The new rails will be either red oak or white oak.

I need to mortise a slot in the end grain of the new rails to install new hardware that matches the older hardware. See this link for the hardware.

http://www.rockler.com/bed-rail-hooks

Can I use the horizontal boring feature of my Mark V 520 to cut these mortises?

In searching the internet, I've only found one guy doing what I need to do and he didn't have a SS. He angled his side rails into a vise, beefed-up the sides of the rail and used his plunge router (at about a 40^ angle) to cut his mortises. Sounds a bit shaky to me, so I thought of using the SS horizontal boring feature. I'm wondering if I can use a mortise bit in the chuck, at high speed, safely to cut the slot. The slot needs to be not much more than 3/32" wide,1-1/8" deep and about 3-1/2" long along the end grain.

The other option is to just drill some very narrow holes and chisel them out. But at 3/32" wide, chiseling is iffy.

What say y'all?

Thanks in advance!

Re: End Grain Mortising

Posted: Tue Aug 15, 2017 11:58 am

by thunderbirdbat

You would need the mortising attachment. A mortising bit is basically a drill bit inside a square chisel. You could use a router chuck for slot mortising.

http://www.shopsmith.com/academy/routin ... m#mortises The hardware that you are using does not appear to need square ends on the mortise so it would basically be just routing the ends in the horizontal boring setup.

Re: End Grain Mortising

Posted: Tue Aug 15, 2017 12:27 pm

by Hobbyman2

Be sure to clamp some sort of brace on the out sides to keep the wood from splitting open , practice on a scrap piece .

The SS in horizontal boring set up would be my first choice.

Posted: Tue Aug 15, 2017 12:52 pm

by charlese

Yes! By all means you can and should use the horizontal boring set up to make these mortises.

I have done this often. In fact it is my favorite method to make end mortises. You don't need any new tools, other than a Shopsmith router bit chuck (either 1/4" or 1/2") and a router bit. Here's their router chuck:

http://www.shopsmith.com/ownersite/cata ... shield.htm

If you want, you can use the drill chuck and the appropriate size drill bit. Using this method, drill overlapping holes to form the mortise and clean out with a sharp chisel.

If you don't already have a router chuck the second method will probably serve you best. No additional money needed, and the mortises don't have to be real pretty because they will be hidden after the hook is inserted.

Caution!! Don't try to rout using your drill chuck. It is not designed for sideways pressure.

- Bench mortises.JPG (58.58 KiB) Viewed 21751 times

Re: End Grain Mortising

Posted: Tue Aug 15, 2017 1:06 pm

by masonsailor2

There is no way to do that narrow of a slot with drills and chisel. It is designed to have a slot made with either a fly cutter on a router table or a saw blade on a radial arm saw. If you have access to a radial arm saw it would be doable but in small increments to prevent the saw from grabbing. A simpler method would be to do a stepped mortise on the long piece with the second step being 3/32 deep. Then cut a piece to match the first step so that when you glue it on to the main piece it leaves the pocket you need. If you make the first step of the mortise big enough to give you say a two inch border for a gluing surface the end result should be more than strong enough. It could be done blind from the top and outside so it would not be seen. Think mortising in a hinge and then gluing a block on the door over the hinge. Do you have a router ? The router jig would be very simple to make and use a 1/2" or 3/4" straight bit. I am in the air at the moment but tomorrow I can give you a drawing tomorrow if you need it.

Paul

Re: End Grain Mortising

Posted: Tue Aug 15, 2017 7:28 pm

by JPG

Since the 'cover' piece can be on the inside of the rail, I think Paul's method is a good way.

Re: End Grain Mortising

Posted: Wed Aug 16, 2017 4:50 pm

by dynabase

This might be an option if you don't want to do the mortise. The brackets you reverenced are not suggested for new construction.

http://www.rockler.com/surface-mounted- ... l-brackets

Michael

Re: End Grain Mortising

Posted: Wed Aug 16, 2017 5:48 pm

by reible

Due to the width of the slot (mortise)(kerf) being just 3/32" I think it might be better to use a circular saw to make the cut. You could do it on the shopsmith if you feel you can control the length of the bed rail being up in the air and the end being on the saw table but I know I would not feel safe doing that..... so a circular saw seems to be a possible answer.

To get the 1-1/8" depth you would set the saw depth to that. Then clamp some wide boards, maybe 2x6's to each side of the rail flush with the end where you want to cut. This would provide better support for the saw base to ride on. An edge guide to locate the cut in the board would be needed unless you feel brave and what to try and cut to a line......

Then you have to make the cut from the bottom to the top. Depending on the width of the rail the saw blade may need to come through or not. If you wish you could just make it a through cut then cut a filler to repair that.

The width of a saw blade might be 3/32" or you may have to make a second cut if need to make it wide enough. Depends on the blade.

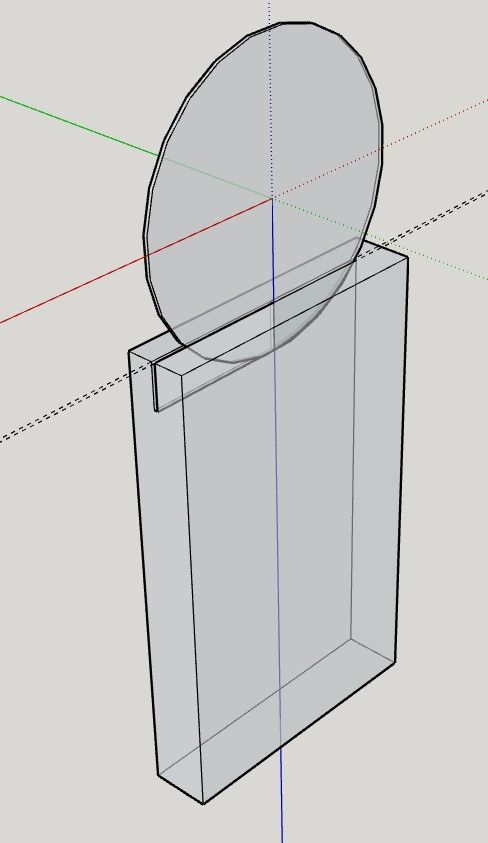

Since the blade is circle you end up with the radius left after you get the full depth for the length you need. The sketch is an approximation of what this would look like.

- ScreenHunter_01 Aug. 16 16.32.jpg (28.98 KiB) Viewed 21667 times

Ed

Re: End Grain Mortising

Posted: Wed Aug 16, 2017 5:54 pm

by rpd

Could you not cut it with a dado blade. The cut on the rail is open on the end and the bottom, and the hardware does not fill the whole slot, but slopes down from the end, so it probably isn't necessary to square off the inside corner.

Re: End Grain Mortising

Posted: Thu Aug 17, 2017 6:58 am

by Hobbyman2

If you havent bought those all ready May I suggest some thing a little different and less complicated.

https://www.amazon.com/No-Mortise-Bed-R ... TTZ492QMNQ

You could inlay them a little even.