Page 1 of 2

Round-over Question

Posted: Mon Nov 20, 2017 2:45 pm

by algale

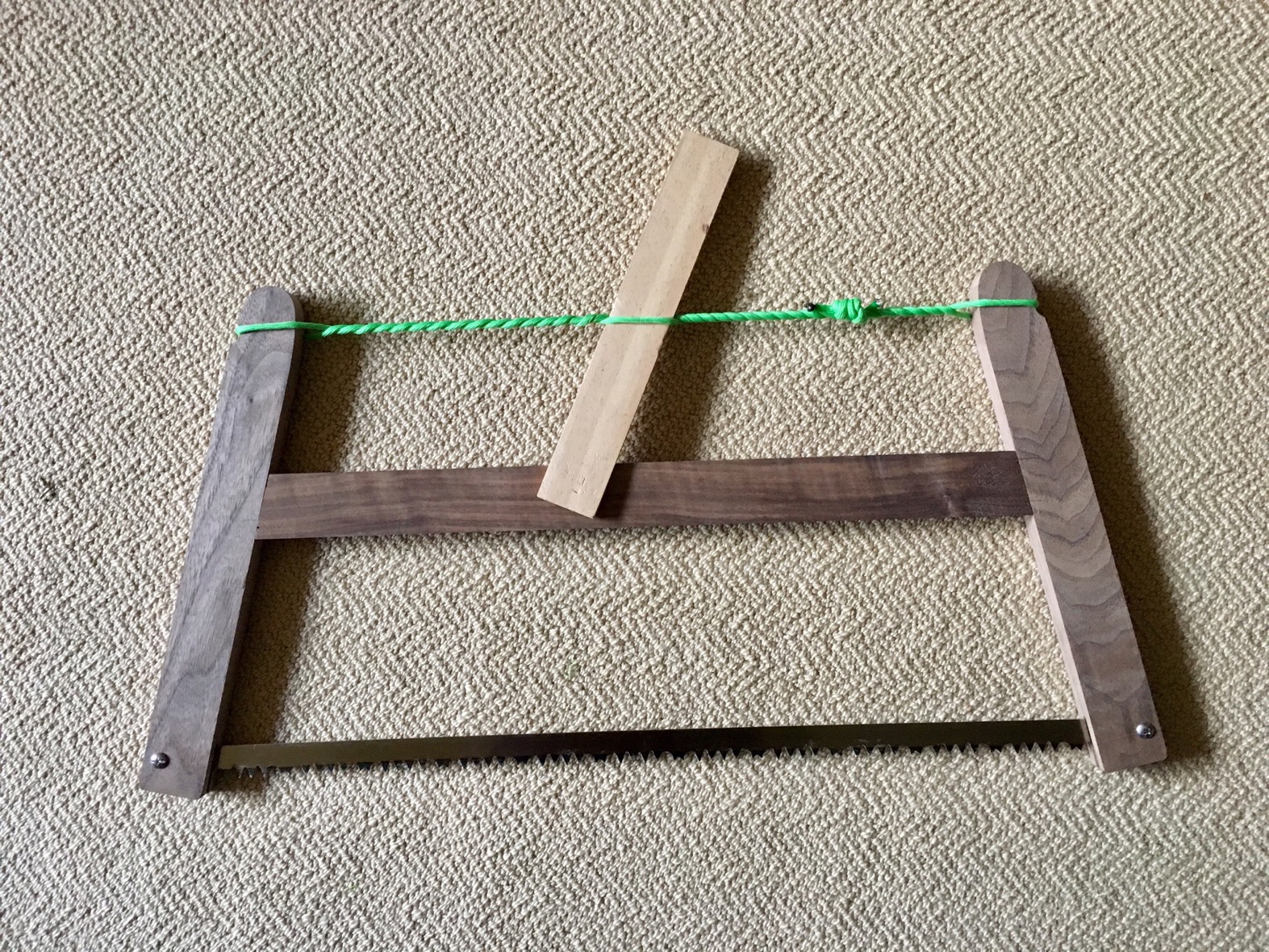

To make an understatement, I do not feel like I know what I am doing with a router. I want to round over the handles and cross brace of this buck saw but I don’t want to round over the areas where the horizontal brace is mortised into the upright handles. Further complicating matters is that the handles are slotted on the palm side of the grip because, with the Spanish windlass removed, the saw handles pivot around to store the blade. The stock is 3/4 thick.

There is also a notch where the windlass rope fits which is a semi circle, 1/2 inch in diameter.

I have a piloted 1/2 round over bit and have access to the overarm router , which I bought on a whim over a year ago when one popped up on eBay.

Oh, and the key for the windlass is being replaced by a piece of walnut; this was just a proof of concept.

Thanks for any advice or guidance.

- E79B254E-96E4-4DEE-803D-4F4C5E9CDA7C.jpeg (927.02 KiB) Viewed 19975 times

Re: Round-over Question

Posted: Mon Nov 20, 2017 3:10 pm

by terrydowning

Re: Round-over Question

Posted: Mon Nov 20, 2017 3:42 pm

by algale

Good lord, he used hand tools!

I know I could sand or rasp it; I was hoping to get a very precise machined round over. Maybe that's just not possible with this shape.

Re: Round-over Question

Posted: Mon Nov 20, 2017 3:53 pm

by reible

Router table with a starting pin is what I would use. Just stop/start before/after the areas you want to leave square.

Ed

Re: Round-over Question

Posted: Mon Nov 20, 2017 4:05 pm

by rpd

algale wrote:

Good lord, he used hand tools!

I know I could sand or rasp it; I was hoping to get a very precise machined round over. Maybe that's just not possible with this shape.

Stop the round over before you get to the cross member. This is a mortice and tenon joint on a three legged side table that I made back in high school.

- roundover transition.jpg (322.31 KiB) Viewed 19949 times

Re: Round-over Question

Posted: Mon Nov 20, 2017 4:37 pm

by jsburger

reible wrote:Router table with a starting pin is what I would use. Just stop/start before/after the areas you want to leave square.

Ed

That is exactly how I have done it. You need a bearing on the bit. You might want to mark some stop and start points on the stock for consistency (over shoot / under shoot).

Re: Round-over Question

Posted: Mon Nov 20, 2017 4:40 pm

by algale

jsburger wrote:reible wrote:Router table with a starting pin is what I would use. Just stop/start before/after the areas you want to leave square.

Ed

That is exactly how I have done it. You need a bearing on the bit. You might want to mark some stop and start points on the stock for consistency (over shoot / under shoot).

I do have a piloted 1/2" round-over.

Thanks everyone!

Re: Round-over Question

Posted: Mon Nov 20, 2017 4:41 pm

by jsburger

algale wrote:jsburger wrote:reible wrote:Router table with a starting pin is what I would use. Just stop/start before/after the areas you want to leave square.

Ed

That is exactly how I have done it. You need a bearing on the bit. You might want to mark some stop and start points on the stock for consistency (over shoot / under shoot).

I do have a piloted 1/2" round-over.

Thanks everyone!

That will work.

Re: Round-over Question

Posted: Mon Nov 20, 2017 5:18 pm

by algale

Is there a method (other than trial and error) for ensuring the round over is equal?

My sense is that if I carefully align the very lowest portion of the cutting surface of the bit (remember I'm using an overarm router) with the exact mid point of the stock, it should end up uniform and centered when I flip the work piece over.

Is that right?

Re: Round-over Question

Posted: Mon Nov 20, 2017 5:34 pm

by JPG

I leave the start/stop details for others to address, but I think a reference point would be 1/2 the bit radius (distance from the bit rotation center) to be used with a reference line on the router table.

I believe I would use a smaller radius round over.

I think under shoot is preferable to over shoot(slight extended squared off).