Page 1 of 1

Two Tools to use for Table to Blade Alignment

Posted: Wed Apr 21, 2021 1:03 pm

by dusty

There have been recent discussion about instrumentation that can be used to perform "Shopsmith Table to Blade Alignment".

The two Tools are the MAG-DRO and the SuperBar. I have both. Of the two I much prefer the SuperBar. The photo shots that I am presenting here clearly show either can be used to gather reliable data for their intended purpose.

This is not intended as a component review simply because there are too many factors that go into evaluating the whole tool that I have not documented.

I hope the photos speak fro them selves

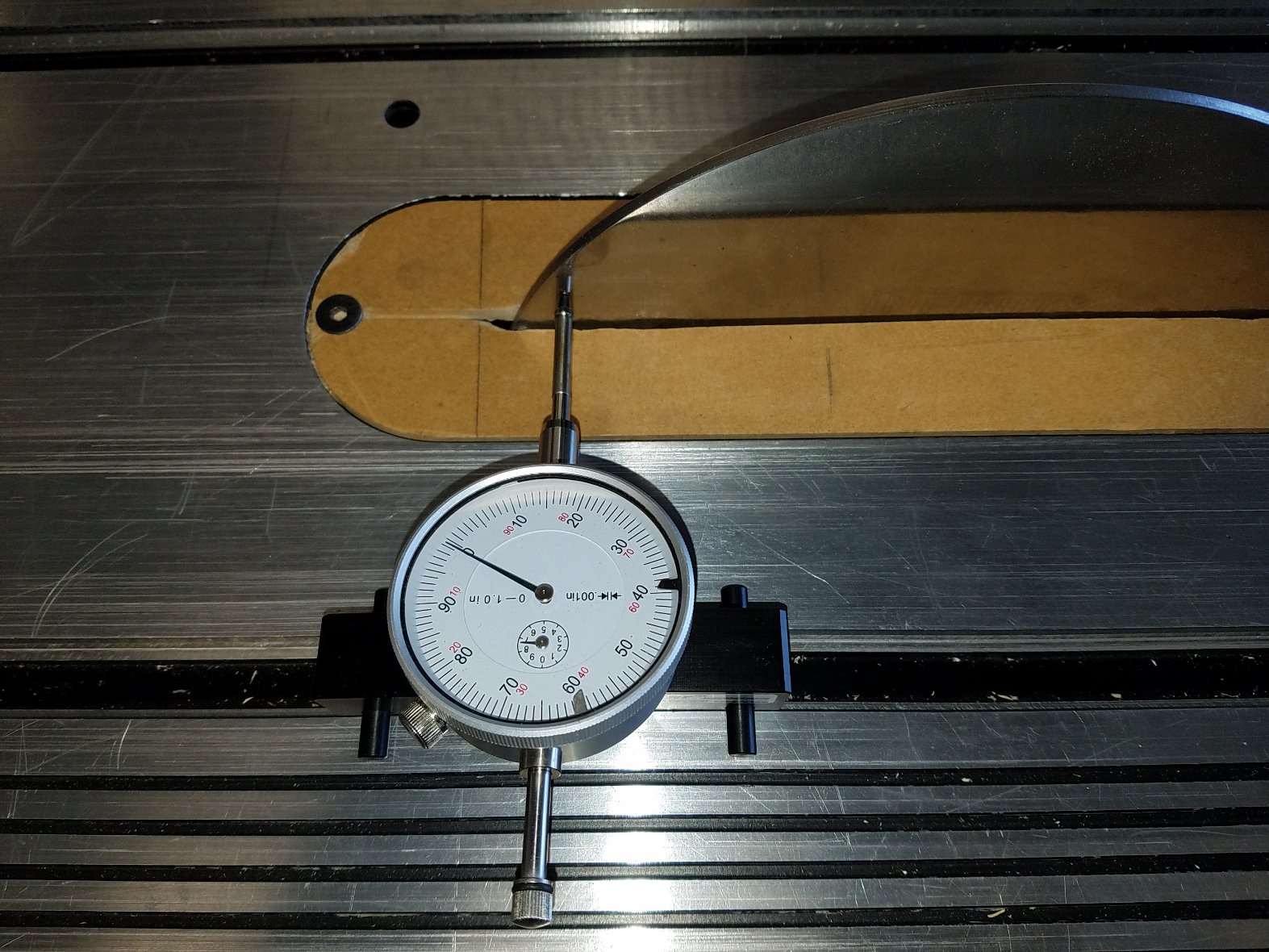

MAG-DRO:

- 20210421_093443.jpg (464.26 KiB) Viewed 2129 times

- 20210421_093514.jpg (473.43 KiB) Viewed 2129 times

- 20210421_093540.jpg (473.27 KiB) Viewed 2129 times

- 20210421_093619.jpg (418.95 KiB) Viewed 2129 times

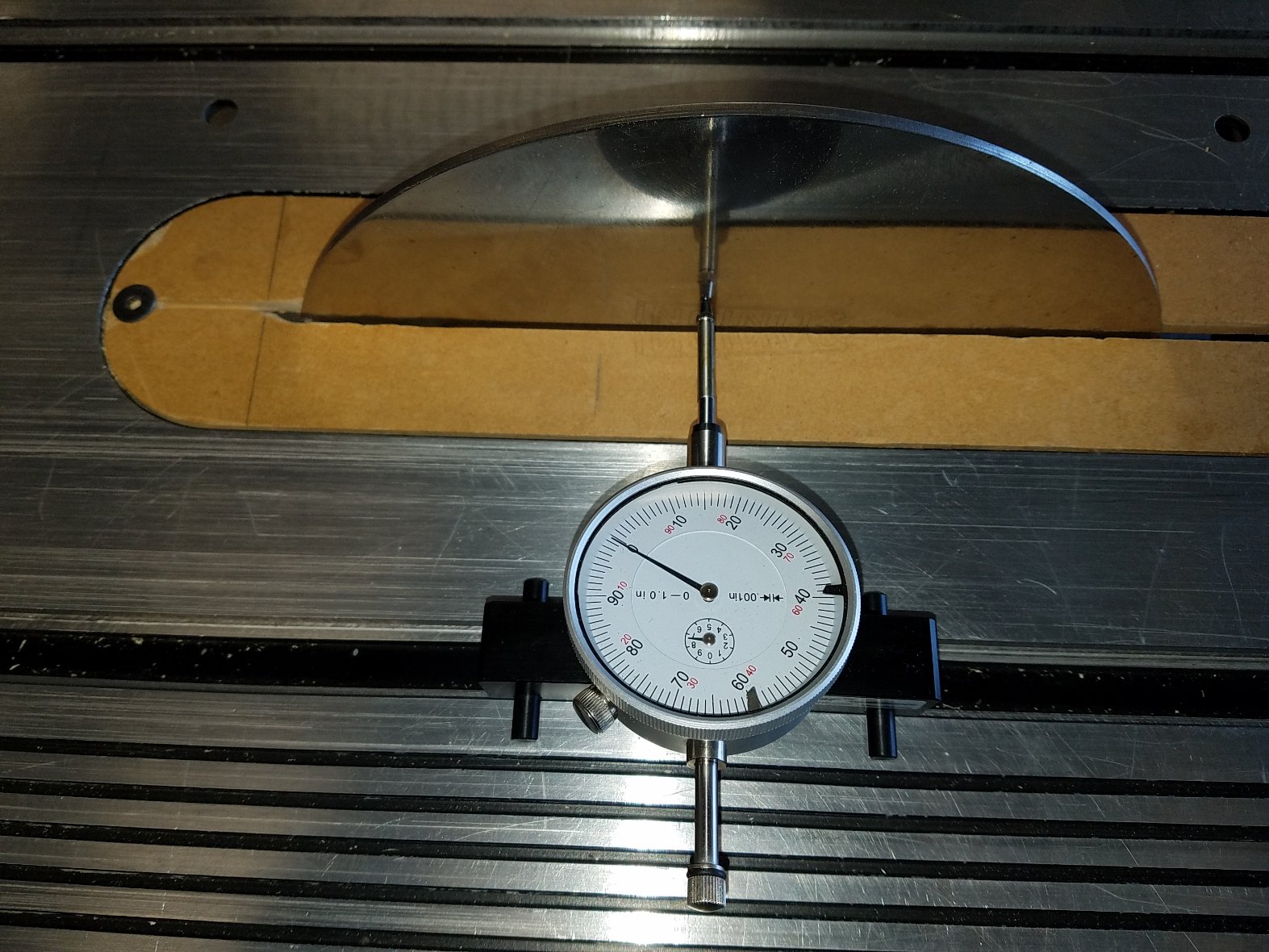

SuperBar:

- 20210421_093731.jpg (355.88 KiB) Viewed 2129 times

- 20210421_093747.jpg (331.47 KiB) Viewed 2129 times

- 20210421_093803.jpg (401.02 KiB) Viewed 2129 times

Re: Two Tools to use for Table to Blade Alignment

Posted: Wed Apr 21, 2021 2:17 pm

by bainin

Hey Dusty - your image of the dial gauge reminded me of thought i had when doing a setup.

It looks like the dial gauge is making an angle (possibly in 2 directions) to what would be the surface normal (the plate) . I had something similar due to something being in the way or wanting to land on my saw blade at a certain point ..i forget what exactly.

For a true reading of displacement-that dial indicator would need to be perpendicular to the measured surface right ? but maybe a true reading isn't important so long as the displacement on the indicator is small . I think if I remember my trig, that the displacement in this configuration would be larger than the actual displacement by cosine of the included angle.

b

Re: Two Tools to use for Table to Blade Alignment

Posted: Wed Apr 21, 2021 2:45 pm

by dusty

Something is not right in the pictures with the dial indicator. It should not be 0.000 in all three and that is what it looks like. The numbers with the MAG-DRO are near what I expected.

These images are real world. I cannot explain the three with no deflection at all.

- 20210421_113547.jpg (253.23 KiB) Viewed 2102 times

- 20210421_113605.jpg (261.9 KiB) Viewed 2102 times

- 20210421_113622.jpg (288.69 KiB) Viewed 2102 times

Re: Two Tools to use for Table to Blade Alignment

Posted: Wed Apr 21, 2021 3:35 pm

by RFGuy

One question...for the MAG DRO, how do you determine how hard to press on the caliper thumb wheel to get a measurement? At least with a dial indicator there is a consistent spring tension that follows whatever reference surface you are measuring. With the MAG DRO though you have to push on the thumb wheel of the caliper to register the caliper rod against the reference surface. I would expect it will be hard to use the same force every time to get consistent results using this. Also, when pushing on the thumbwheel can it introduce error through table, reference surface, MAG DRO, etc. flex from pushing on the caliper?

Re: Two Tools to use for Table to Blade Alignment

Posted: Wed Apr 21, 2021 4:49 pm

by dusty

Not applying force to that wheel greater than what is required to advance it is the trick to getting valid readings from the caliper. It is possible to introduce bad readings with too much force.

Being flat on the table as it is with the MAG-DRO, the caliper button is difficult to advance properly. I gently push on the body of the gage to move it. If a reading doesn't seem right - back off and do it again.

Can one introduce error - absolutely. Gentle, one-finger push and listen for contact.

The Infinity plate that I have rings when contacted by the caliper. There is a touch required. This is true in all applications using the caliper (dital or otherwise).

Re: Two Tools to use for Table to Blade Alignment

Posted: Wed Apr 21, 2021 4:59 pm

by dusty

bainin wrote: ↑Wed Apr 21, 2021 2:17 pm

Hey Dusty - your image of the dial gauge reminded me of thought i had when doing a setup.

It looks like the dial gauge is making an angle (possibly in 2 directions) to what would be the surface normal (the plate) . I had something similar due to something being in the way or wanting to land on my saw blade at a certain point ..i forget what exactly.

For a true reading of displacement-that dial indicator would need to be perpendicular to the measured surface right ? but maybe a true reading isn't important so long as the displacement on the indicator is small . I think if I remember my trig, that the displacement in this configuration would be larger than the actual displacement by cosine of the included angle.

b

Absolutely. The proper way is for the plunger to meet the reference surface at 90° (if the number is to be an accurate measurement of separation). Being used for this purpose we are looking for a reading that is consistently the same each and every time, indicating parallelism. If the plunger is at an angle, it is actually measuring the hypotenuse of the right triangle formed by the setup.

At an angle, the tip of the plunger can also side at point of contact.

What you cannot see in the corrected set of pictures is that the plunger bar is closer to being parallel to the table top.

Re: Three Tools to use for Table to Blade Alignment

Posted: Wed Apr 21, 2021 6:46 pm

by dusty

I have resurrected my very first dial indicator used for Table to Blade alignment.

I brought back the Shopsmith version. I think a comparison of the three is going to be interesting - and maybe an eye opener for me.

The Shopsmith and the SuperBar:

- The Shopsmith Dial Indicator Set-Up 555884

- 20210421_151538.jpg (303.26 KiB) Viewed 2042 times

- The SuperBar

- 20210421_151602.jpg (299.26 KiB) Viewed 2042 times

Re: Three Tools to use for Table to Blade Alignment

Posted: Thu Apr 22, 2021 12:22 pm

by miken

dusty wrote: ↑Wed Apr 21, 2021 6:46 pm

I brought back the Shopsmith version. I think a comparison of the three is going to be interesting - and maybe an eye opener for me.

I am looking forward to your results Dusty.

Question: do you rotate the infinity plate as you take a reading from the infeed side to the outfeed side? Or perhaps the infinity plate is certified flat and perpendicular to the shaft? I ask because I am only using my sanding disk and it is not flat, so I mark a dot on the edge and then rotate the disk to measure from the same exact point.

Thanks, Mike -

Re: Three Tools to use for Table to Blade Alignment

Posted: Thu Apr 22, 2021 12:42 pm

by dusty

miken wrote: ↑Thu Apr 22, 2021 12:22 pm

dusty wrote: ↑Wed Apr 21, 2021 6:46 pm

I brought back the Shopsmith version. I think a comparison of the three is going to be interesting - and maybe an eye opener for me.

I am looking forward to your results Dusty.

Question: do you rotate the infinity plate as you take a reading from the infeed side to the outfeed side? Or perhaps the infinity plate is certified flat and perpendicular to the shaft? I ask because I am only using my sanding disk and it is not flat, so I mark a dot on the edge and then rotate the disk to measure from the same exact point.

Thanks, Mike -

This really depends on how precise you want to be. Picking a spot for contact and rotating back and forth yields the most accurate alignment. The sanding disk should be treated like a blade to get reliable results. I use a disk from Infinity and I still mark a spot and rotate back and forth. No Shortcuts when doing alignments.