Page 1 of 2

520 table not aligning

Posted: Thu Nov 18, 2021 10:05 pm

by eagspoo

Hi, I have a 520 with a normal Mark V headstock and a Power Pro headstock (long story).

I think it was set up for the Power Pro headstock which is currently being rebuilt. When I use the table saw with the Mark V headstock, I slide the table left until it hits the rubber sleeve on the waytube, lock things in place, lower the table, and... it looks like it is off by 1/8" or so. Everything really does work ok like this but wondering if I have the wrong rubber spacing sleeve?

I've attached a couple pictures so people can see what I've got going on. In the photo showing the sleeve, it looks pretty snug on the bottom but there is a gap on the top of the sleeve, does that look right?

Thanks for any suggestions!

Re: 520 table not aligning

Posted: Thu Nov 18, 2021 10:26 pm

by garys

My rubber sleeve is in my parts box. I never installed it because it gets in my way when I try to make tiny adjustments. It seems to me that depending on a rubber sleeve to perfectly align a mechanical device every time it is moved doesn't make sense.

I kept my skinny 500 sleeve in place as it allows me more movement than the wider sleeve would, and it still acts as a cushion if the table and power unit are slid together.

Re: 520 table not aligning

Posted: Fri Nov 19, 2021 12:41 am

by Mike907

Here's quite a thread on the spacer rings:

viewtopic.php?p=68229#p68229

Mike

Re: 520 table not aligning

Posted: Fri Nov 19, 2021 7:20 am

by dusty

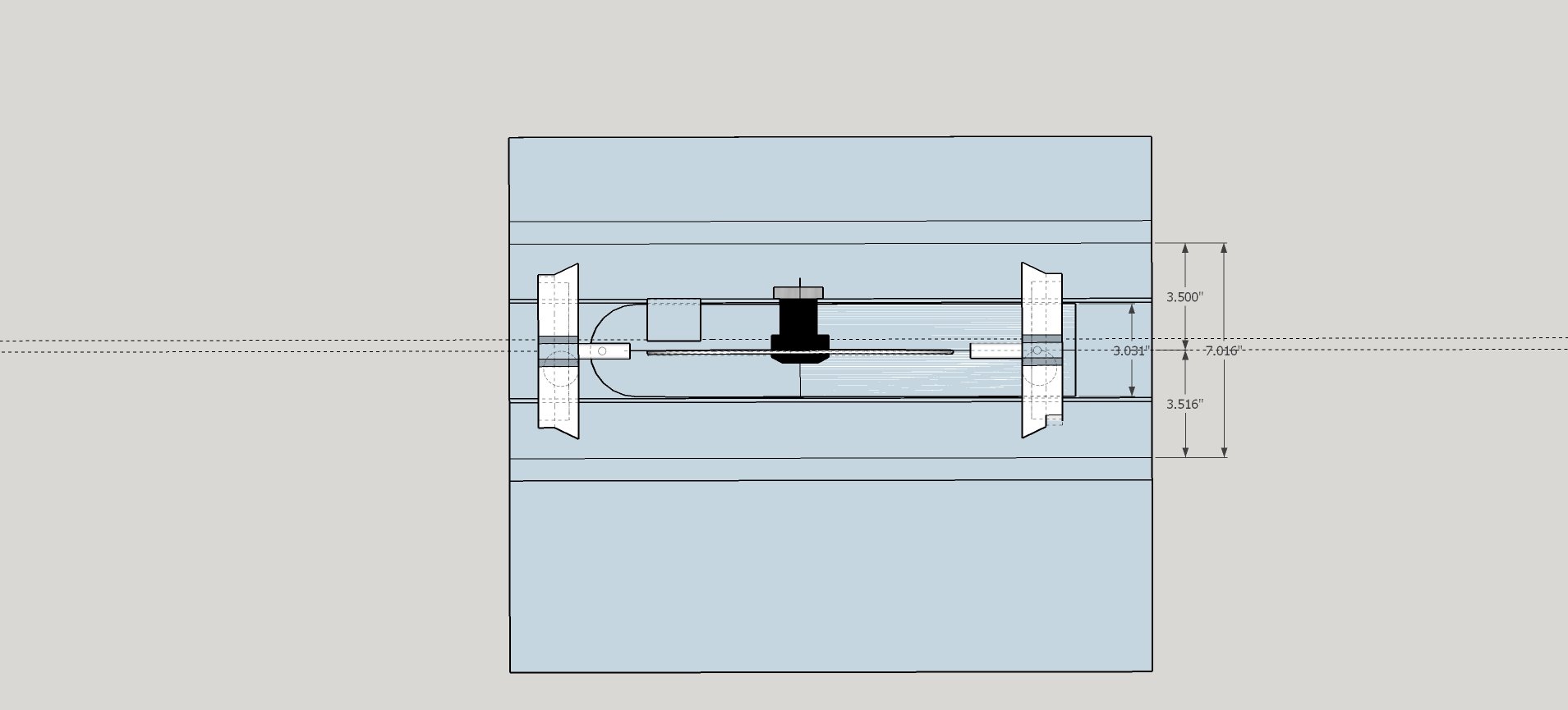

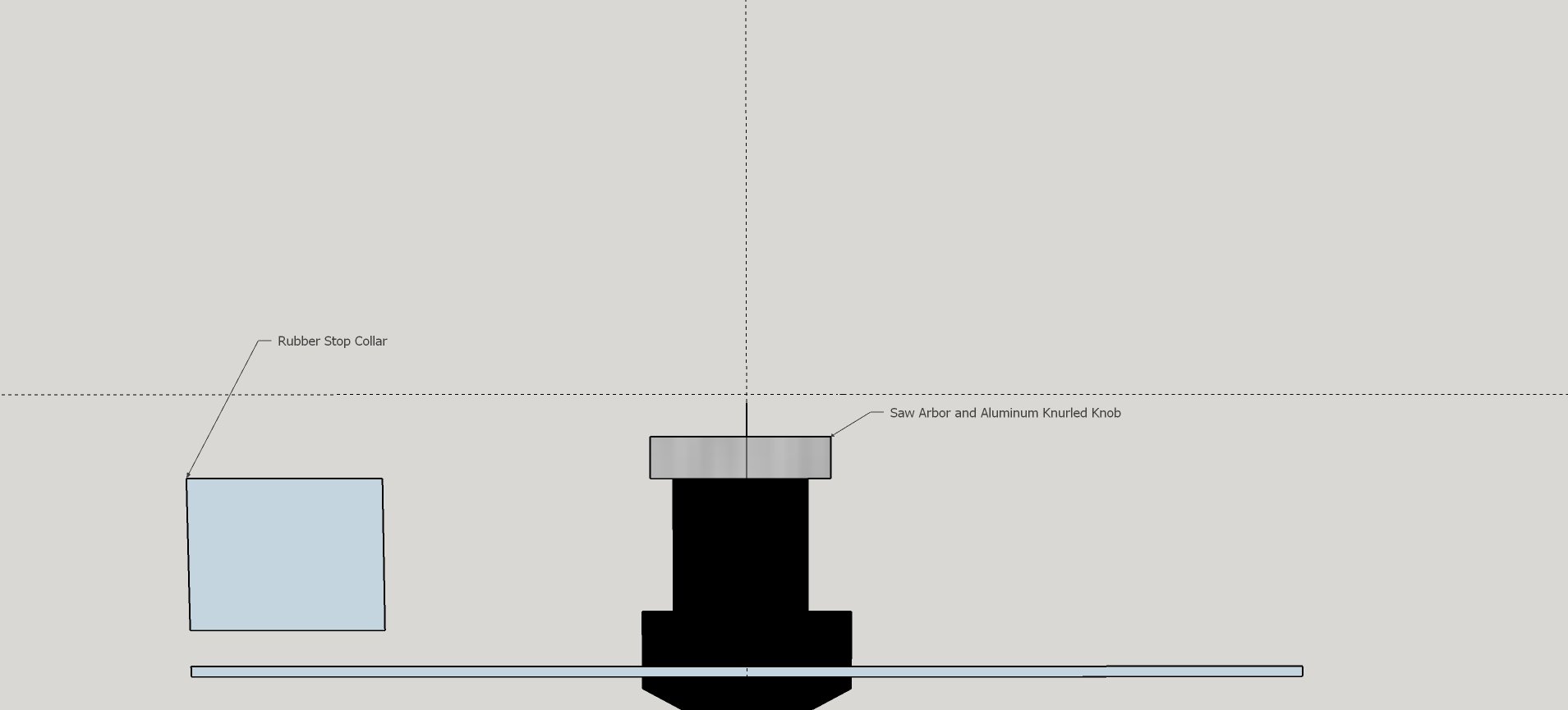

- Spindle and Carriage Brought Together.jpg (76.81 KiB) Viewed 1804 times

- Saw Blade and Arbor with Rubber Bumper.jpg (52.13 KiB) Viewed 1802 times

Not a problem as is. Use the quill or relocate the carriage to position the saw blade where you want it in the table cutout.

However, I contend that with the carriage and headstock slid together against the rubber bumper that the saw blade should be centered in the cutout. This is dependent on a proper rubber bumper and the quill fully retracted.

Also note the relationship (alignment of the table legs (left side)) with the saw blade and the saw blade with the aluminum knurled knob on the quill..

Re: 520 table not aligning

Posted: Fri Nov 19, 2021 9:01 am

by DLB

eagspoo wrote: ↑Thu Nov 18, 2021 10:05 pm

Hi, I have a 520 with a normal Mark V headstock

and a Power Pro headstock (long story).

I think it was set up for the Power Pro headstock which is currently being rebuilt. When I use the table saw with the Mark V headstock, I slide the table left until it hits the rubber sleeve on the waytube, lock things in place, lower the table, and... it looks like it is off by 1/8" or so. Everything really does work ok like this but wondering if I have the wrong rubber spacing sleeve?

You have the correct sleeve, there is no difference based on PowerPro Vs. Conventional headstock. The bumpers have been discussed in several other threads, my conclusion is that there has been wide variation in the dimensions of the bumpers, therefore, a wide range of normal. I have a bumper that produces much 'worse' (but acceptable) results than yours as well as one that gives a more centered relationship. You can order a new bumper from SS and see if you like it better, but IMO you are better off with the one you have. I prefer my blade centered with the quill slightly extended. Then if I want to make small adjustments for blade to fence distance in either direction I can use the quill to do it. This technique doesn't work with ZCIs, but IIRC it is discussed in PTWFE.

- David

Re: 520 table not aligning

Posted: Fri Nov 19, 2021 10:05 am

by wa2crk

If the blade does not hit anything and is close to to the center of the slot you are good to go. There are some variations due to the rubber ring being compressed due to age and use.

Bill V

Re: 520 table not aligning

Posted: Fri Nov 19, 2021 11:52 am

by chapmanruss

One question you asked that hasn't been addressed yet is the gap at the top of the sleeve. That is normal. The sleeve is cut square so the length is the same no mater how much it rotates around the way tube. The casting of the headstock is angled at the point the of the way tube openings. That angle of the headstock casting is what is causing the gap.

Re: 520 table not aligning

Posted: Mon Nov 22, 2021 3:28 pm

by edma194

You can replace the rubber sleeve with a piece of PVC pipe cut to a specific length that aligns well for you. I have that now on my 510, no particular length, and it's split so it can be installed it at any time, no need to remove the headstock. I first did this when I forgot to put the ring back on before installing the headstock. Now I have it on 2 machines and will probably do the same on my sanding shorty after I give it a final shortening, and any other machines I assemble. 1-1/2" PVC will fit tight on the way tube, 2" will hang loose.

Re: 520 table not aligning

Posted: Mon Nov 22, 2021 6:59 pm

by claimdude

+1 using the PVC. Works like a charm. Now when I slide the headstock against the table carriage blade is centered in the clearance plate.

Jack

Re: 520 table not aligning

Posted: Mon Nov 22, 2021 7:48 pm

by jsburger

Oh my, the rubber ring again. We have had this discussion in depth more than once over the years.

We will never know for sure what the SS intention was/is with this item. The original SS was the Model 10. It had a threaded post with a lock nut in the carriage that provided a stop against the head stock. Presumably so the default position of the carriage against the head stock would allow the table to be lowered so that the saw blade would pass through the insert slot without hitting the insert or table. That is what I think the intended purpose was. It certainly was not a head stock crash bumper.

Some will disagree but, that is what I think the rubber bumper is for also. Put on a saw blade, slide the carriage/table against the head stock and lower the table. You are insured the blade will pass through the insert.

Why should I care if the blade is not centered in the insert slot as long as it does not contact the insert? Yes, I know our logical mind says it should be centered but it makes no difference in every day operations. Also, since many of you here are obsessed with alignments within a few thou, how can a piece of rubber bumping up against imprecise rough castings achieve that?

The OP's picture of the "misalignment" will not affect anything.