Page 8 of 9

Re: Just bought a Shopsmith Mark V

Posted: Sat Jul 02, 2022 9:59 pm

by JPG

The motor.pan can be dropped away from the upper casting when in drill press position. ALL is then revealed from the open 'bottom'.

A bit tricky making the motor belt separate from the motor pulley, but relatively easy.

Magna did use(and likely still does) Model 10's for production drill presses.

Re: Just bought a Shopsmith Mark V

Posted: Sun Jul 03, 2022 12:31 am

by rpd

I was actually thinking a multi head drill press. but I found this reference to a 12-1/2" benchtop drill that Everett found a manual for, I had forgotten this one.

viewtopic.php?p=250645#p250645

Re: Just bought a Shopsmith Mark V

Posted: Sun Jul 03, 2022 8:14 am

by DaOldGuy

He is going to send me a photo of it, he did refer to is as Shop Smith and not Magna but I will share once I get the photo.

Re: Just bought a Shopsmith Mark V

Posted: Sun Jul 03, 2022 1:33 pm

by chapmanruss

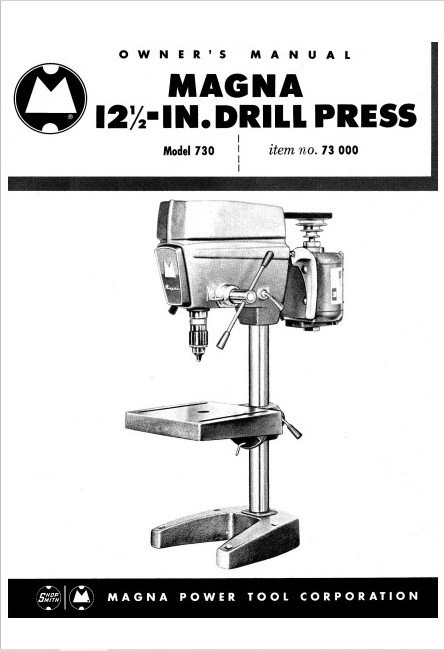

Below is a picture of the cover of the Manual for the Magna 12-1/2" Drill Press Model 730. It was part of the Magna Line tools which also included the Magna 9” Tilt Arbor Bench Saw, the Magna 12-1/2” Jig Saw, the Magna 30” Wood Lathe, the Magna 4” Belt Sander and the Magna 10” Contractors Saw. These tools were not as popular as the Shopsmith Mark 5 being made at the same time in the 1950's so few are ever found for sale.

_

- Magna Line Drill Press.jpg (42.54 KiB) Viewed 1026 times

.

This is a case in the confusion of the use of the names Magna and Shopsmith. Shopsmith originally was the name of the first 5 in 1 tool the Shopsmith Model 10E and was made by Magna Engineering Corporation. The Model 10ER followed and was later discontinued when the Shopsmith Mark 5 was introduced by Magna Engineering Corporation. Until Shopsmith Inc. was formed in 1972 to continue the tool line, Magna tools were a separate name from the Shopsmith Tools of the Model 10's and Mark series tools. Even the early SPT's which were called Add-a-Tools were Magna Tools not Shopsmith. Another reason for this name confusion is demonstrated on the cover of the Magna Drill Press shown above having the Shopsmith logo next to the Magna logo and their similarities.

Re: Just bought a Shopsmith Mark V

Posted: Sun Jul 03, 2022 9:30 pm

by DaOldGuy

I grabbed the manual from your link and I am going to send it to him to see if its a match.

Thanks for the info Russ

Re: Just bought a Shopsmith Mark V

Posted: Wed Jul 06, 2022 10:09 pm

by DaOldGuy

This fella helped me really understand the greenie since I work better off of visuals.

No videos posted for 8 months and his shop domain name has been parked, does not look like he is in business any longer maybe.

Poly V belt = Serpentine belt for a car guy like me 8)

He actually says if you have a new front bearing on the quill and new bearings on the drive sleeve, the quill will be solid.

https://www.youtube.com/watch?v=drv2C1lYtC4

Re: Just bought a Shopsmith Mark V

Posted: Thu Jul 07, 2022 2:21 pm

by chapmanruss

It is my understanding that Jacob Anderson has retired from servicing Shopsmith Tools.

The Statement

He actually says if you have a new front bearing on the quill and new bearings on the drive sleeve, the quill will be solid.

That could be true, but it would require a very snug fit between the splined end of the Quill Assembly going into the Drive Sleeve Assembly. A loose fit would create some wobble that would be carried out to the spindle end of the Quill. A double bearing Quill helps eliminate that wobble by creating a truer turning Spindle supported at two points inside the Quill Sleave. Using a double bearing Quill Assembly is more important in the Poly V Drive because of the use of part number 514083 called the Drive & Ring which is the nylon part attached to the end of the Drive Sleeve Assembly that actually has the mating splines for the Quill Assembly which can wear faster than the Gilmer Drive parts. The nylon cap was added to the end of the Drive Sleeve on later Gilmer Drive units to reduce noise. The splines are in the Drive Sleeve Assembly's metal Sleeve for the Gilmer Drive.

Re: Just bought a Shopsmith Mark V

Posted: Thu Jul 07, 2022 9:46 pm

by DaOldGuy

chapmanruss wrote: ↑Thu Jul 07, 2022 2:21 pm

It is my understanding that Jacob Anderson has retired from servicing Shopsmith Tools.

The Statement

He actually says if you have a new front bearing on the quill and new bearings on the drive sleeve, the quill will be solid.

That could be true, but it would require a very snug fit between the splined end of the Quill Assembly going into the Drive Sleeve Assembly. A loose fit would create some wobble that would be carried out to the spindle end of the Quill. A double bearing Quill helps eliminate that wobble by creating a truer turning Spindle supported at two points inside the Quill Sleave. Using a double bearing Quill Assembly is more important in the Poly V Drive because of the use of part number 514083 called the Drive & Ring which is the nylon part attached to the end of the Drive Sleeve Assembly that actually has the mating splines for the Quill Assembly which can wear faster than the Gilmer Drive parts. The nylon cap was added to the end of the Drive Sleeve on later Gilmer Drive units to reduce noise. The splines are in the Drive Sleeve Assembly's metal Sleeve for the Gilmer Drive.

I could see the mesh of the splines having gap would still have a bit of run out to your point.

I have been taking my Jointer apart and cleaning it up. The bearings are noisy. I am waiting for the Puller so I can Identify them enough to order some new Boca Bearings for it. I may also pull the drive sleeve and Quill bearings and order those too to test the theory.

I will also be ordering the upgrade parts as well so I have them if testing goes bad.

Re: Just bought a Shopsmith Mark V

Posted: Fri Jul 08, 2022 7:58 am

by DaOldGuy

Just thinking out loud.... If you added a 2 bearing Quill and there was play in the splines and or drive bearings, you could still have wobble / run out?

Re: Just bought a Shopsmith Mark V

Posted: Fri Jul 08, 2022 2:20 pm

by DLB

DaOldGuy wrote: ↑Fri Jul 08, 2022 7:58 am

Just thinking out loud.... If you added a 2 bearing Quill and there was play in the splines and or drive bearings, you could still have wobble / run out?

In my opinion if you have a good two bearing quill with all good parts it will exhibit very low runout. (Generally less than 0.001" in my experience.) Extreme error elsewhere may cause earlier failure of the quill bearings, but I think that is more hypothetical than real. And would likely present itself in some other way.

Woodshop Nerdery (youtube) reported on a new Mark 7 with what he felt was a bad from the factory quill:

https://www.youtube.com/watch?v=HEFFYw29yV4 So yes, it happens.

The current version quill that SS sells has a one piece spindle and larger bearings than the version Skip referred to in his video. I'm not suggesting it is necessarily or significantly better, these aren't the only changes. IIUC the current version has been around for 10+ years.

- David