Page 12 of 20

Re: Mark V Speed Control

Posted: Mon Aug 08, 2022 1:16 pm

by dusty

JPG wrote: ↑Mon Aug 08, 2022 10:05 am

You may observe that almost all 'discussions' involving trying to gain greater understanding of the beast will include the same participants roaming here. Not all come to the same conclusions however.

But all gain by their involvement.

Your observations are spot on but I have come to the conclusion that the different results are because we are not all using the same assumptions to start with.

How long is the belt

What is the diameter of the sheaves

Are calculations considering PD or not

Are all sheaves the same diameter

What is the condition of the belt

What is the condition of the sheaves face

What is the motor RPM (I have three and they are all different RPM (unloaded))

My tach:

https://www.amazon.com/AGPtek%C2%AE-Pro ... 1481&psc=1

Taker a speed reading. Rotate the speed dial 1 full revolution. Take a speed reading. Rotate back to where you started. Take a speed reading.

Do this at different points on the speed dial. Are you grinning or are you sorta in doubt about just what is happening.

Re: Mark V Speed Control

Posted: Mon Aug 08, 2022 6:07 pm

by dusty

DLB wrote: ↑Fri Aug 05, 2022 1:22 pm

dusty wrote: ↑Fri Aug 05, 2022 10:37 am

Dave

I need help that I hope you can provide. I am attempting to understand the differences between your numbers and mine. If you would do the following for me it would help me greatly in getting to the understanding.

What I would like to know is this:

With the speed dial set so that your idler shaft speed equals the motor speed (3587rpm) what does the speed dial read.

Why: Because I have been considering that as "Mid Range" at which time I expect the idler pulley and the motor pulley to be equal diameter. Measured with a tool similar to your use of a t-nut.

Mine measured 3574 RPM today at Idler = Motor, slightly lower motor RPM than when I collected data. Estimated 'K.6' slightly more than midpoint between K and L. Motor sheave rim to belt measured 0.76". I can't get a quality measurement on the Idler for belt depth, but presume it is equal.

- David

The spring changes in length by 1/2" for every 3/4" in belt depth. With a bit of arithmetic you can determine belt depth by measuring the spring. With that information you can calculate shaft speeds.

Re: Mark V Speed Control

Posted: Tue Aug 09, 2022 4:05 pm

by DLB

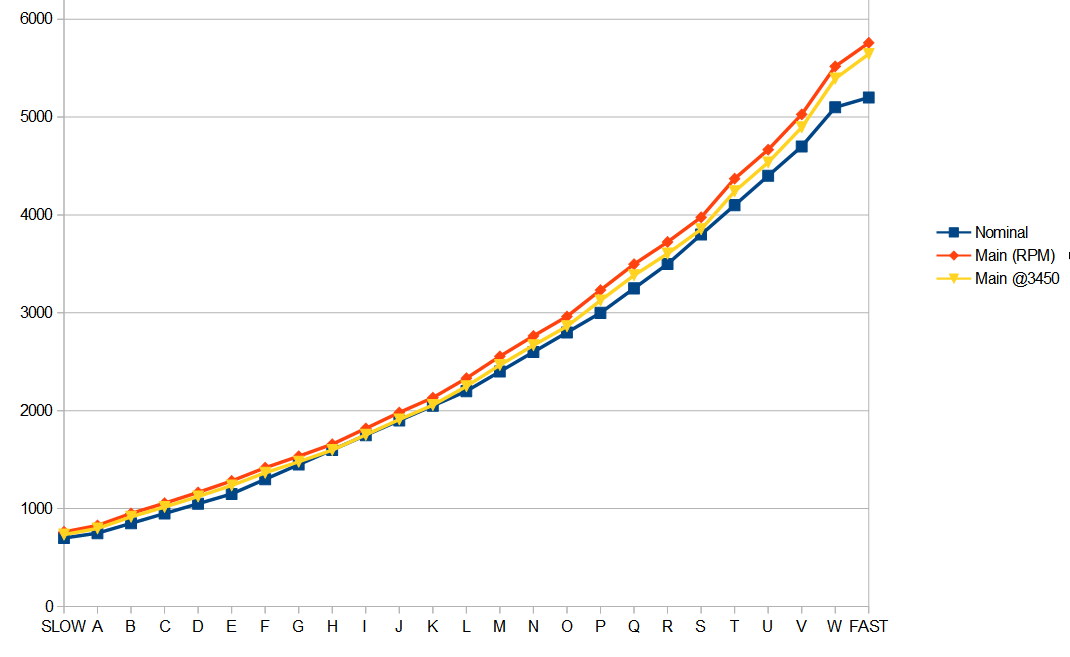

Here is a graph of the speed data I provided earlier:

- 520 Speed Chart.png (57.1 KiB) Viewed 925 times

Nominal is from the speed chart, Main (RPM) is measured, Main @3450 is projected speed at the full load speed of the motor. In this case I calibrated the speed dial at K using the tach, as opposed to the method used in high speed adjustment. In hindsight, K was not the best choice for minimizing error to nominal.

- David

Re: Mark V Speed Control

Posted: Tue Aug 09, 2022 4:14 pm

by dusty

DLB wrote: ↑Tue Aug 09, 2022 4:05 pm

Here is a graph of the speed data I provided earlier:

520 Speed Chart.png

Nominal is from the speed chart, Main (RPM) is measured, Main @3450 is projected speed at the full load speed of the motor. In this case I calibrated the speed dial at K using the tach, as opposed to the method used in high speed adjustment. In hindsight, K was not the best choice for minimizing error to nominal.

- David

Excellent.

Re: Mark V Speed Control

Posted: Wed Aug 10, 2022 8:17 am

by SteveMaryland

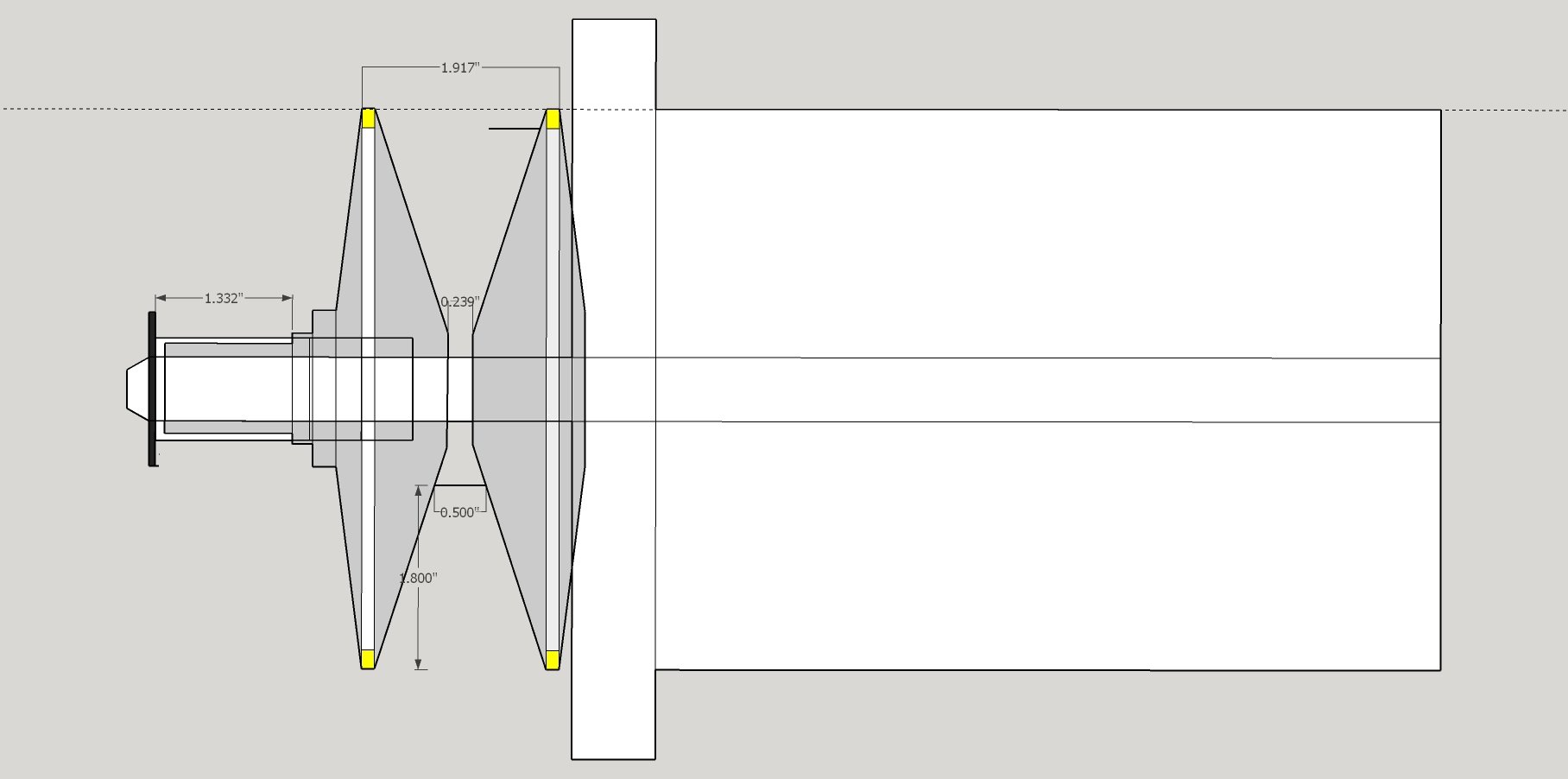

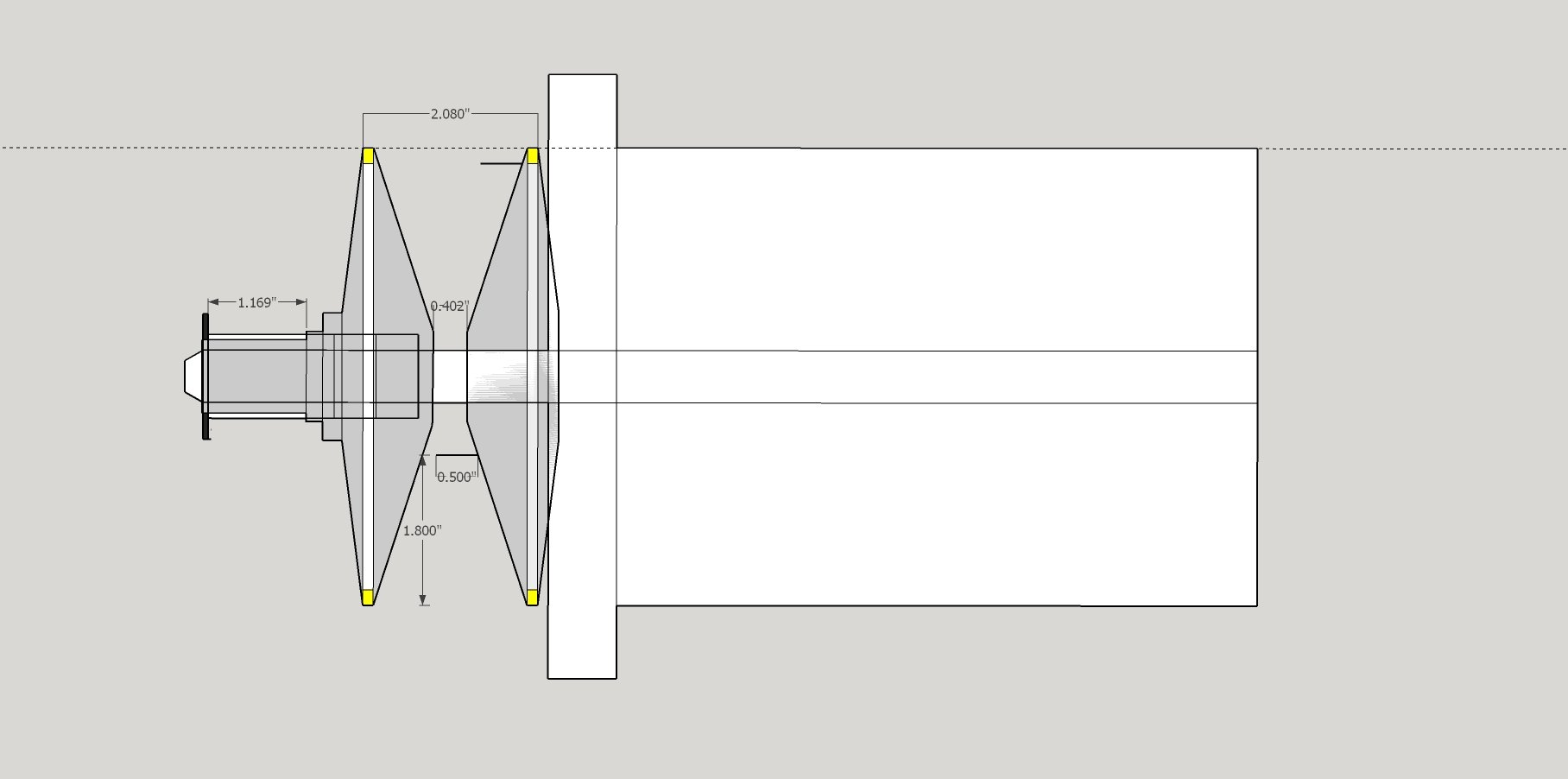

For those of us who are measuring geometry within the headstock, the attached drawing is supplied.

Shows what the drive geometry should look like, and measure, when running around 700 RPM and using the "Official Shopsmith Belt". All the circled dimensions should be measurable from within the case.

Note the "partial traction loss" of the belt. I think this condition is unavoidable if 700 is desired. A built-in Shopsmith design flaw in my opinion.

If 700 cannot be reached, it must be because something is blocking the drive from attaining the geometry shown. I have not measured my drive against this drawing nor have I measured actual speed.

postscript - the section view shown is looking toward the rear side of the headstock - opposite the operator side.

Re: Mark V Speed Control

Posted: Wed Aug 10, 2022 8:56 am

by dusty

SteveMaryland wrote: ↑Wed Aug 10, 2022 8:17 am

For those of us who are measuring geometry within the headstock, the attached drawing is supplied.

Shows what the drive geometry

should look like, and measure, when running around 700 RPM and using the "Official Shopsmith Belt". All the circled dimensions should be measurable from within the case.

Note the "partial traction loss" of the belt. I think this condition is unavoidable if 700 is desired. A built-in Shopsmith design flaw in my opinion.

Can't see why 700 cannot be attained unless something is blocking the drive from attaining the geometry shown. I have not measured my drive against this drawing nor have I measured actual speed.

Your drawings depict a lot of the same information that I have but one detail that you are missing is the prohibition imposed by the spring on the motor shaft. Once that spring becomes fully comprised further adjustment is impossible. On your drawing you show the distance separating the two sheaves to be 2.08". I believe that tyhe spring will limit that separation at about 1.71".

As I read your drawings, I also believe that the belt will have been pulled into that area where the belt becomes seized. Further adjustment is impossible and you are now required to retrieve the belt from the crevice.

Inconsequential mislabel: Fixed Position Motor Sheave

Re: Mark V Speed Control

Posted: Wed Aug 10, 2022 9:50 am

by SteveMaryland

If the motor spring will not let that dimension get to 2.08, then that should explain why people cannot get to 700. Mystery solved?

As for the belt dropping inbetween the sheaves on the low speed end, I think that could happen but only for a narrow or worn belt (the belt width shown is a full .59" (15mm officially)), others say their actual width is narrower. And no belt would fall in if that 1.71" limitation is real. At least on the low end of the speed range. Maybe on the high end a jam could still happen (on paper), but a high-speed jam would be very unwelcome. another reason to stay away from the high speed end.

Cutting a few coils off of the motor spring would partially fix the low speed problem but would also reduce the spring force when extended to the point that the highest speeds could not be attained. An improvement? I think most users would rather have a lower min speed even at the cost of lower max speed.

So how can Shopsmith keep claiming 700? Maybe long ago they could get to 700, but subsequent design changes to spring, belt, dial etc. now prevent it.

Re: Mark V Speed Control

Posted: Wed Aug 10, 2022 10:49 am

by dusty

SteveMaryland wrote: ↑Wed Aug 10, 2022 9:50 am

If the motor spring will not let that dimension get to 2.08, then that should explain why people cannot get to 700. Mystery solved?

As for the belt dropping inbetween the sheaves on the low speed end, I think that could happen but only for a narrow or worn belt (the belt width shown is a full .59" (15mm officially)), others say their actual width is narrower. And no belt would fall in if that 1.71" limitation is real. At least on the low end of the speed range. Maybe on the high end a jam could still happen (on paper), but a high-speed jam would be very unwelcome. another reason to stay away from the high speed end.

Cutting a few coils off of the motor spring would partially fix the low speed problem but would also reduce the spring force when extended to the point that the highest speeds could not be attained. An improvement? I think most users would rather have a lower min speed even at the cost of lower max speed.

So how can Shopsmith keep claiming 700? Maybe long ago they could get to 700, but subsequent design changes to spring, belt, dial etc. now prevent it.

We agree in principal but our drawings differ in detail and thus in the numbers. Notice in view two that the left end of the floating sheave is approaching the washer which would be a hard stop (before your numbers are achieved).

There ares ome hard stops in the design even though they are not discussed in Shopsmith documentation.

- Study of Sheave Movement, Fan and Floating View 2.jpg (73.78 KiB) Viewed 855 times

- Study of Sheave Movement, Fan and Floating.jpg (65.59 KiB) Viewed 855 times

Re: Mark V Speed Control

Posted: Wed Aug 10, 2022 1:48 pm

by DLB

The 2.08" Vs 1.71" dimension: It isn't easy to measure accurately with tools I own due to close proximity of the fan shroud, but I see it as greater than 1-7/8" and less than 1-15/16". I'm pretty much in the middle of your two numbers. Spring appears to be fully compressed. I measured two machines. with a tape measure. If I needed to measure this accurately I would measure each sheave to the fan plate, but measuring that for the fan sheave would require some disassembly for access.

The more critical 1.80" dimension on Steve's drawing is not achieved on either of my machines. 1.746" measured on one, slightly less on the other. Using the gauge I made and translating with calipers. On the other hand, my belt is riding higher in the Idler sheaves on both machines, very slightly proud of the pulley. So there is some offset, both of my PDs would be larger than shown in Steve's drawing whether I used his estimate or mine of datum line to outer belt.

Note - I think my measured data indicates the 1.6 Idler/Main ratio is correct but rounded off. I averaged 1.573 over 20+ measurements.

- David

Re: Mark V Speed Control

Posted: Thu Aug 11, 2022 2:41 pm

by dusty

After seeing your chart, Dave, I decided to plot my data. I had not done so even though I feel that there is something amiss with my Mark V.

The High Speed Stop has been set and the Speed Dial properly positioned (I think). The motor in this Mark V runs at 5480 rpm as it came from Shopsmith moons ago. I hardly ever operate on the upper end but when up there the machine does not feel/sound right.

Column "B" is the Main Drive. When the Main Drive is at Motor Speed (3580 rpm) the speed dial is between K and L.

Please ignore the numbers on the left side of the graph. They do not correlate with the graphed data.

- My Mark V Spoeed Chart.png (82.28 KiB) Viewed 753 times