Page 1 of 2

Stumpy Nubs Dual Drum Sander on Shopsmith

Posted: Wed Sep 11, 2024 9:11 am

by cooch366

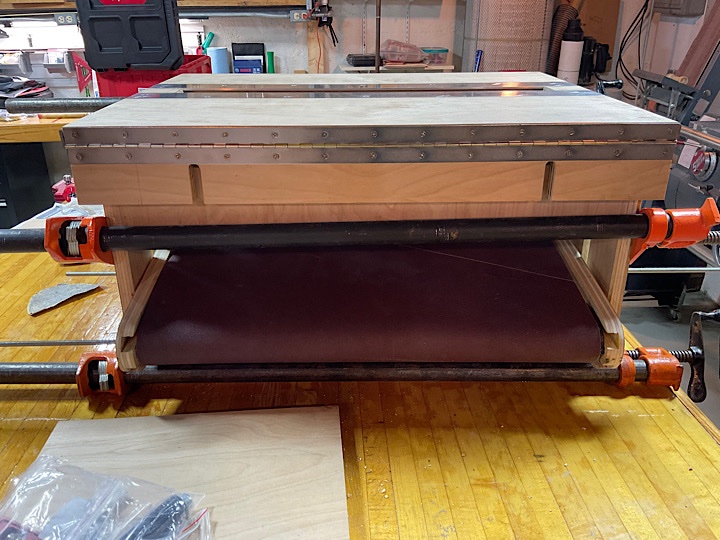

I purchased Stumpy Nubs plans for the Dual Stage Drum Sander with the thinking & hope to adapt it on a Shopsmith.

I’ve been working on it and have gotten to the point where I actually think it is going to work. I have the outer shell, top and feed table workable to the point to share. It’s been trial & error but no major issues or setbacks (yet, fingers crossed). I’m waiting for the feed table belt to arrive to finish that, and then will look at assembling the outer shell.

It looks like I’ll have between 3” & 4” as a maximum thickness which is fine for what I’m going to use it for. I’m using a live center, with the outer case wedged between the headstock & right tie bar. I was able to fit the outer shell around the carriage, only losing 1/2” in height from the tubes. I had to modify the right side of the drum (after I had it completed) to add a 2” x 2 1/2” extension to allow clearance for the outer case & drum to be able to reach the live center. You can see that I cut the right side of the outer case to fit the 4” drum, when it only needed to be 2 1/2 ish for the diameter of the extension. I may make a new right side outer shell piece (I’m thinking dust collection).

On to the next phases.

- IMG_1044.jpeg (152.14 KiB) Viewed 18453 times

- IMG_1043.jpeg (140.09 KiB) Viewed 18453 times

- IMG_1042.jpeg (161.26 KiB) Viewed 18453 times

Re: Stumpy Nubs Dual Drum Sander on Shopsmith

Posted: Wed Sep 11, 2024 9:59 am

by BigKahunaFL

Great job! I'm following along your adventure with GREAT interest as I too, am planning to do this. I haven't started fabricating it but have purchased the plans and begun "engineering" a solid model of it, to "hopefully" work out any kinks in the plan.

Today’s progress

Posted: Wed Sep 11, 2024 6:07 pm

by cooch366

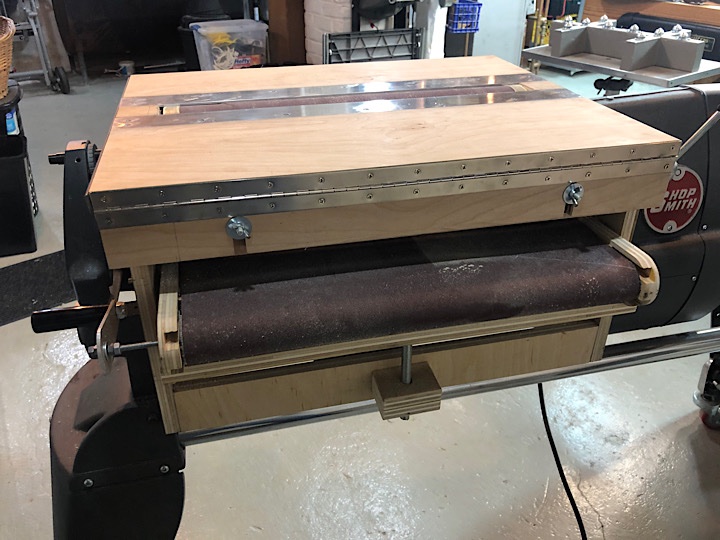

Was able to install the feed table belt and complete it, also finish case access holes and threaded rod install.

I did have an issue with the belt not fitting. I used the cut list provided in the plans however the table was too long and the belt would not fit. I got around it by trimming 3” off each of the 2 table half’s. I don’t know if I messed up or what. But it’s all good.

- IMG_1049.jpeg (173.02 KiB) Viewed 18300 times

- IMG_1048.jpeg (179.93 KiB) Viewed 18300 times

A little more progress

Posted: Sun Sep 15, 2024 6:34 pm

by cooch366

Just an FYI and heads up, the pictures in the plans do not match the cut list as you can see in the next 2 pictures. The upper table support in the plans picture is shorter than the part on the cut list. Not a big deal but I guessed at where to place the hanger bolts, and had to notch it to fit over the angle iron. I also could have cut it shorter, but went with the cut list dimensions.

- IMG_1066.jpeg (133.58 KiB) Viewed 17286 times

- IMG_1065.jpeg (153.1 KiB) Viewed 17286 times

I fabricated a belt crank from some of the leftover aluminum stock and handles from Amazon. I’ll cut the threaded rod after the case is permanently assembled.

- IMG_1064.jpeg (183.73 KiB) Viewed 17286 times

Complete except for sandpaper on drum

Posted: Wed Sep 25, 2024 2:13 pm

by cooch366

Re: Stumpy Nubs Dual Drum Sander on Shopsmith

Posted: Wed Sep 25, 2024 8:15 pm

by BuckeyeDennis

Well shoot, if for some reason it doesn’t work well, you could probably still fetch a good price for it as an “industrial decor” end table or whatnot. It looks

great.

Re: Stumpy Nubs Dual Drum Sander on Shopsmith

Posted: Thu Sep 26, 2024 4:17 pm

by algale

Looks great, hope the results are equal!

Almost there…. But need some tweaks

Posted: Mon Sep 30, 2024 8:57 am

by cooch366

Almost complete, but after attaching the sandpaper (which was one of the more challenging tasks of the build) It became apparent that without a way to adjust the drum and the feed table (for parallel) I was not as diligent as I should have been in balancing the drum. It needs to be tweaked (sanded) to make it parallel to the feed table. So I’ll have to remove the sandpaper and redo the balancing.

Also I’ll need to figure out something the to attach the ends of the sandpaper to the drum. Temporarily I just inserted a small wood screw to hold it for now until a better solution is found. Any ideas or suggestions would be appreciated.

- IMG_1120.jpeg (130.39 KiB) Viewed 15919 times

I also added threaded inserts to the bottom of the case so I could add my planer clamps. I found that even thought I wedged the case between the headstock and the tail stock, when lifting the table it was a little top heavy and tilted easily. The clamps fixed the issue and works great.

- IMG_1122.jpeg (115.45 KiB) Viewed 15919 times

Not easy to see, but this is the tweaking that is needed.

- IMG_1121.jpeg (147.01 KiB) Viewed 15919 times

Complete (for now)

Posted: Fri Oct 18, 2024 10:59 am

by cooch366

So I finally got back to this, and tested it out. I’m going to say it was a successful build. I haven’t put it thru a big workout yet, but I’m pleased with the results.

A couple of possible modifications (depending on how much use it gets),

- Dust collection. I did not put any into the case. I’m hoping my collection system with hood works, if not I may need to address installation of some sort of additional collection help in the case.

- Sanding drum. I only made 1 drum (120 grit paper to start is installed). Getting the sandpaper installed is a challenge, depending on use, I may try installing a hook & loop system on it, and hopefully that will make it a little easier.

- IMG_2024-10-18-103941.jpeg (134.87 KiB) Viewed 15061 times

- IMG_1136.jpeg (128.52 KiB) Viewed 15061 times

- IMG_1137.jpeg (150.51 KiB) Viewed 15061 times

Re: Stumpy Nubs Dual Drum Sander on Shopsmith

Posted: Fri Oct 18, 2024 12:05 pm

by edma194

I like it! Did you consider using a leg in the carriage to to raise and lower the front conveyer belt drum? Or 2 legs to move the entire assembly up and down? You can use legs from a lathe tool rest or from any model main table.

You can buy a lathe tool rest leg for $80 from Shopsmith. For $90 you can get a whole Model 500 tie bar assembly with 2 legs if you wanted to raise the entire assembly up and down instead of just tilting it. And you can do much better than that buying the parts from eBay. For the limited space you have under the drum you might need to cut down the tops of the legs.

How easy is it to change drums? I think I'd want at least 2 for fine and coarse grits.