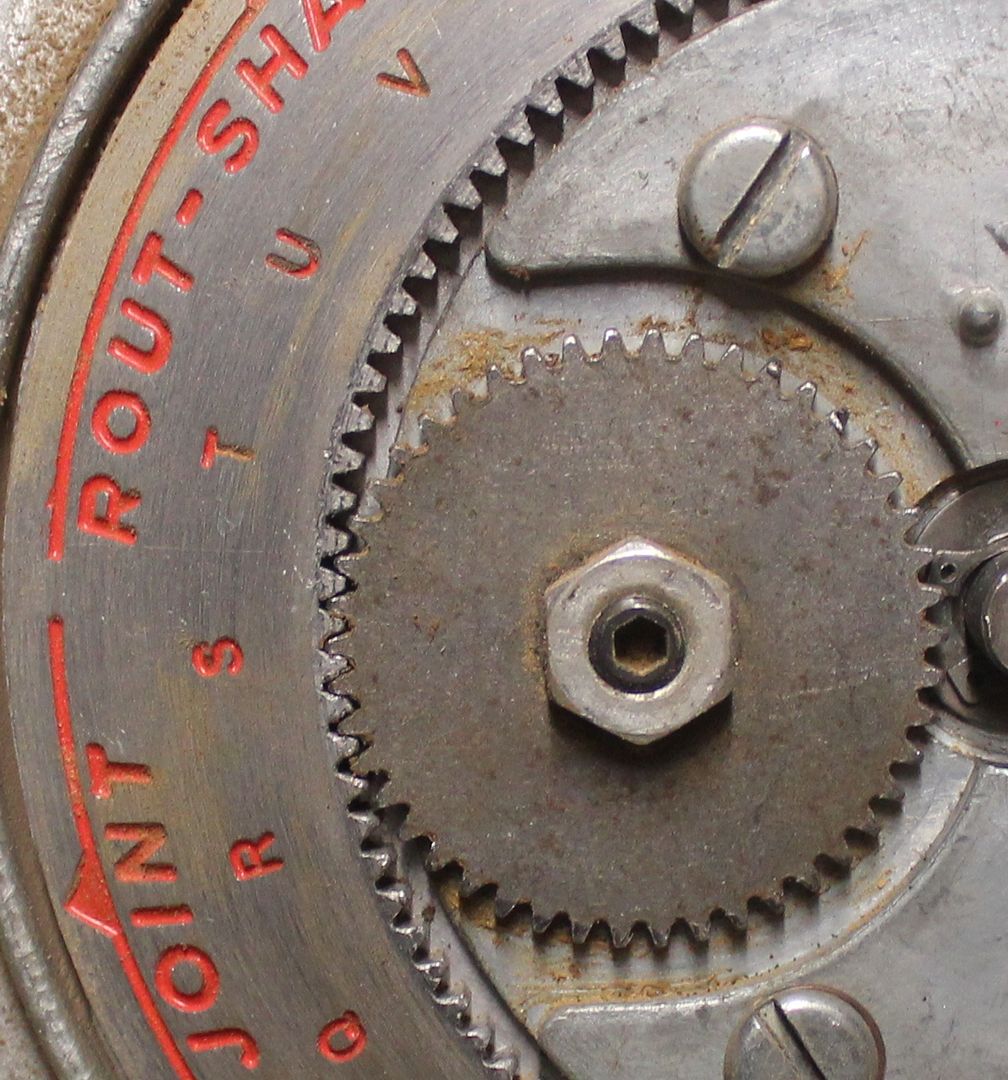

Greenie Mark 5

Gilmer drive

The knob(with stripped teeth) can be repaired better than new. *

http://www.ebay.com/itm/Shopsmith-MARK- ... SwhcJWJCpk

The outer dial does nothing except rotate as an indicator.

The shaft the knob attaches to actually moves the internal quadrant gear(porkchop) to move the control sheave that alters the speed.

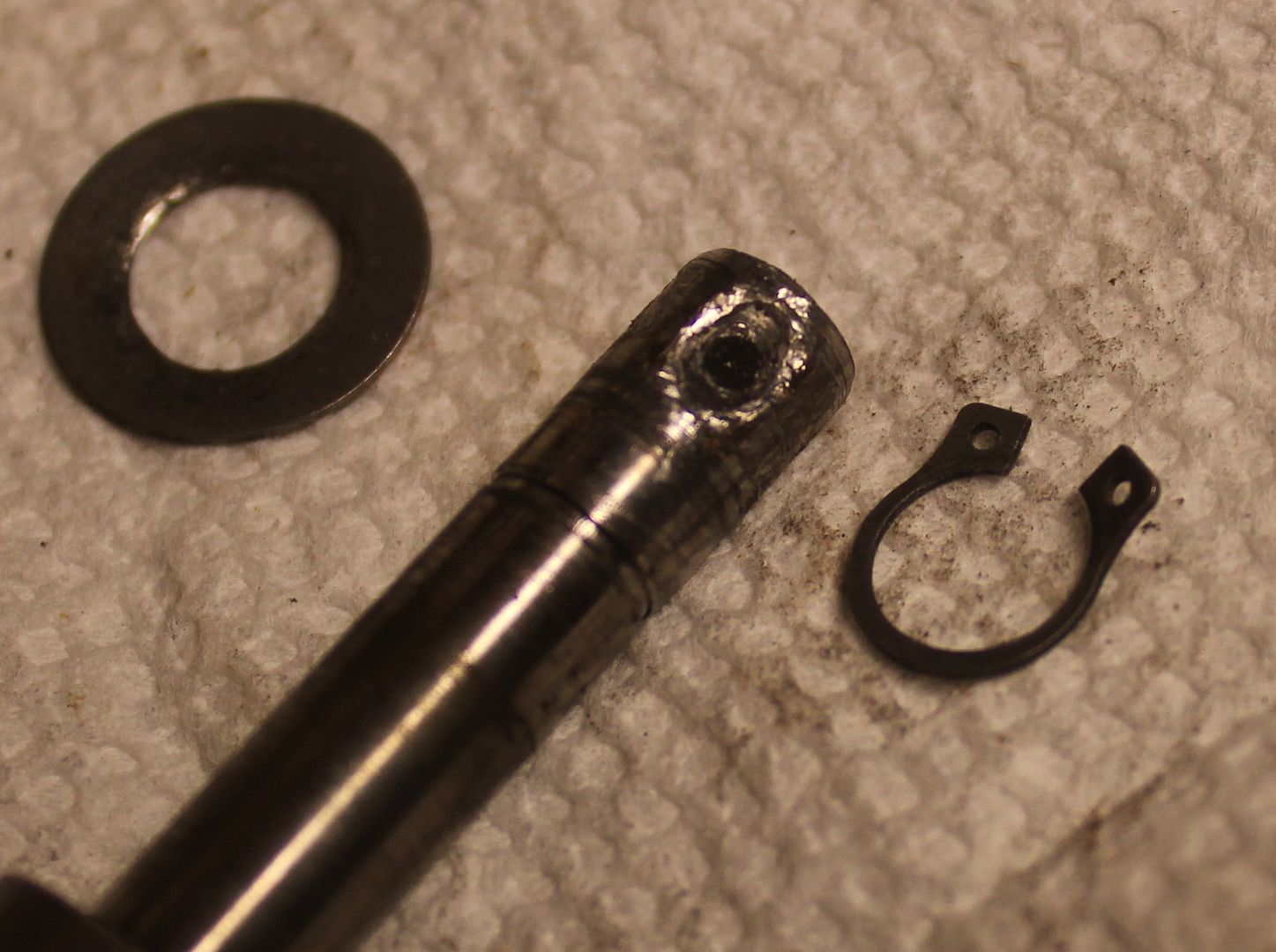

I assume you discovered the set screw that retains the knob to the shaft.

Do NOT turn the knob unless the internal pulleys re rotating(under power or manually).

Excellent condition(other than the knob teeth). I think the idler gear is usable.

* The choice is yours re the knob, but if you request it, 'grany' will return 'yours'(it will add turn around time) or get a new one from SS. IMHO the repaired knob with steel gear teeth is superior.

'next', remove the speed control(three screws and the clip from the control sheave to the porkchop) and take a pix of the teeth on the porkchop. Make sure the small spring under the outer dial does not 'disappear'.