dusty wrote: . . .

Now I don't know what to do.

Just ignore the 'Naysayers'!:D

Moderator: admin

dusty wrote: . . .

Now I don't know what to do.

Si Senõr! They were not 'naying' all the time!dusty wrote:These folks are not natsayers. They are people with good, constructive comments and space balls. Capisce ?

If my brain is working right (and there is absolutely NO GAURANTEE there!!), reducing the stile thickess will not move the stiles closer together. That's a function of the 1/2" laps on the ends of the rails. Sketch out a top view and you'll see what I mean. I'll look at it closer at noon.heathicus wrote:Back to the task at hand. I didn't ......

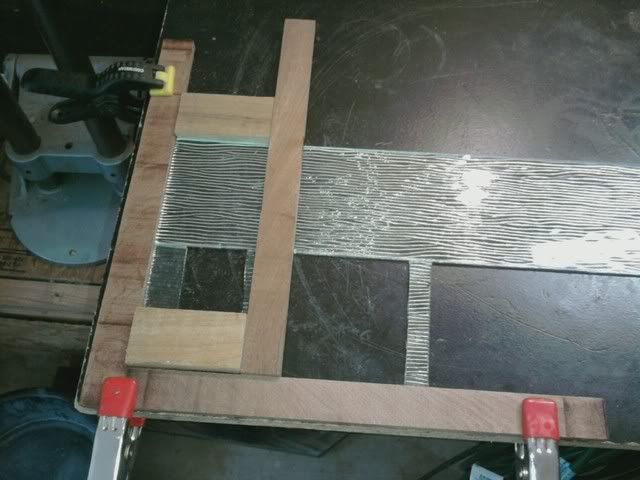

If I had the glass before cutting my stiles to width, I might have been able to check this and make the stiles a little wider to compensate. But I just don't like this fit. There's just too little overlap on one side of the glass and I fear it would come out too easy and make assembly difficult. So what I did was run the stiles through my planer again taking off about 1/16" from the thickness (leaving the width alone). This allowed me to move the stiles closer together giving me more room for the glass to overlap the stile. In the image below, all I did was make the adjacent mating stiles a little thinner, then move everything back together to fit, just as I did with the real wood.

[ATTACH]8834[/ATTACH]

Another point for the "having the glass first" argument. I can't make the glass thinner. I don't even want to think about trying to shave 1/16" off the width of the glass. But so far, I've been successfully working the wood to fit the glass instead of working the glass to fit the wood.

The outside to outside measurement of the the stiles are dictated by the the thickness of the mating stiles, plus the width of the glass, plus the thickness of the glass on the adjacent side. The rail lengths (and their joints) should be cut to fit that measurement. The glass can't be made thinner or narrower (well, it could be, but with more difficulty). So the only measurement that can be adjusted is the thickness of the mating stiles.mickyd wrote:If my brain is working right (and there is absolutely NO GAURANTEE there!!), reducing the stile thickess will not move the stiles closer together. That's a function of the 1/2" laps on the ends of the rails. Sketch out a top view and you'll see what I mean. I'll look at it closer at noon.

I barely had 1/16" of the glass past the stile edge. After taking a smidgen over 1/16" off the thickness of the stiles, I had right at 3/16".mickyd wrote:Also, made to spec, the glass should extend past the stile edges by 3/16" which is plenty.