I was fortunate to get my hands on four of these. I am attempting here to describe how to make use of them.

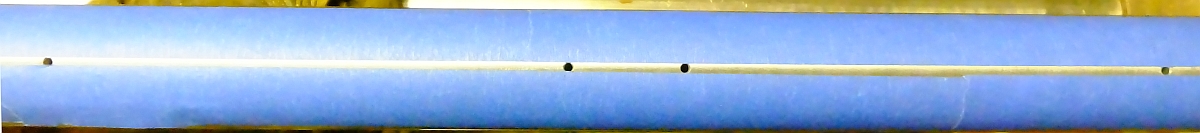

First step is to establish the location of the center for the new holes to be drilled in the way tube. By laying tape against the original rivet holes the center can be approximated.

- tape hole layout.jpg (108.17 KiB) Viewed 7829 times

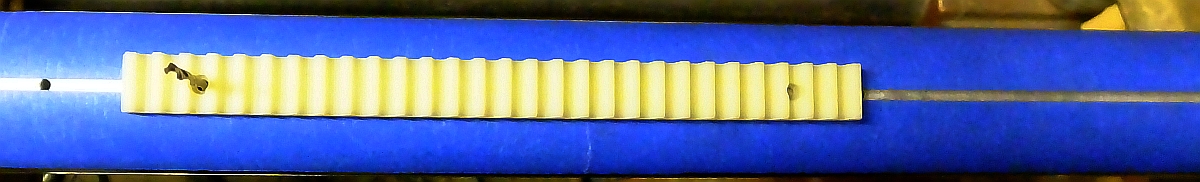

The original rack consisted of THREE pieces secured by TWO rivets each. The new rack pieces are half as long and are secured by two rivets each. One end of each new rack piece is to be riveted in the original holes at the end of the original rack pieces. Two new holes need be drilled for a rivet on both sides away from the original center hole to rivet the new rack pieces in place.

So align one new rack piece using a 0.120 drill bit by using one of the end holes securing the original piece. Then mark the location of the other hole centered between the two tape edges.

- align 1.jpg (177.01 KiB) Viewed 7829 times

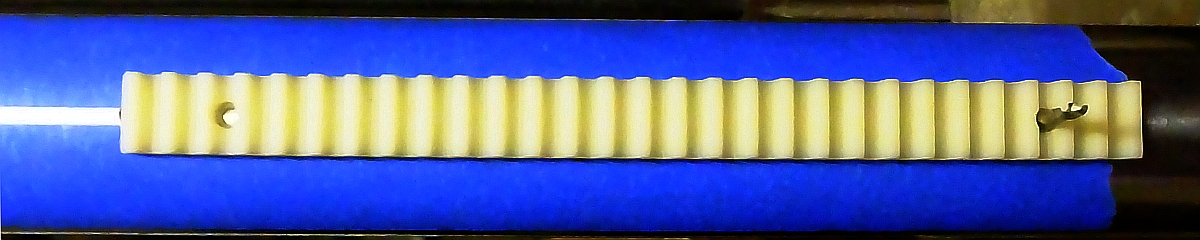

Repeat for the other 'half'.

- align 2.jpg (220.49 KiB) Viewed 7829 times

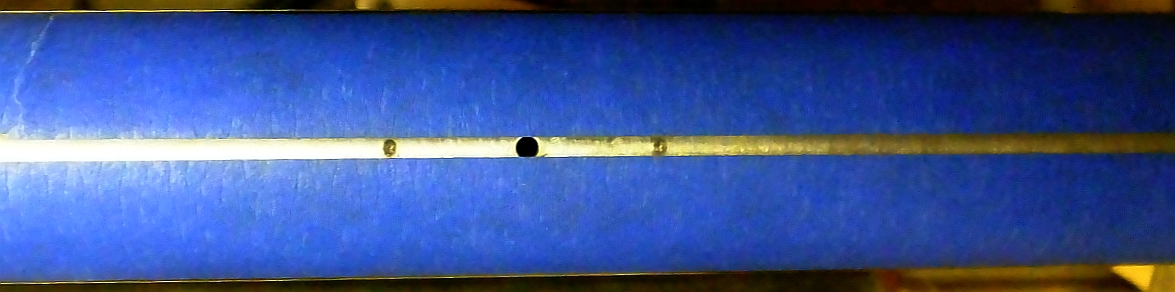

You should have a mark on both sides away from the original center rivet hole. Carefully dimple each location with a center punch. Since the way tube is round, care must be exercised to make sure the dimple is properly located. I find that progressively deeper small 'licks' will allow one to shift the location as the dimple is gradually made deeper.

- 1,2 marked.jpg (237.38 KiB) Viewed 7829 times

Repeat for the other 'half'.

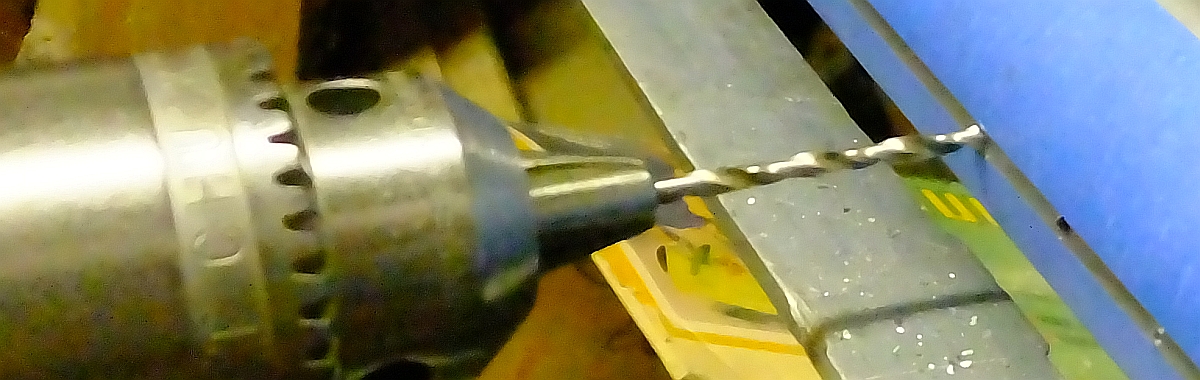

Now for the dicey part. I located the table top 7/8" below the drill bit center. Then used the rip fence to back up the way tube. I manually positioned the way tube horizontally to place the dimple directly in line with the drill bit. I used the smallest bit the chuck would securely hold to drill a pilot hole. It is quite easy to break a bit unless you hold it all very tightly. I find that clamping does not allow me to make minute position adjustments. The drill bit will let you know the way tube needs tweaking without breaking. A product of much practice.

- pilot hole.jpg (307.47 KiB) Viewed 7821 times

Repeat with a 1/8" bit. I originally drilled 0.120 holes, but could not locate any pop rivets of the original size(3mm I believe). So eventually the holes were enlarged to 1/8"(manually).

- final size.jpg (343.22 KiB) Viewed 7821 times

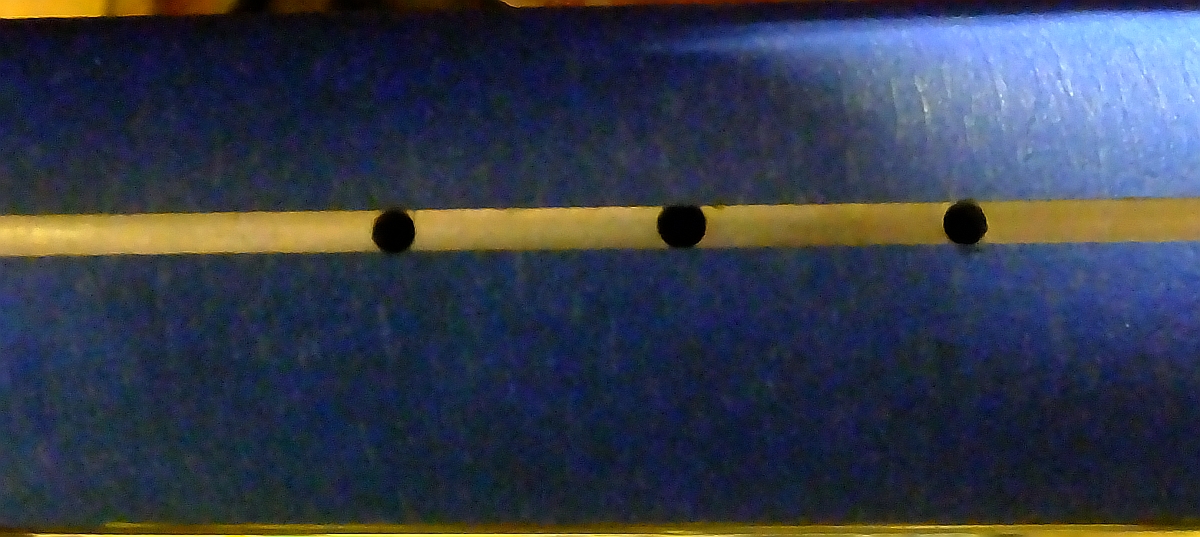

Holes drilled

- 1,2 drilled.jpg (461.7 KiB) Viewed 7821 times

Repeat (again).

As just mentioned pop rivets like the originals(I have never ever seen them elsewhere). The closest I could locate were supposedly 3mm(also 1/8"????) but measured 0.122" (3.09mm) so I bit the bullet and enlarged the holes. The new rack pieces needed to be enlarged also.

I feel steel rivets are preferable to aluminum ones but that leads to additional procurement issues. I found these at Lowes.

- POP RIVETS.jpg (880.44 KiB) Viewed 7821 times

The grip range is a bit excessive, but they were available.

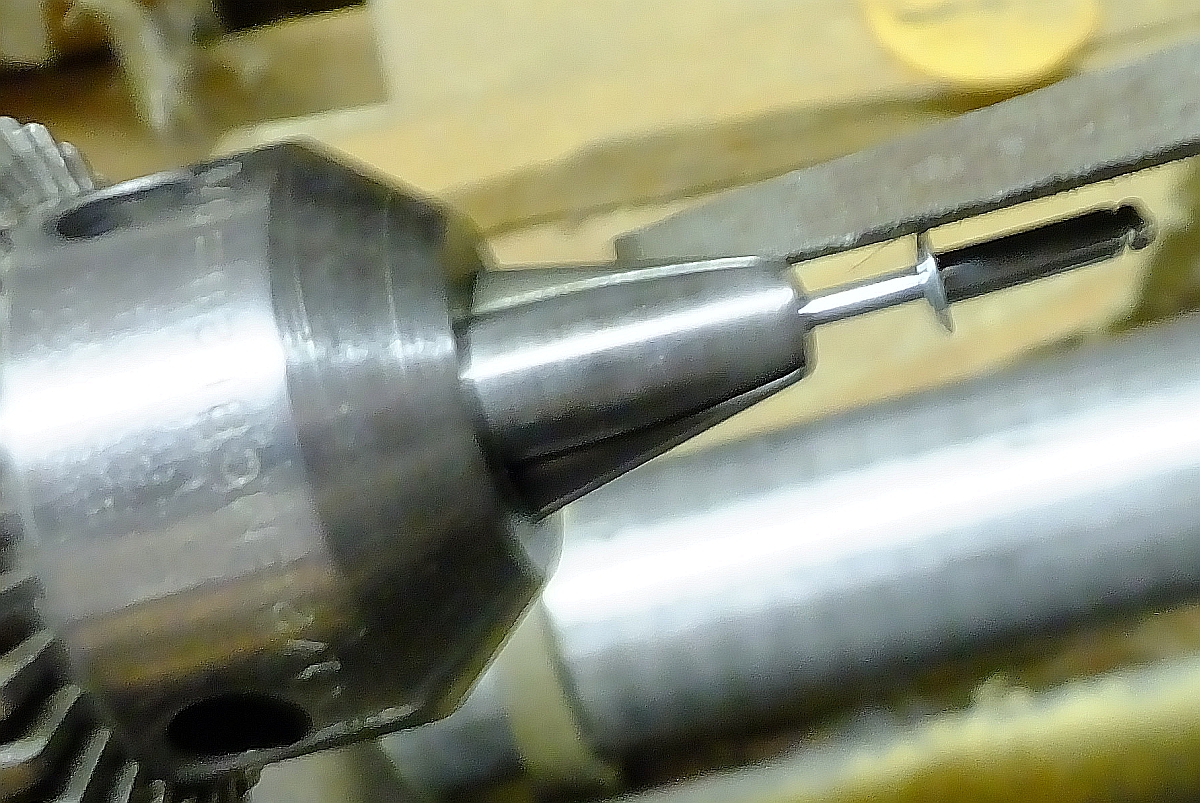

Now for the other shoe. The pop rivet heads are 1/4" od and the new piece holes are 0.200(matches the original(again)). So, they need to be 'resized'(fancy word for filed down). Slow with frequent measuring will get them down to 0.198 to 0.200".

- RESIZE RIVET HEAD.jpg (760.01 KiB) Viewed 7821 times

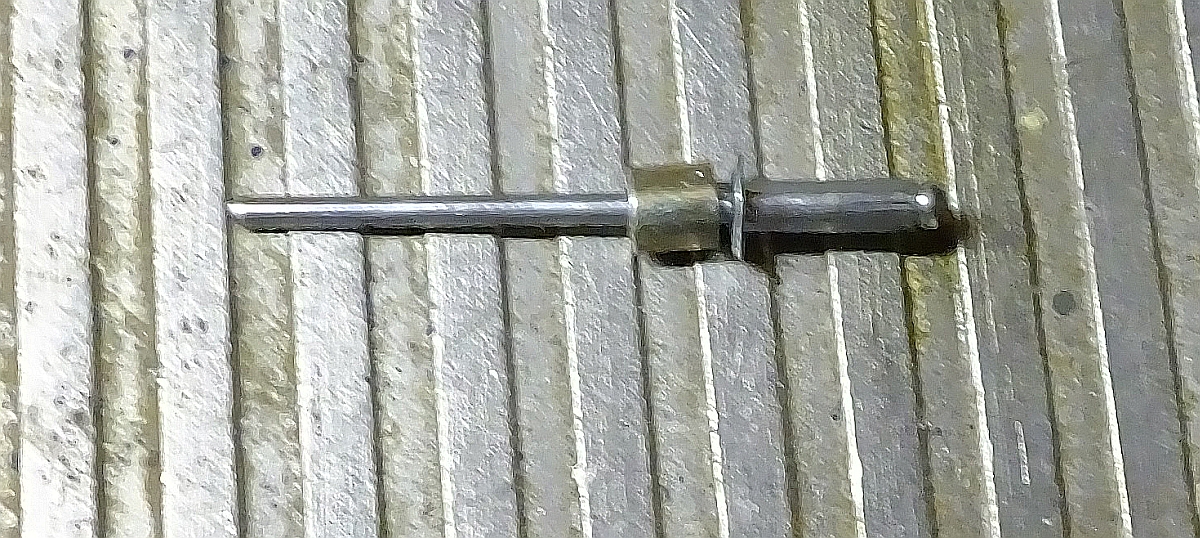

Moving on the the next 'issue' is the rivet head must be recessed into the rack. So a spacer is needed that will fit into the rack 'counterbore' and longer than the bore is deep.

From the miscellaneous jun. . parts jar.

- RIVET SPACER.jpg (615.9 KiB) Viewed 7821 times