Page 3 of 9

Re: New Shopsmith Owner

Posted: Thu Oct 05, 2023 10:22 am

by Restore

Thanks, I ordered the Guard & Splitter mount from Ebay...I did notice the ones listed for a Mark 5 model looked more like a real Riving Knife not just a Bracket/Splitter....Thinking once I have a dedicated hobby shop setup adding a more modern SS would be nice but I could never let this one go.

Re: New Shopsmith Owner

Posted: Thu Oct 05, 2023 1:45 pm

by chapmanruss

Restore,

I understand how you feel about this Model 10ER you are restoring. After getting my Father-in-laws Mark V 520 I learned a lot about Shopsmith tools and their history. I purchased Shopsmith Model 10ER S/N R64000 and restored it. I was hooked and have restored 2 dozen Model 10's, some Mark 5/V's, a Mark 2 and assorted tools and SPT's. Although most of those restorations have been sold, I have kept that first Shopsmith I restored.

I had the same problem you have when doing one of my Model 10 restorations. No Splitter but had the Blade Guard. Just like John said

The blade guard and bracket show up from time to time on eBay. Not sure if I have ever seen just the bracket.

so I made one. The PDF below is the pattern I created and used to make a replacement Splitter.

_

.

Although there have been three versions of the Splitter made for the Model 10 this one is the correct one for the Model 10ER's. The one I made is shown in the picture below (left) with an OEM version three Splitter (right).

_

- 103-35 V3 - custom left - original right.jpg (242.64 KiB) Viewed 2675 times

.

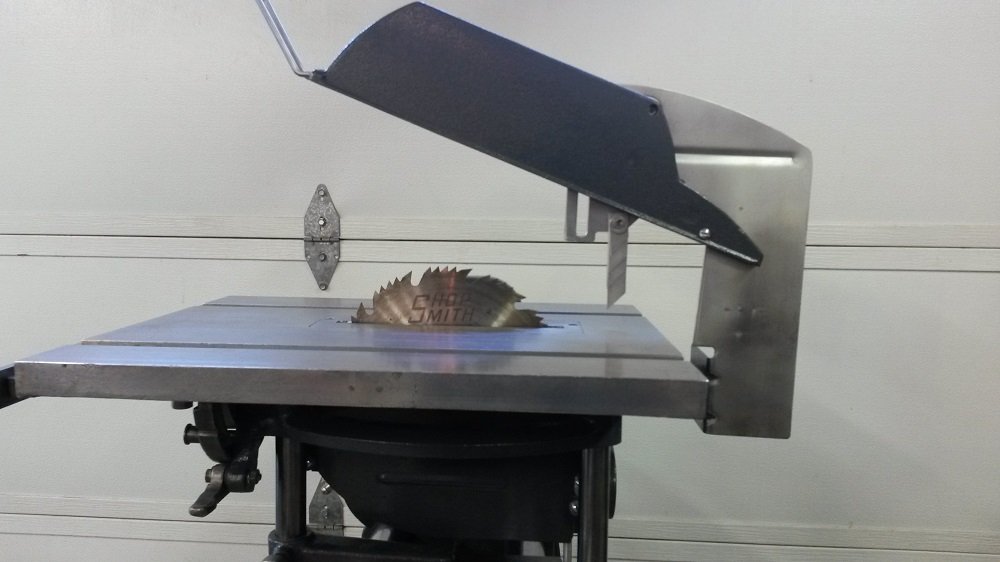

There is another option for the upper Blade Guard for Model 10's. The Upper (505627) and Lower (505628) Saw Blade Guard set for the Mark 5/V 500 works well on the Model 10's and provides a Lower Saw Blade Guard with a dust chute port. These come up for sale regularly on eBay but do make sure you are getting a complete set with all the parts. The upper Guard is sometimes missing the heavy wire loop called the "Shoe" which lifts the upper guard up and over the material being cut. Without the shoe the upper guard is unusable.

_

- 505627-505628r.jpg (61.58 KiB) Viewed 2675 times

.

I do realize the saw blade in the picture above is on backwards but it was taken that was to show the Shopsmith name on the blade.

The shoe is circled in red in the picture below.

_

- 505627 Upper and 505628 Lower Saw Blade Guards - shoe.jpg (129.35 KiB) Viewed 2675 times

Re: New Shopsmith Owner

Posted: Thu Oct 05, 2023 4:07 pm

by Restore

That looks like a great upgrade if for nothing else the dust collection, unfortunately I do not have access to metal cutting machinery "YET" but I did download your bracket file, thanks.

Question: For where light oil is recommended, I have been using the old 3-in-one oil and where light grease is called for, I have been using Lithium grease, do these seem like good choices for the 10ER or are there better options?

Also was thinking about using Dry lube on parts that are exposed to saw dust and was wondering if anyone has tried the dry lube on ways instead of wax and how that worked out?

My wife has accused me of having a new addiction to polishing SS parts….I don’t see it

Re: New Shopsmith Owner

Posted: Thu Oct 05, 2023 5:01 pm

by JPG

3in1 good fit. Lithium grease, I use it.

FWIW 'polished' thingies tend to slip when grasped. Look pretty though!!!

I think the wax is tried and true for decades now. Dry lube on lock threads(quill/way).

Re: New Shopsmith Owner

Posted: Fri Oct 06, 2023 12:17 am

by BuckeyeDennis

Ooooh … those are SHINY!

Floor wax (JPW, Minwax) on the lightly loaded stuff like way tubes.

For quadrant gears and fence locks, powdered graphite has served me extremely well.

On the quill and quill-gear shaft, I’ve had a few sticking problems. My best solution to date is to to hit them first with dry graphite, then with some powdered Teflon spray, and then with a shot or two of WD-40. The WD-40 isn’t a particularly good lubricant itself, but it seems to does a good job of dispersing the graphite and Teflon deep into the mechanicals, and it mostly evaporates in short order. I stay away from anything that will bind to sawdust.

Re: New Shopsmith Owner

Posted: Fri Oct 06, 2023 8:12 pm

by Restore

Thanks for the feedback, was concerned that I was not using the correct or optimal lubricants.

My new Drive bearings came in and I pressed them on the shaft with about a .01 gap between them and the spacer this time, thanks for the help as they feel correct this time around.

Re: New Shopsmith Owner

Posted: Fri Oct 06, 2023 9:30 pm

by Restore

This is a trivial question but it's bugging me as to why there is a hole in my SS cover plate, I thought it was supposed to be there for access/peep hole till noticing pics of other 10ER's don't have it. I knew the original owner and he would have had a good reason to put it there, any thoughts or guesses?

I don't believe is seances or Ouija boards to ask the Colonel why he did it so relying on the board.

Re: New Shopsmith Owner

Posted: Fri Oct 06, 2023 9:38 pm

by chapmanruss

Glad to hear you got the Drive Sleeve Assembly corrected.

The recommendations you have already received are good ones for lubricants. 3 in 1 oil is a good choice for the Floating Pulley and Bearings on a Speed Changer. I use White Lithium Grease on the Pinion Gear and Quill teeth. Easy to "clean up" if it collects sawdust and redo. As for a light coating of oil on bare metal parts as instructed in the Owner's Guide DON'T. Use the following addendum to supplant your original Owner's Guide recommendation.

_

Re: New Shopsmith Owner

Posted: Fri Oct 06, 2023 9:48 pm

by JPG

Hole in cover plate is for a power switch?

Re: New Shopsmith Owner

Posted: Fri Oct 06, 2023 10:21 pm

by Restore

Great idea, maybe he added an accessory switch for say a lamp or vacuum system at some point.