Page 4 of 6

Is the bearing too "loose"?

Posted: Sat Dec 29, 2012 11:44 am

by cllib

The bearing at the retaining loop seems loose.

Is it dry inside the bearing? Is it usable?

http://www.youtube.com/watch?v=ycSJ-yAy1Ds

http://www.youtube.com/watch?v=ycSJ-yAy1Ds

Posted: Sat Dec 29, 2012 12:12 pm

by backhertz

This bearing sounds dry & in my opinion should be replaced or lubricated somehow. Dry bearings will eventually burn & will turn a different color.

Sealed bearings should not just free spin like that unless they are dry or have been soaking in a solvent and all the lubricant is washed away.

Many moons ago when my family was in the roller skating business, we'd take Fafnir bearings, remove a metal cover and soak them in a solvent- gas. Then we'd relube them and mount them back in the wheels so the other shield was on the outside and they'd be used for a while. The skater would either save up money for new bearings or we'd just clean & regrease the old.

I've read some member have methods of getting oil into the bearing without removing the metal shield. But I just spun a new bearing and it did not spin like yours and make a sound. It was quiet and only spun a few times.

Posted: Sat Dec 29, 2012 3:17 pm

by cllib

backhertz wrote:This bearing sounds dry & in my opinion should be replaced or lubricated somehow. Dry bearings will eventually burn & will turn a different color.

Sealed bearings should not just free spin like that unless they are dry or have been soaking in a solvent and all the lubricant is washed away.

Many moons ago when my family was in the roller skating business, we'd take Fafnir bearings, remove a metal cover and soak them in a solvent- gas. Then we'd relube them and mount them back in the wheels so the other shield was on the outside and they'd be used for a while. The skater would either save up money for new bearings or we'd just clean & regrease the old.

I've read some member have methods of getting oil into the bearing without removing the metal shield. But I just spun a new bearing and it did not spin like yours and make a sound. It was quiet and only spun a few times.

Thanks for the information.

Posted: Sat Dec 29, 2012 11:49 pm

by JPG

[quote="cllib"]Thanks for the information. ]

'Replacing' the bearing will likely involve replacing the control sheave. The bearing is staked into the control sheave hub.

IIWM, I would submerge it in oil for an extended period.

It can get replentished when oiling the sheave if you raise it to vertical over night in the future.

There is little to no stress load on that bearing, so the main thing is that it turns. It does get side forces applied to it when decreasing speed.

Posted: Sun Dec 30, 2012 12:17 pm

by cllib

JPG40504 wrote:'Replacing' the bearing will likely involve replacing the control sheave. The bearing is staked into the control sheave hub.

IIWM, I would submerge it in oil for an extended period.

It can get replentished when oiling the sheave if you raise it to vertical over night in the future.

There is little to no stress load on that bearing, so the main thing is that it turns. It does get side forces applied to it when decreasing speed.

Thanks JPG.

Since I have more than one problem in the control sheave.

Other than its too freely ratating, there is a crack and the old sheave doesn't have a hole for oiling.

Do you think I just buy a new (used) one?

BiilMayo suggests to get a matched sheaves and shaft.

Posted: Sun Dec 30, 2012 9:34 pm

by JPG

cllib wrote:Thanks JPG.

Since I have more than one problem in the control sheave.

Other than its too freely ratating, there is a crack and the old sheave doesn't have a hole for oiling.

Do you think I just buy a new (used) one?

BiilMayo suggests to get a matched sheaves and shaft.

I would get a new control sheave and a new key. A new idler sheave would be 'better', but

if the existing one has little play on the existing key, I would not do so initially.

If however it does have considerable slop, a new one is indicated.

We do not know the age/history of yer parts(they could be 'original') so replacing all three parts is not unusual for their age.

However there is a 'gotcha' lurking here. If you gots a gilmer drive, there is no 'new' idler sheave available. Converting to poly-v adds the drive shaft and the quill,($$$$$$$$$$:eek:) and the belt.

Yes used Gilmer drive parts are common on E-Bay.

Gilmer Drive Torque Test a Success

Posted: Sat Jan 05, 2013 8:53 pm

by cllib

When I disassembled the gilmer had the metal plates and fiber washers put

OIOIOOII, similar to MickyD's IIOOIOIO. I=metal plate, O=Fiber Washer.

The original design had 5 interfaces. I decided to follow MikyD's layout, ie

IOIOIOIO, 7 interfaces. The reason is that I thought the spring is a little shorter than the new one, maybe have sonsumed somehow.

When I test, I use 15lb dumbbell put it at 11~13 inches away from the center.

It started to rotate.

I believe it's between 15lb~18.5lb. :-)

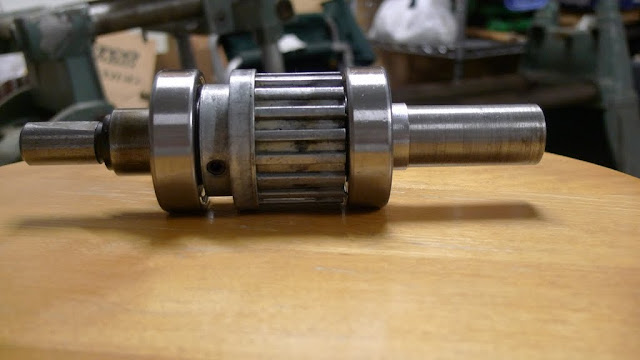

This is the picture I put the gilmer back in after sanded the plates and wasers

followed mickyD's method.

Posted: Sun Jan 06, 2013 12:03 pm

by JPG

1) You have waaay too much room in yer 'garage'.

2) The clamp/vicegrip are adding to the 'torque'.

3) Nicely done and documented.

4) Thanks

Gilmer Drive assembled

Posted: Sun Jan 06, 2013 1:54 pm

by cllib

With the USA bearing made in China. The Gilmer drive is reassembled.

The quill bearing feels good so I don't intent to replace it. There is one question about the quill bearing. Why the old one has so thin inner race? So if I remove it by the Harbourfreight Tool, will it be " damaged ?

Regarding " 1) You have waaay too much room in yer 'garage'."

It's a illusion because I use wide angle lens, 24mm, my "wife's" two car garage looks big. I had to have her car outside to do my restration.

Posted: Sun Jan 06, 2013 9:28 pm

by heathicus

I can buy that it's an optical illusion. The boards on that Workmate look about 6ft long!