Page 1 of 2

Clamping Pad Issue

Posted: Fri Jan 29, 2016 7:38 am

by berry

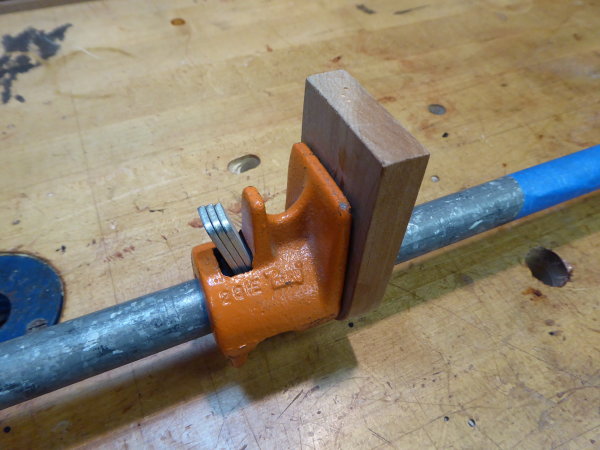

I use a few pipe clamps in my shop. A few years ago I read, in Wood Magazine a tip. It said you could easily made wood pads for pipe clamps and hold them in place with rare earth magnets. So I made them for my clamps. I glued the magnets into place with two part Loctite Epoxy. Three of the glue joints have failed, the magnets, coming out of the socket.

(pics attached) What did I do wrong?

- Pipe 475.jpg (64.68 KiB) Viewed 3775 times

- Pipe 474.jpg (85.83 KiB) Viewed 3775 times

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 7:51 am

by BuckeyeDennis

Here's some thoughts:

Did you clean the magnet well before gluing?

Are you gluing the sides of the magnet, and not just the back?

The pocket looks a bit oversized, although the epoxy should fill the gap. Does the magnet want a metric-size pocket?

Is the magnet proud of the pad? If so, the clamping forces might lead to glue-joint failure.

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 9:27 am

by JPG

You are using a magnet far stronger than was available a few years back?

Glue a thin 'face' over the magnet?

Epoxy does not stick to a smooth chrome plated surface?

Super glue?

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 11:53 am

by berry

I did not clean the magnets before gluing. But I'll try that next time.

The magnets sit slightly proud of the pad.

I'm pretty sure the magnets were Imperial sized, but not certain. I didn't think, and don't understand way, an oversize socket would matter?

I didn't try CA glue - I thought epoxy worked on everything?

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 12:01 pm

by ERLover

I use rare earths alot, I use epoxy, I have had that issue on some applications and some not, I give them a slight buffing with 220 grit and clean with alcohol, seems to work the best. I love those beast.

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 3:36 pm

by JPG

You have to be very discerning regarding the size. 6 mm does not equal 1/2 inch, but you see them identified as such. Also, proud gives you greater holding force

and greater pull out force when removing them.

Well fudd britches!!!!

I was not even close to what I was thinking about.

So "12mm does not equal 1/2" was what I previously encountered.

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 4:22 pm

by BuckeyeDennis

JPG wrote:You have to be very discerning regarding the size. 6 mm does not equal 1/2 inch, but you see them identified as such. Also, proud gives you greater holding force and greater pull out force when removing them.

Not even close!

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 4:34 pm

by ERLover

Its more like 12mm

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 5:04 pm

by JPG

ERLover wrote:Its more like 12mm

12.7!

Re: Clamping Pad Issue

Posted: Fri Jan 29, 2016 7:33 pm

by reible

I have glued in magnets like that with epoxy and they are still in place many years later. I wonder if the bond brakes when you use the clamps, with the magnet proud of the surface that is where the clamping force is going to be located and that being such a smaller area it will be quite concentrated at that point. It might be enough to cause what you are seeing.

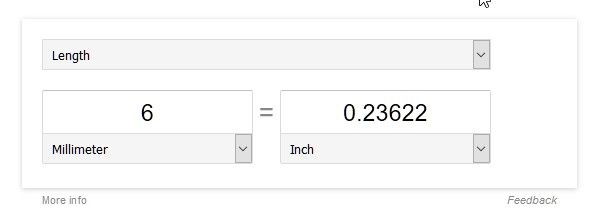

BTW if anyone has problems with metric to imperial measurements or the other way you can google it.

Start typing in something like "6mm=i" and it will have the answer for you:

- ScreenHunter_87 Jan. 29 18.28.jpg (9.12 KiB) Viewed 3598 times

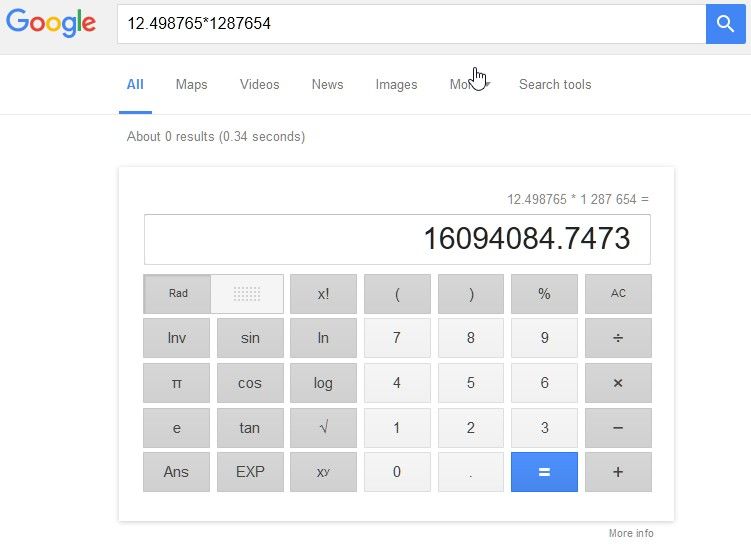

You can also do math:

- ScreenHunter_88 Jan. 29 18.31.jpg (33.05 KiB) Viewed 3598 times

So there is your tip for today.

Ed