Page 1 of 2

Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 1:10 am

by jjj240

I have a 510 headstock w/ 1-1/8 HP motor.

I've been using Freud 60 tooth "thin-kerf" blade (~$40) for most tasks (ripping, x-cutting).

Recently, I was given a fairly new OLD Shopsmith combination blade (50 tooth?) and I'd like to give it a try.

For 3/4" Plywood (feels pretty tough/hard... sheet w/ rough finish, got it from HD), my SS fed the sheet much slower than Freud, then eventually stalled and tripped the breaker after about 20" rip cut. The SS blade appears a full-kerf.

Is saw binding expected with a full-kerf blade on SS?

I am sure someone had been successful using SS w/ a full-kerf blade for hardwood (like walnut?) ... but I'd like to hear other experts' experience on full-kerf blades.

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 2:16 am

by dusty

I suspect that the blade (if it is sharp) has nothing to do with the binding. Cutting sheet goods on the Shopsmith is tricky. If it gets out of (your) control, it is inclined to bind.

Make absolutely certain that the rip fence and table tilt are locked and that you are keeping the work piece tight against the fence AND TABLE throughout the ENTIRE cut.

How does it work when cutting other than sheet goods.

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 6:38 am

by garys

I suspect that the blade isn't sharp enough. I've used full kerf blades to cut every kind of wood I can find and it works just fine.

Actually, the term "thin kerf" can be misleading. Some of the blades I own are marked "thin kerf" and yet I can't hardly measure the difference between them and the standard blades.

Yet, they all easily cut through oak and even solid hickory if they are sharp. I no longer will use any blade that isn't carbide. The carbide blades are so cheap today that I can't see using a non-carbide blade. Carbide cuts easier and cleaner and once they got cheap, why not use them all the time?

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 8:26 am

by algale

A properly set up Shopsmith will rip through properly prepared 3/4 stock no problem with a full kerf combo blade (assuming it isn't dull or dirty). I did it dozens of times before switching to thin kerf blades.

That said, if the plywood was warped or its reference edge wasn't straight, that could cause binding and, as Dusty points out, large sheets of plywood can be difficult to control.

I think I'd check the things Dusty mentions. I'd also check my table and fence alignment and make sure you you have a riving knife/upper saw guard in place.

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 8:51 am

by robinson46176

Always begin at the beginning...

The short list is:

Is the blade sharp?

Is the fence truly parallel to the blade?

Does it perform properly with a different blade?

Are you using an extension cord? You should avoid using one but if you must, use a 12 gauge one that is as short as you can use.

Are you sure that the outlet that you are plugged into is fed with at least 12 gauge wire?

Are you sure that that particular breaker is not weak/failing?

Are you holding your mouth right?

Good luck.

.

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 2:57 pm

by jjj240

Thanks for all your comments!

Yes, the blades are sharp.

I might add another statement in the original post. Freud thin-kerf blade ripped the same 3/4 sheet OK w/o bogging down.

Sine operator is the same (me), I guess I did the same attention/technique to feed the plywood for both blades. Yes, I understand that controlling a large sheet is tricky (and difficult) on SS.

Since smaller stock works fine w/ the full-kerf SS blade, I'd suspect it's more sensitive/trickier to deal with full-kerf blade on SS, and controlling larger stocks.

Happy New Year!

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 8:06 pm

by BuckeyeDennis

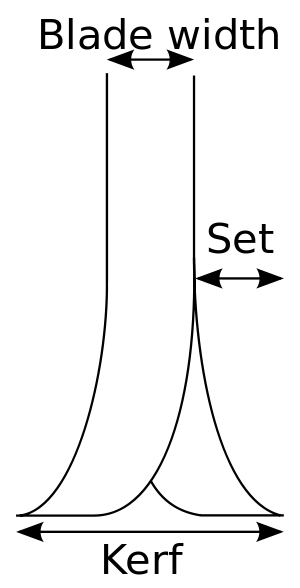

Does the old blade have steel teeth, or carbide? If it’s overly sensitive to alignment, the tooth set may be insufficient. Especially if steel teeth, it could be a bad sharpening job. Zero set = disc brake.

- 5E0328C6-5853-4E3B-AEB6-3CEDEB8A75A8.png (14.36 KiB) Viewed 21041 times

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Mon Jan 01, 2018 10:32 pm

by jjj240

Ohh, I forgot to mention.

Both blades are carbide tips.

I will upload pictures tomorrow (for future reference for other users).

BuckeyeDennis wrote:Does the old blade have steel teeth, or carbide? If it’s overly sensitive to alignment, the tooth set may be insufficient. Especially if steel teeth, it could be a bad sharpening job. Zero set = disc brake.

5E0328C6-5853-4E3B-AEB6-3CEDEB8A75A8.png

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Tue Jan 02, 2018 5:50 pm

by Hobbyman2

Are the blades the same dia ?

Re: Shopsmith Saw binding (bog down, trip breaker)

Posted: Wed Jan 03, 2018 1:03 pm

by jjj240

Both blades are 10'.

Here're pictures. (kerf comparison may not show that well, but Freud is thinner).

Are carbide tips dull? (it appears pretty sharp to me... :-)