Page 1 of 2

Need Advice Turning a 3 1/2 " Mortise

Posted: Fri Dec 25, 2020 5:48 pm

by Lodgepole

I am turning a 6"x6" wood cylinder between centers. I need to turn a 3 1/2" diameter x 1/2" deep mortise in one end. The mortise will need to have straight walls and a flat bottom. Due to the width of the headstock and tailstock I cannot get a turning chisel to go into the cylinder straight. I can only seem to get them to go in at an angle.

Is there any way of turning this mortise without using a lathe chuck on the other end? Any suggestions will be greatly appreciated.

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Fri Dec 25, 2020 6:22 pm

by rpd

You could use a face plate and a glue block

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Fri Dec 25, 2020 9:21 pm

by edflorence

How long is the 6x6? Ron's idea is on the right track, but if the workpiece is more than a few inches long I think you will need some sort of steady rest on the tail end. Maybe instead of the lathe you could use a fly cutter in the drill press mode with the work piece vertical and clamped to the vertically positioned table. That would require chisel and router work to clean up after the drilling, but 1/2 inch isn't too deep, so it I think it could be done that way.

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Sat Dec 26, 2020 3:23 pm

by wa2crk

Forstner bit???

Bill V

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Sat Dec 26, 2020 5:37 pm

by JPG

wa2crk wrote: ↑Sat Dec 26, 2020 3:23 pm

Forstner bit???

Bill V

3 1/2 inch?????? $$$$$$$

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Sat Dec 26, 2020 6:12 pm

by reible

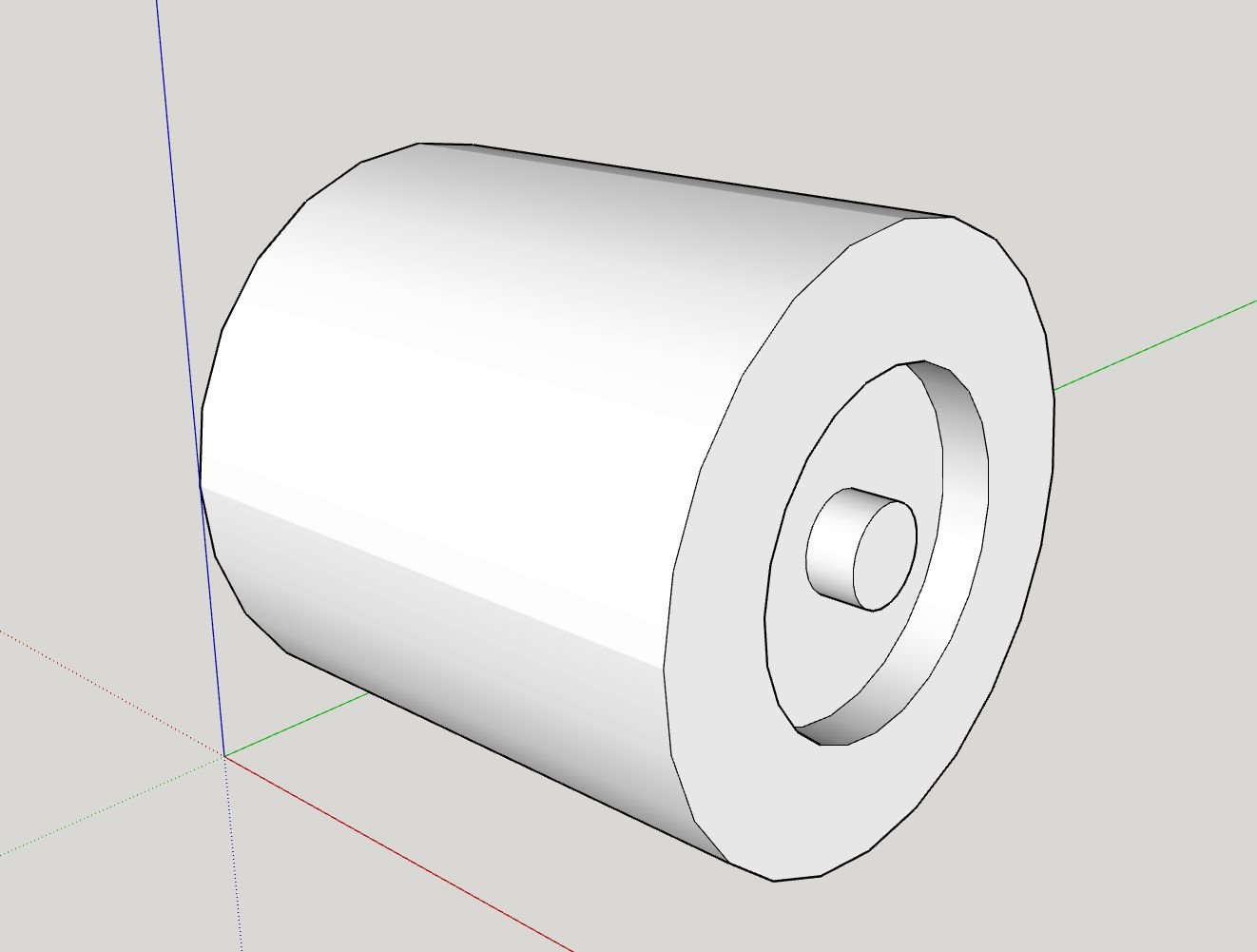

Without actually doing this I can't see any issues with just turning it with centers then removing the center section left for the tail stock center any way you can.

This is what I'm picturing:

- turning.jpg (62.91 KiB) Viewed 4486 times

If you are short of room then you may want to get a tail stock extension like this:

- lathe tail stock.jpg (154.43 KiB) Viewed 4486 times

Does that help?

Ed

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Sat Dec 26, 2020 6:26 pm

by RFGuy

IF the 6" x 6" cylinder is mounted securely in a lathe chuck or a faceplate, then no tailstock is needed so plenty of room to get a chisel in to cut the tenon. Ron and Ed Florence already suggested this. However, if this isn't possible you can always get a slim tailstock live center and extension to do as Ed suggests. It may still be hard to get the angle to have clean tenon shoulders and you'll have to remove the tailstock at some point to finish the center of the tenon. Just my 1.5¢...

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Sat Dec 26, 2020 7:31 pm

by reible

Do keep in mind this is something that is done all the time when turning things like bowls. You often need to turn a place for the spigot of a lathe chuck to fit and while they might not be as large as this it still the same process. In fact you often need to make a dovetail cut like this which is beyound the straight cut ask for here.

Ed

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Sat Dec 26, 2020 8:01 pm

by edma194

JPG wrote: ↑Sat Dec 26, 2020 5:37 pm

wa2crk wrote: ↑Sat Dec 26, 2020 3:23 pm

Forstner bit???

Bill V

3 1/2 inch?????? $$$$$$$

They're useful for so making so many other things like ... hockey puck holders?

Re: Need Advice Turning a 3 1/2 " Mortise

Posted: Sun Dec 27, 2020 10:45 am

by wa2crk

I have a 3" in my shop and we have a few in the club shop of 3 1/4 inch and 3 1/8 inch. One of our members who used to make clocks donated them.

Bill V

try this site

https://www.mlcswoodworking.com/shopsit ... orsbit.htm