Page 1 of 1

Dovetail/Box Joint jigs for Router

Posted: Wed Oct 26, 2022 2:28 pm

by bainin

Someone on a local NC board posted a Leigh D4R Pro Dovetail Jig (retail $800) for $350 with 12 router bits still sealed in wax.

Prior to this, I hadn't thought at all about a dovetail jig, now I cant get it out of my head

The deal was a mistake (posted in error he actually had a different Leigh jig) -but now I find myself looking at the various Jigs from Leigh, Porter Cable, Incra etc. Quite a variation in price..maybe not so much in capability.

Wondering if anyone here has gone down this rabbit hole?

This may be a case of me thinking that I would be making all kinds of dovetail joinery if I only had a jig haha.

b

Re: Dovetail/Box Joint jigs for Router

Posted: Wed Oct 26, 2022 2:58 pm

by twistsol

I've been using a Sommerfeld dovetail jig for about 10 years and have no complaints. It is easy to set up and accurate and under $250.00. It used to be the Katie Jig before they went out of business.

https://www.sommerfeldtools.com/Sommerf ... tinfo/DTJ/

I also have a Porter Cable fixed spacing half blind dovetail jig. I use it occasionally, but my Sommerfeld is my goto any time I build drawers.

Re: Dovetail/Box Joint jigs for Router

Posted: Wed Oct 26, 2022 3:16 pm

by DLB

twistsol wrote: ↑Wed Oct 26, 2022 2:58 pm

I've been using a Sommerfeld dovetail jig for about 10 years and have no complaints. It is easy to set up and accurate and under $250.00. It used to be the Katie Jig before they went out of business.

Other than being harder on bits, would you know why it is "Not recommended for use with plywood."? I wouldn't normally use plywood, but have seen some Baltic Birch that is more attractive stained than I might have expected...

- David

Re: Dovetail/Box Joint jigs for Router

Posted: Wed Oct 26, 2022 3:23 pm

by twistsol

It isn't generally recommended because the pins and tails are relatively weak when made from plywood or particle board. For plywood drawers, use either tongue & groove or dowels or dominos.

Re: Dovetail/Box Joint jigs for Router

Posted: Thu Oct 27, 2022 11:57 am

by Erik

Hi Banin,

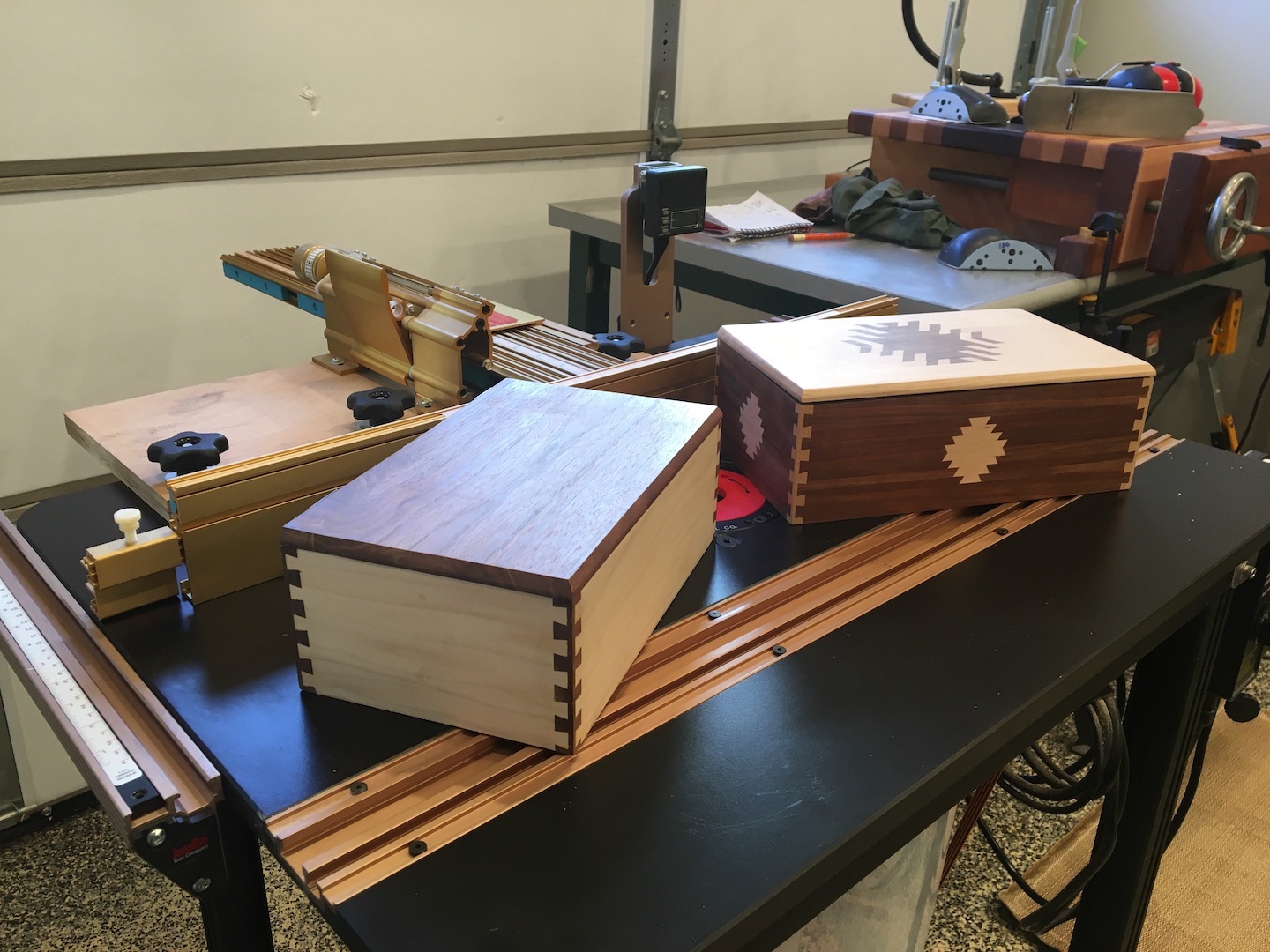

I purchased an Incra jig many years ago (maybe 25 years ago?) and have been very happy with it. The Incra system is different than some of the other systems in that you need a table setup, i.e. you are bringing the project to the table instead of bringing the jig to the project. That is actually what led me to buy it in the first place because I used it initially with a Mark V router table (about 5 years ago I bought a Jessem table that you see in the picture). The jig makes flawless dovetail and box joints and is my go-to fence system when making rabbits or sliding dovetails where I need to sneak up on a fit. Periodically I'll even clamp it down to my 520 table system if I am working on a finicky table saw cut because you can move the fence by 1/1000" using the micro adjuster. If there is any downside it would be that you are limited to dovetails on boards less than about 20" wide (I do 10" from one side and 10" from the other side) -- any wider than that and there is not enough travel on the carriage to span the work piece. A system that brings the jig to the wood would work better for those situations. That's never been a limitation for me because I usually only make dovetails and box joints on boxes and drawers.

-Erik

- Incra system attached to Jessem router table

- 2022 1027 Incra Dovetail and Box Joint Jig.jpeg (425.58 KiB) Viewed 2965 times

- Closeup of dovetail joint (box walls are about 1/2" thick)

- 2022 1027 Close up of Router Box Dovetail Joint.jpeg (359.47 KiB) Viewed 2965 times

Re: Dovetail/Box Joint jigs for Router

Posted: Thu Oct 27, 2022 2:07 pm

by bainin

Cant argue with those results Erik !

Would that be one of those LS Positioner jigs?

b

Re: Dovetail/Box Joint jigs for Router

Posted: Thu Oct 27, 2022 2:36 pm

by Erik

Yes. My system was called the "Ultra", but it has been superseded by the "LS Positioner". If you go with Incra you might find the attached bit-height calculations handy. One of the first things you do is set the bit hight to get a snug fit. Incra suggests a bit height and then has you sneak up on a tight fitting joint from that point. I got to thinking one day that if I knew the exact fit I could probably back off 10/1000" and hit it the first time. So I built the attached spreadsheet to help me get it right the first time. I still do a test piece, but have found that I hit it perfectly on the first try and don't need several iterations to get there. The bits/depths with the green check are ones that I have actually used in various projects.

-Erik