Expanding Worktable project

Moderator: admin

- wannabewoodworker

- Platinum Member

- Posts: 626

- Joined: Mon Feb 15, 2010 11:36 am

- Location: Milford, CT

Expanding Worktable project

Well I received my order from Rockler today with all of the T-Track and hardware for the Expanding Worktable that was featured in the latest issue of Shopnotes magazine. I am getting pretty antsy to finish it but I have also been obsessing over how i am going to move this behemoth around. I know I wnated to use casters but that would mean 8 casters and they would have to be locking and those things are expensive. Plus I really wanted the table to be stable when in use. So I have been looking around for some type of retractable caster arrangement for the table similar to the SS. I was browsing the Lumber Jocks website and found a thread talking about retractable casters for a table. The guy's had posted some links and one of them linked to a YouTube video of an ingenious design for very simple retractable casters for my expanding table. The great thing is I already have nice casters I got for nothing from some computer cabinets at one of my clients. This should work perfectly so now it is only time that is killing me. The cold hasn't helped either as I have no heat in the garage. But it is warming up by the day.

Michael Mayo

Senior IT Support Engineer

Soft Designs Inc.

albiemanmike@gmail.com

1960's SS Mark VII, 1954 Greenie, 1983 Mark V, Jointer, Bandsaw, Jigsaw, Dewalt Slider, Delta Super 10, Delta 8" Grinder, Craftsman compressor, Drill Doctor, Kreg PH Jig, Bosch Jigsaw, Craftsman Router and Table...........and adding more all the time....

Senior IT Support Engineer

Soft Designs Inc.

albiemanmike@gmail.com

1960's SS Mark VII, 1954 Greenie, 1983 Mark V, Jointer, Bandsaw, Jigsaw, Dewalt Slider, Delta Super 10, Delta 8" Grinder, Craftsman compressor, Drill Doctor, Kreg PH Jig, Bosch Jigsaw, Craftsman Router and Table...........and adding more all the time....

Hey all, new to this forum and the proud recipiant of a hand-me-down SS 500 built in 1979. Dad used the heck out of it but now has a full shop and found it in his heart to give me his old SS.

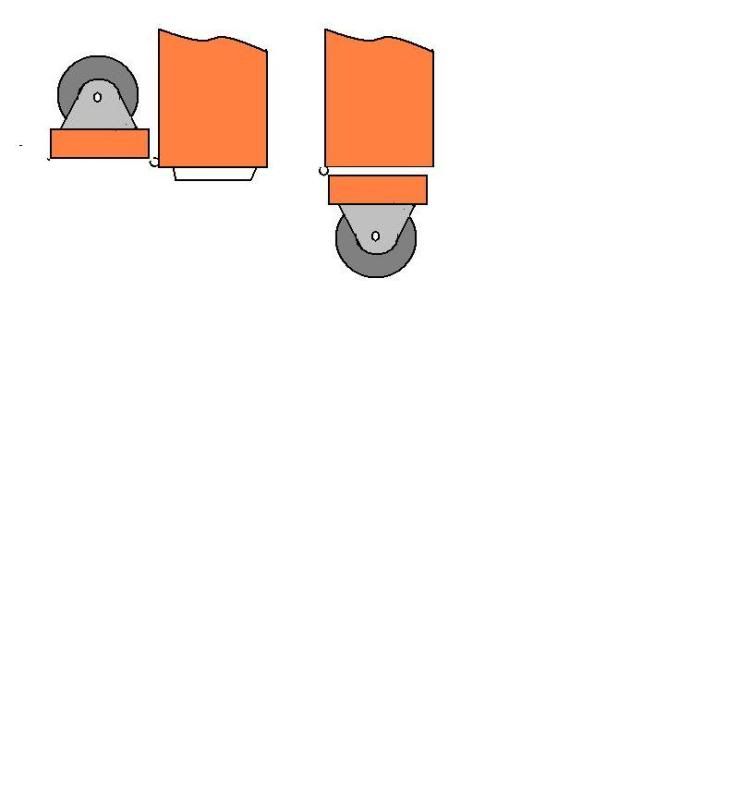

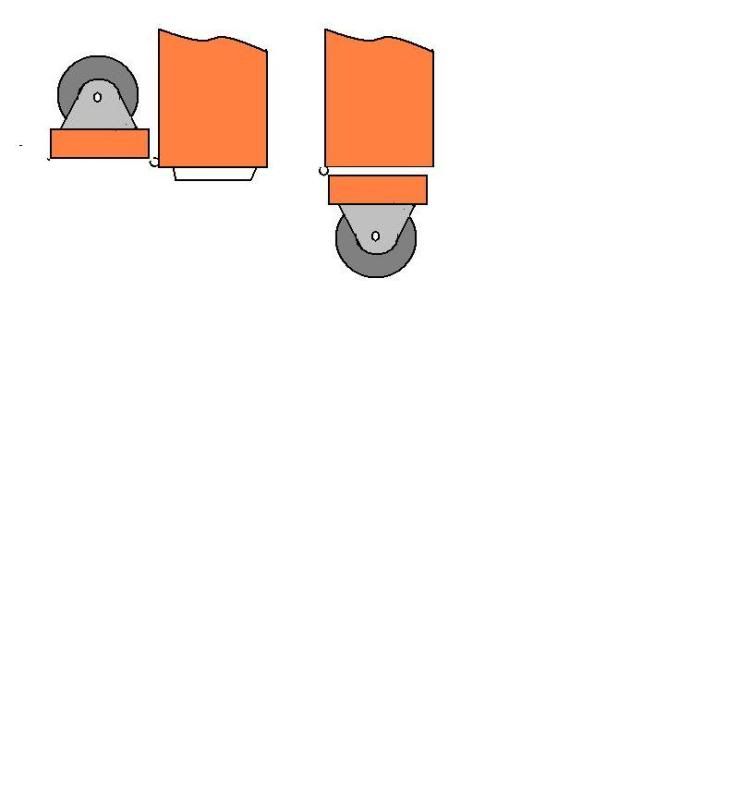

Unfortunately, I can't view the YouTube video from this location so please excuse any duplication. I saw this set up in the project gallery and thought it was a neat way to have your cake and eat it too:

If the flippable caster mount were cutout in the center, it would could clear a permanent rubber foot. This would provide some isolation from vibration. There may be spring loaded hinges out there that will hold the casters up by the leg while not in use. Just a thought.

Unfortunately, I can't view the YouTube video from this location so please excuse any duplication. I saw this set up in the project gallery and thought it was a neat way to have your cake and eat it too:

If the flippable caster mount were cutout in the center, it would could clear a permanent rubber foot. This would provide some isolation from vibration. There may be spring loaded hinges out there that will hold the casters up by the leg while not in use. Just a thought.