won't cut bevel. blade binding.

Moderator: admin

won't cut bevel. blade binding.

i can not figure out how to make a bevel cut on the shopsmith. i have table tilted, not touching blade, wood securely held in place on miter gauge. however, it will cut half way, then stop cutting. start burning the wood.

i reckon that bevel jig is all i can do.

i reckon that bevel jig is all i can do.

Dr says i only have about 40-50 more years to live

-

justplaingoofy

- Silver Member

- Posts: 16

- Joined: Wed Apr 20, 2011 4:38 pm

- Location: Canton, Ohio

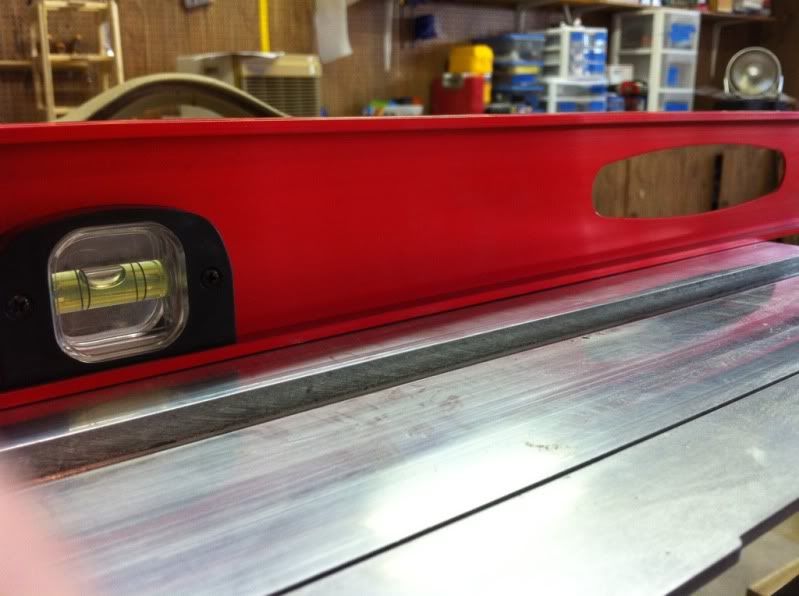

Bevel cut or not, if you are burning wood your blade may not be parallel to your table slots.

Another cause is possibly your blade? Worn? Especially blades that are not carbide tipped and have the 'set' just stamped out, they can start to rub and cause friction. I see guys use those worn steel blades in circular saws and make more smoke than sawdust.

Try having the blade only stick up far enough so it will cut thru too?

Time for some troubleshooting for sure.

Another cause is possibly your blade? Worn? Especially blades that are not carbide tipped and have the 'set' just stamped out, they can start to rub and cause friction. I see guys use those worn steel blades in circular saws and make more smoke than sawdust.

Try having the blade only stick up far enough so it will cut thru too?

Time for some troubleshooting for sure.

"Don't Be So Open Minded That Your Brains Fall Out"

1959 SS Mark V w/all attachments; 2 Craftsman 100 Table Saws; Delta 40-A Multiplex RAS; 6" Jet Jointer; Delta HomeCraft Floor and Bench Drill Presses; Dremel Everything; Rigid Dust Collector; and a vast collection of hand tools.

1959 SS Mark V w/all attachments; 2 Craftsman 100 Table Saws; Delta 40-A Multiplex RAS; 6" Jet Jointer; Delta HomeCraft Floor and Bench Drill Presses; Dremel Everything; Rigid Dust Collector; and a vast collection of hand tools.

Carbide blade. Tried both blade hights. Barely to top, and beyond wood by one tooth.justplaingoofy wrote:Bevel cut or not, if you are burning wood your blade may not be parallel to your table slots.

Another cause is possibly your blade? Worn? Especially blades that are not carbide tipped and have the 'set' just stamped out, they can start to rub and cause friction. I see guys use those worn steel blades in circular saws and make more smoke than sawdust.

Try having the blade only stick up far enough so it will cut thru too?

Time for some troubleshooting for sure.

Table being square to blade. Did not think of that yet. I will have a loom see tomorrow.

Dr says i only have about 40-50 more years to live

- JPG

- Platinum Member

- Posts: 35430

- Joined: Wed Dec 10, 2008 7:42 pm

- Location: Lexington, Ky (TAMECAT territory)

We need to come to a common understanding of what we be referring to.

First the levelness of the table has no bearing on the following:

Square to the blade is more than one thing. It should be square in two planes.

First one is the squareness to the blade as determined by placing a square between the table and the vertical surface of the blade. That assures that when the trunion is set to 0 degrees, the blade will cut a square profile across the edge.

Second one is less obvious. It is also the one that may cause your binding blade. The table miter gauge slots must be parallel with the outer face of the blade. This ensures that the workpiece moves parallel to the blade as it is being cut. If the slots are skewed to the blade, the kerf in the workpiece will move in a biased direction causing the side of the kerf to move into the blade. This becomes more pronounced the further the cut is made.

That assumes use of the miter gauge, but the rip fence must also be parallel(square to the blade) since a more severe binding condition exists as the rip fence adds a bind at the edge against the fence to the one on the blade end.

The riving knife must be centered in the blade kerf. It's position will vary depending upon the blade.

Bottom line: You do not want ANY rubbing of the newly cut edges on anything(.)!

Now about your 'bevel' cut. Are you tilting the table, setting the miter gauge for an angle cut, or both?

First the levelness of the table has no bearing on the following:

Square to the blade is more than one thing. It should be square in two planes.

First one is the squareness to the blade as determined by placing a square between the table and the vertical surface of the blade. That assures that when the trunion is set to 0 degrees, the blade will cut a square profile across the edge.

Second one is less obvious. It is also the one that may cause your binding blade. The table miter gauge slots must be parallel with the outer face of the blade. This ensures that the workpiece moves parallel to the blade as it is being cut. If the slots are skewed to the blade, the kerf in the workpiece will move in a biased direction causing the side of the kerf to move into the blade. This becomes more pronounced the further the cut is made.

That assumes use of the miter gauge, but the rip fence must also be parallel(square to the blade) since a more severe binding condition exists as the rip fence adds a bind at the edge against the fence to the one on the blade end.

The riving knife must be centered in the blade kerf. It's position will vary depending upon the blade.

Bottom line: You do not want ANY rubbing of the newly cut edges on anything(.)!

Now about your 'bevel' cut. Are you tilting the table, setting the miter gauge for an angle cut, or both?

╔═══╗

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

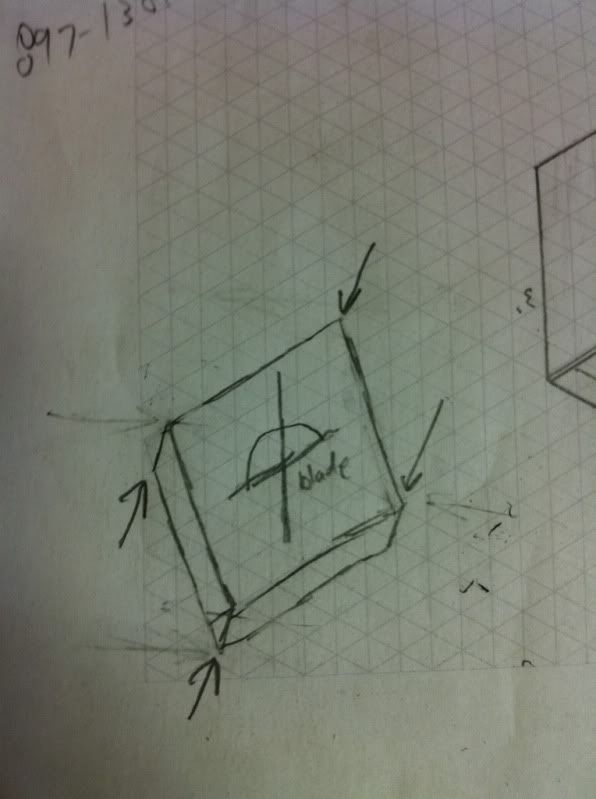

That is what I mean by square with the blade. Perpendicular and vertical. If one is off then it is not "square" as a general term. Not "true"

So, the table is square with the blade.

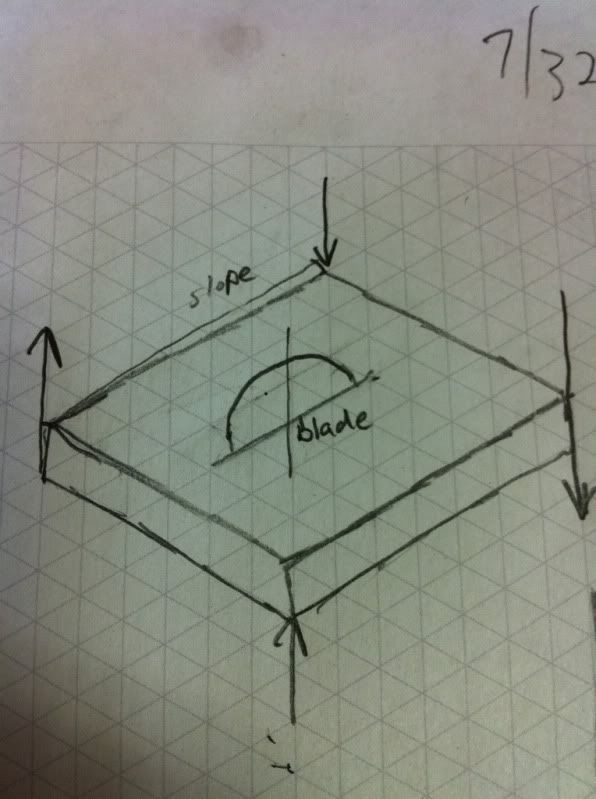

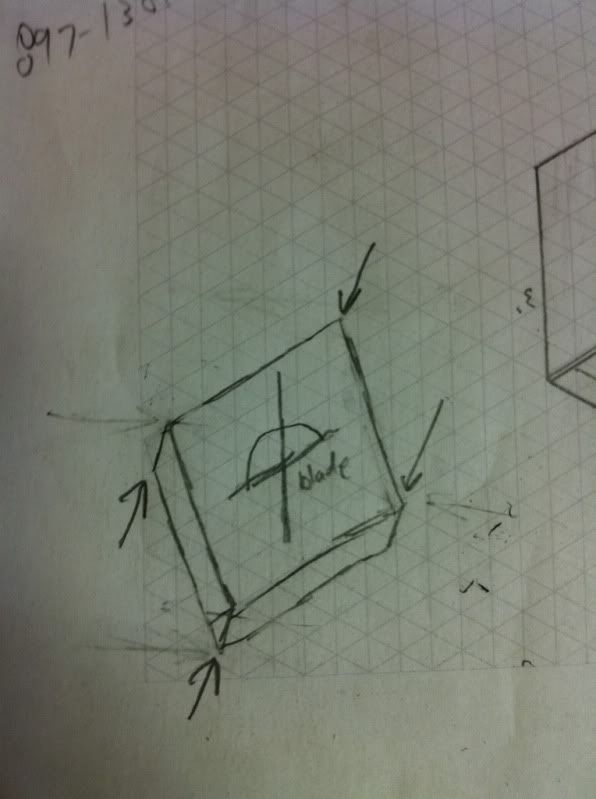

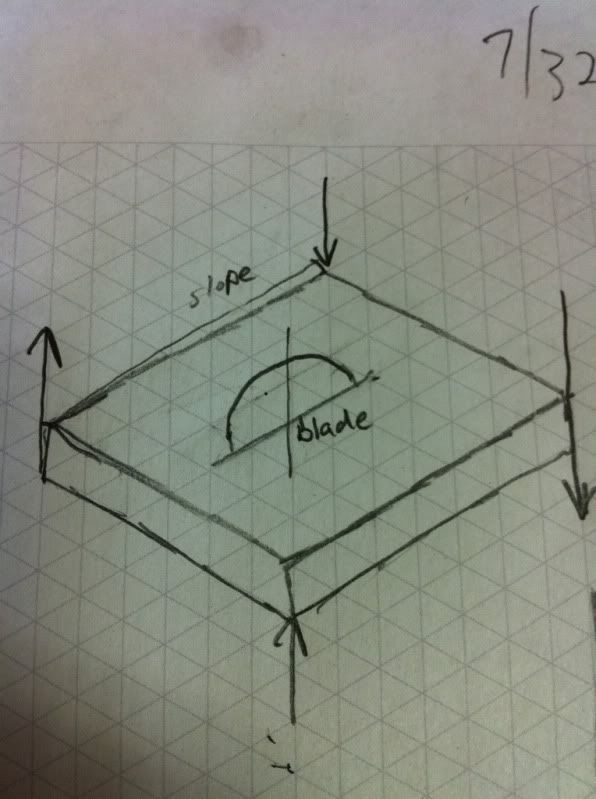

But, not with the earth. No imagine the direction of slope as an arrow. With the table at 0 deg, the direction of slope does not intersect the blades vertical plane. Table is true in relation to blade.

However, when the table is tilted on the axis of the slope (side to side in this case) then the direction of the slope opposes the vertical position of

The blade. The table is no longer true to the blade.

But I believe I have leveled the table, I will have to see.

So, the table is square with the blade.

But, not with the earth. No imagine the direction of slope as an arrow. With the table at 0 deg, the direction of slope does not intersect the blades vertical plane. Table is true in relation to blade.

However, when the table is tilted on the axis of the slope (side to side in this case) then the direction of the slope opposes the vertical position of

The blade. The table is no longer true to the blade.

But I believe I have leveled the table, I will have to see.

Dr says i only have about 40-50 more years to live

- JPG

- Platinum Member

- Posts: 35430

- Joined: Wed Dec 10, 2008 7:42 pm

- Location: Lexington, Ky (TAMECAT territory)

Thank you for that answer(not a compound angle cut!).gat_76 wrote:Oh, and I had table tilted, clamped in miter gauge. 0deg (90deg cut)

We need to distinguish between flat and level.

Yes the table needs to be flat, and shimming the mounting bolts will accomplish that(assuming no warping). Being flat is not the same as level. When you 'tilt' the table with the trunion, it is not level, but is sill flat.

A 'level' table is square to the blade(vertically) only if the blade is vertical(plumb).

The second square to the blade requirement is totally independent of all that above. It is also the likely cause(lack of it) that is causing your binding.

╔═══╗

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange